My RB26 240z Build

-

boostedh23a1

- Posts: 281

- Joined: Tue Oct 17, 2006 1:37 pm

- Car: Datsun 240Z

Datsun 280Z - Location: Beaufort, SC

Re: My RB26 240z Build

Lost the clutch at 300tq so we couldnt do much more full throttle. Have to get a clutch and go back... Shouldnt be anything special as the motor is pretty much stock.

- evildky

- Posts: 14713

- Joined: Sat Jan 31, 2004 9:23 pm

- Car: 71 240ZT, 87 300ZXN/A-T, 06 350Z GT, Tundra TRD RW

- Location: Louisville, KY

- Contact:

Re: My RB26 240z Build

so 300 lbft, how much hp?

trying to figure out why you'd post a vid and tell us boost levels without adding hp/tq numbers?

trying to figure out why you'd post a vid and tell us boost levels without adding hp/tq numbers?

-

boostedh23a1

- Posts: 281

- Joined: Tue Oct 17, 2006 1:37 pm

- Car: Datsun 240Z

Datsun 280Z - Location: Beaufort, SC

Re: My RB26 240z Build

To keep you coming back :p

330hp 300tq but still have a ways to go, not expecting much though.

330hp 300tq but still have a ways to go, not expecting much though.

Re: My RB26 240z Build

That dash turned out looking really great. Nice work.

-

boostedh23a1

- Posts: 281

- Joined: Tue Oct 17, 2006 1:37 pm

- Car: Datsun 240Z

Datsun 280Z - Location: Beaufort, SC

Re: My RB26 240z Build

Well, i just lost the oil pump i think. Hopefully the motor will be ok, not sure. Dont hear a rod knocking yet. Ehhh my life blows.

-

boostedh23a1

- Posts: 281

- Joined: Tue Oct 17, 2006 1:37 pm

- Car: Datsun 240Z

Datsun 280Z - Location: Beaufort, SC

Re: My RB26 240z Build

Got the transmission and oil pump out. Brand new N1 pump completly shattered. Clutch disk is totally shot. Ready to pull the oil pan all the way off and inspect the bearings. My luck is total s***, so I will probably be needing a rebuild, but i figured i would wait till tomorrow and drink myself to sleep tonight.

Re: My RB26 240z Build

That technique has worked for me many times and it's a lot easier to clean up that mess than if you lose it in your garage and start throwing stuff everywhere, which I have done as well.

-

boostedh23a1

- Posts: 281

- Joined: Tue Oct 17, 2006 1:37 pm

- Car: Datsun 240Z

Datsun 280Z - Location: Beaufort, SC

Re: My RB26 240z Build

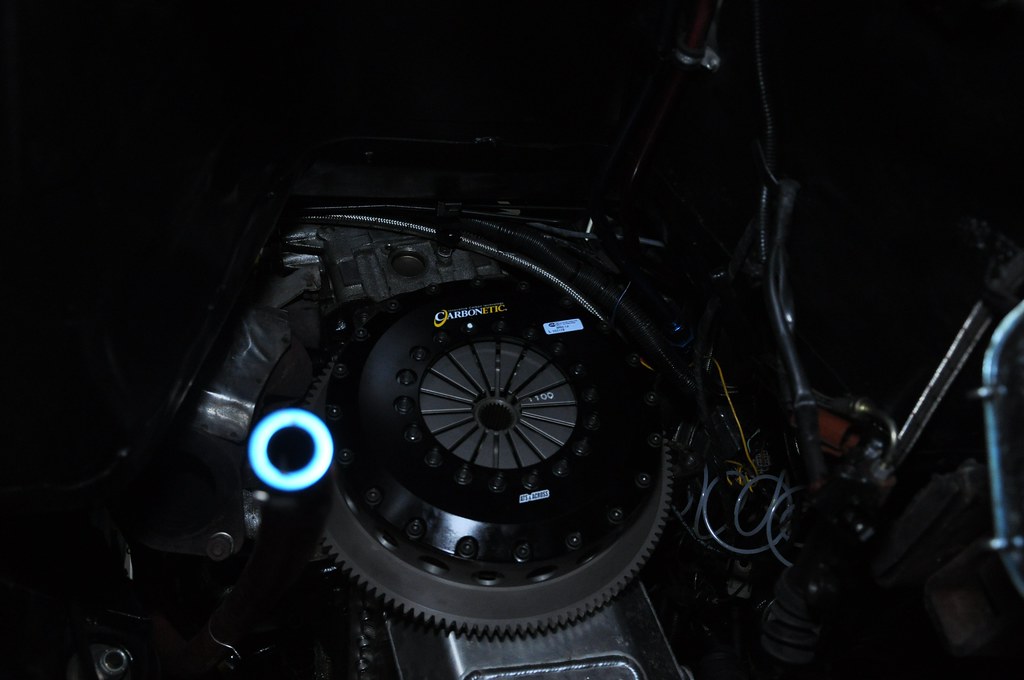

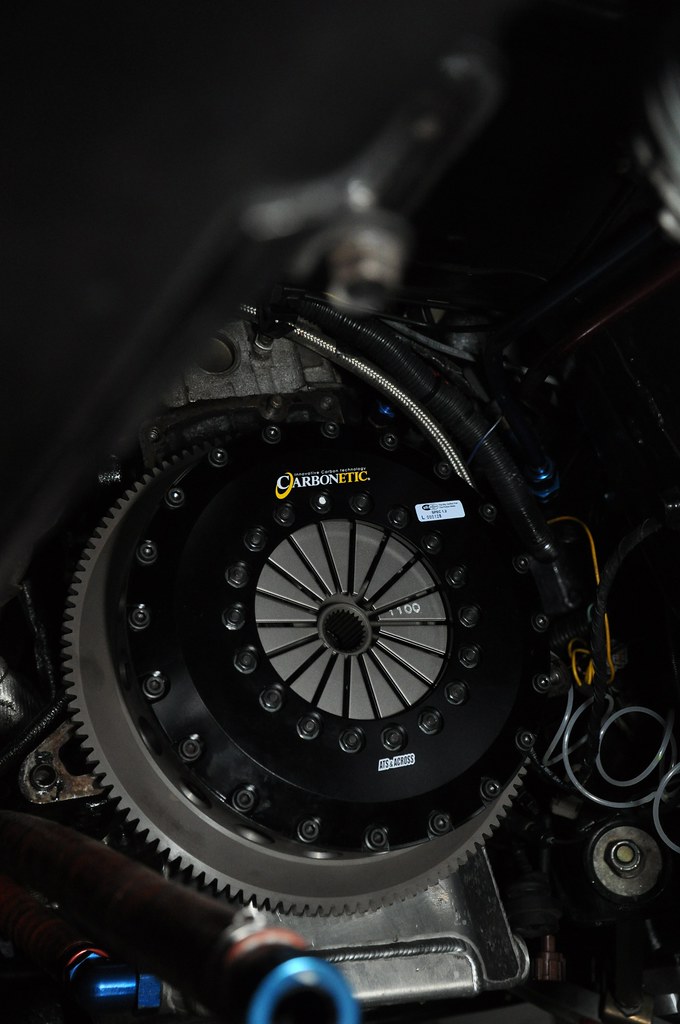

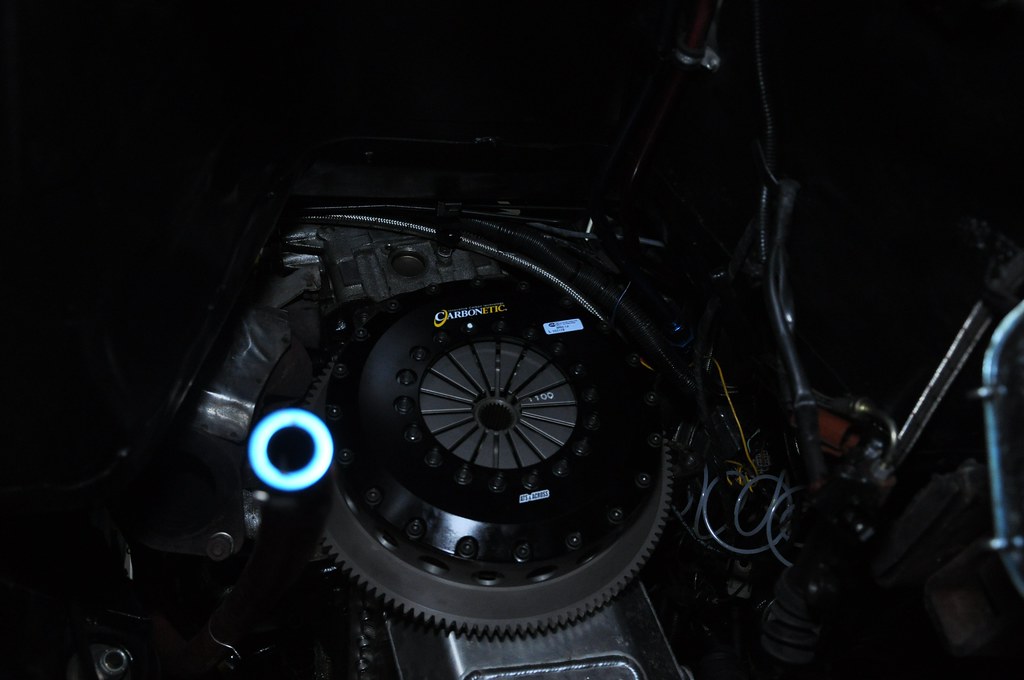

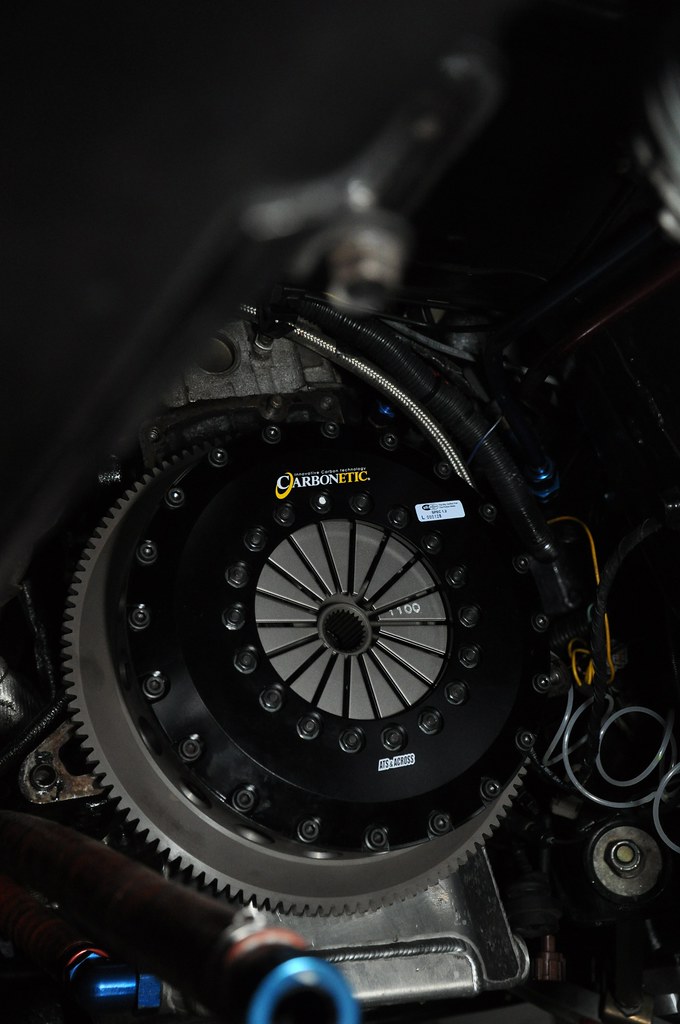

Clutch came in as well as all the conversion from pull to push.

-

boostedh23a1

- Posts: 281

- Joined: Tue Oct 17, 2006 1:37 pm

- Car: Datsun 240Z

Datsun 280Z - Location: Beaufort, SC

Re: My RB26 240z Build

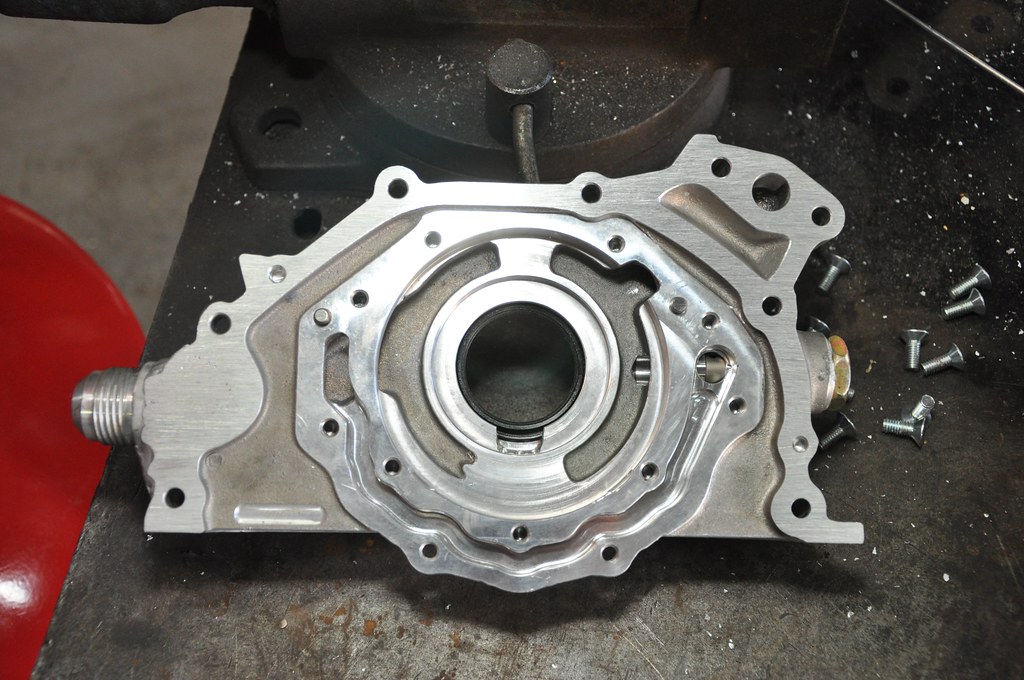

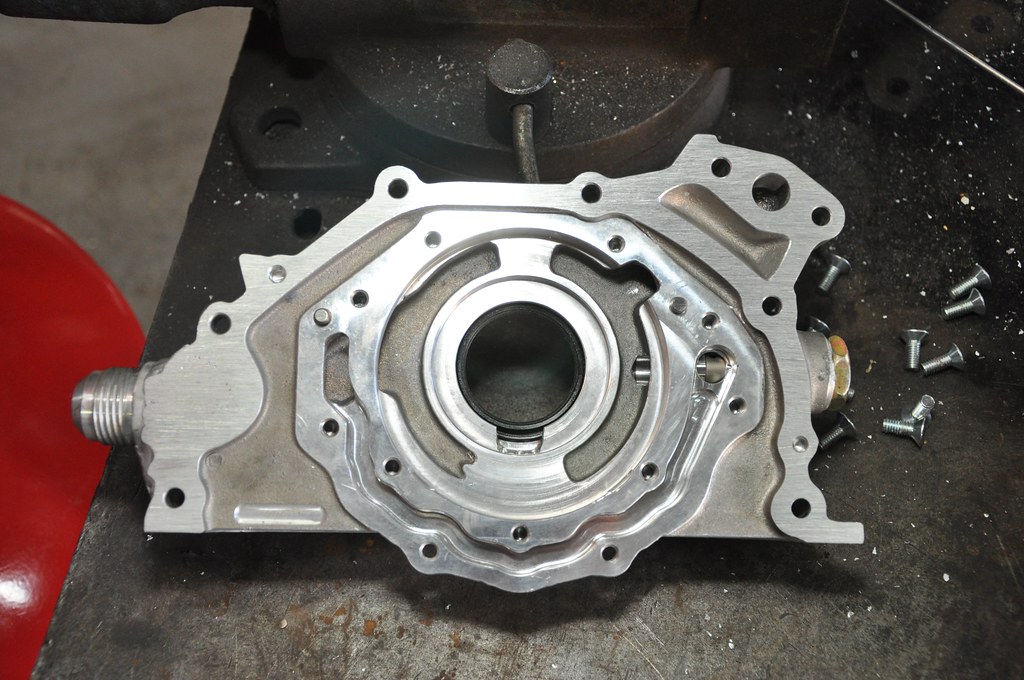

Well Here is the Tomei oil pump I just got done welding on. Holy crap that was the most nervous I have been Its only 1800 bux if you screw it up. Also the clutch bolted up.

-

boostedh23a1

- Posts: 281

- Joined: Tue Oct 17, 2006 1:37 pm

- Car: Datsun 240Z

Datsun 280Z - Location: Beaufort, SC

Re: My RB26 240z Build

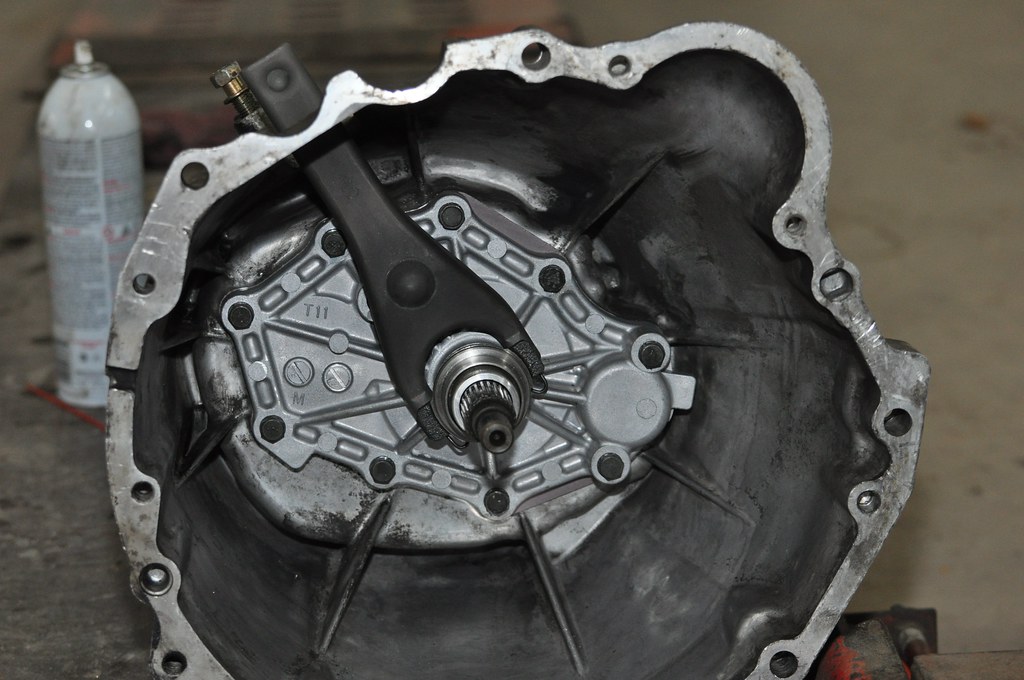

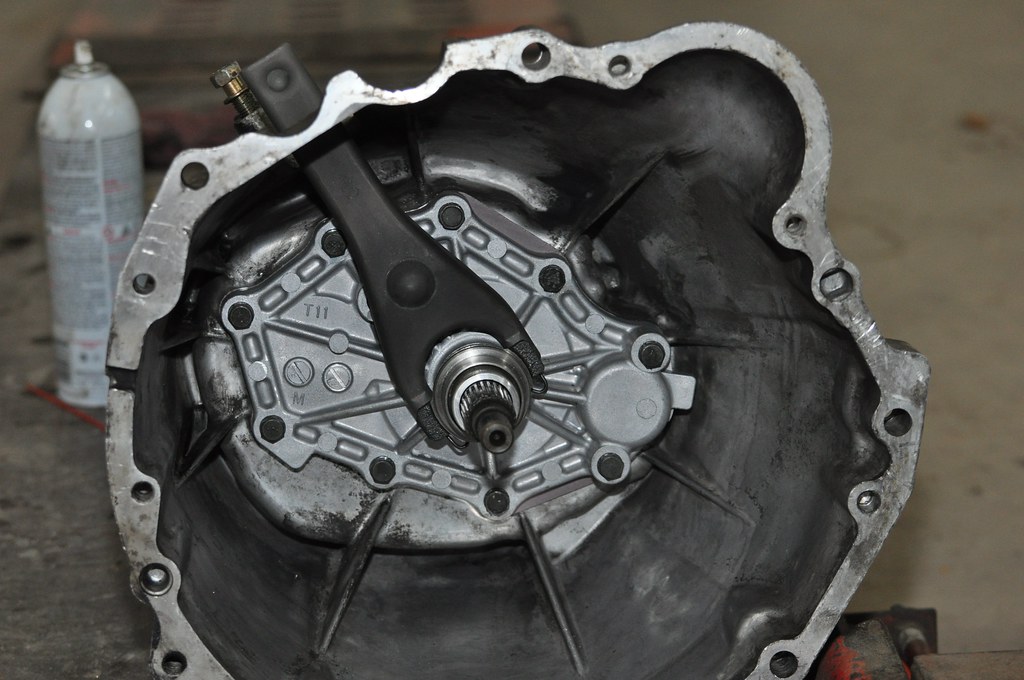

Pull to Push Conversion:

Parts needed:

32110-05U11 front cover assembly

32112-05U11 gasket front cover

30531-01S00 release fork

30534-E9000 spring (for pivot)

30514-14600 spring (for sleeve)

30502-14601 clutch bearing,

30501-S0200 bearing sleeve(18mm)

30542-31G10 cover dust,

30620-21U01 slave cylinder assembly,

30855-05U00 hose (but I used my old one from the pull)

The rear bolts are for the pull slave. You must drill and tap the front with 10mm X 1.50 tap.

Remove all the components from the pull style. Remove the front cover in the transmission and it will look like this.

Assemble the no brainer parts...

All done...

Parts needed:

32110-05U11 front cover assembly

32112-05U11 gasket front cover

30531-01S00 release fork

30534-E9000 spring (for pivot)

30514-14600 spring (for sleeve)

30502-14601 clutch bearing,

30501-S0200 bearing sleeve(18mm)

30542-31G10 cover dust,

30620-21U01 slave cylinder assembly,

30855-05U00 hose (but I used my old one from the pull)

The rear bolts are for the pull slave. You must drill and tap the front with 10mm X 1.50 tap.

Remove all the components from the pull style. Remove the front cover in the transmission and it will look like this.

Assemble the no brainer parts...

All done...

-

boostedh23a1

- Posts: 281

- Joined: Tue Oct 17, 2006 1:37 pm

- Car: Datsun 240Z

Datsun 280Z - Location: Beaufort, SC

Re: My RB26 240z Build

Back on the road for about a week now, seems ok. The clutch is pretty loud though. Cant have your cake and eat it too. Next up CCW Classics.

- evildky

- Posts: 14713

- Joined: Sat Jan 31, 2004 9:23 pm

- Car: 71 240ZT, 87 300ZXN/A-T, 06 350Z GT, Tundra TRD RW

- Location: Louisville, KY

- Contact:

Re: My RB26 240z Build

CCW's FTWboostedh23a1 wrote:Back on the road for about a week now, seems ok. The clutch is pretty loud though. Cant have your cake and eat it too. Next up CCW Classics.

-

boostedh23a1

- Posts: 281

- Joined: Tue Oct 17, 2006 1:37 pm

- Car: Datsun 240Z

Datsun 280Z - Location: Beaufort, SC

Re: My RB26 240z Build

CCW CLassics FBB (for breaking the bank)

- evildky

- Posts: 14713

- Joined: Sat Jan 31, 2004 9:23 pm

- Car: 71 240ZT, 87 300ZXN/A-T, 06 350Z GT, Tundra TRD RW

- Location: Louisville, KY

- Contact:

Re: My RB26 240z Build

they ain't cheap but when you want 12" wheels on a datsun, there is no off the shelf option, it's full custom only

-

boostedh23a1

- Posts: 281

- Joined: Tue Oct 17, 2006 1:37 pm

- Car: Datsun 240Z

Datsun 280Z - Location: Beaufort, SC

Re: My RB26 240z Build

I dont know if 12s are gonna fit.. maybe 11s at the most. I dont have those wide flares, i have the msa cf ones. I think i can run a 6 or maybe a 6.5 backspace but I gotta do some measuring 1st. Im worried about ride quality. I have the T3 suspension but i have the oem rubber isolators so to lower the car the spring perches will be on the pretty low side...

- evildky

- Posts: 14713

- Joined: Sat Jan 31, 2004 9:23 pm

- Car: 71 240ZT, 87 300ZXN/A-T, 06 350Z GT, Tundra TRD RW

- Location: Louisville, KY

- Contact:

Re: My RB26 240z Build

who needs flares? just a sawzall

true story, after adding the ccw's and triming to fit I changed spring rated in the rear to something a bit softer (350lb/in), and went to a devisional, I took my battery powered sawzall with me in case I needed to trim a bit more.... so I was cutting my fenders in the grid with a sawzall and it caused a bit of a crowd to form

I'd like to do the 280yz widebody but thats another 2 grand

fyi I'm running 17 x11 front with 295/40 17's and 17 x 12 rear with 315/35 17's

true story, after adding the ccw's and triming to fit I changed spring rated in the rear to something a bit softer (350lb/in), and went to a devisional, I took my battery powered sawzall with me in case I needed to trim a bit more.... so I was cutting my fenders in the grid with a sawzall and it caused a bit of a crowd to form

I'd like to do the 280yz widebody but thats another 2 grand

fyi I'm running 17 x11 front with 295/40 17's and 17 x 12 rear with 315/35 17's

-

boostedh23a1

- Posts: 281

- Joined: Tue Oct 17, 2006 1:37 pm

- Car: Datsun 240Z

Datsun 280Z - Location: Beaufort, SC

Re: My RB26 240z Build

Do you have any close pics? what kinda backspacing? how much clearance bettween the tire and your strut tubes/ coilovers?

- evildky

- Posts: 14713

- Joined: Sat Jan 31, 2004 9:23 pm

- Car: 71 240ZT, 87 300ZXN/A-T, 06 350Z GT, Tundra TRD RW

- Location: Louisville, KY

- Contact:

Re: My RB26 240z Build

I did the "standard backspacing" (talk to dave at CCW) yes coil overs, I have a pic somewhere I'll have to dig, there was at least another 1/4" maybe even 1/2" more backspacing I could have fit, the scrub radius is kinda rediculous

-

boostedh23a1

- Posts: 281

- Joined: Tue Oct 17, 2006 1:37 pm

- Car: Datsun 240Z

Datsun 280Z - Location: Beaufort, SC

Re: My RB26 240z Build

how does that scrub affect ya?

- evildky

- Posts: 14713

- Joined: Sat Jan 31, 2004 9:23 pm

- Car: 71 240ZT, 87 300ZXN/A-T, 06 350Z GT, Tundra TRD RW

- Location: Louisville, KY

- Contact:

Re: My RB26 240z Build

makes it real tough to steer at slow speeds or stopped, like parking, of course the quick steer knuckles and the smaller steering wheel add to the effort

-

boostedh23a1

- Posts: 281

- Joined: Tue Oct 17, 2006 1:37 pm

- Car: Datsun 240Z

Datsun 280Z - Location: Beaufort, SC

Re: My RB26 240z Build

Well, I ordered a Wilson 90mm throttle body. I sent it back and went with a 80mm. The action on both of them are sweet, much nicer than the one I have on there now. I am replacing it because it is sticking at idle and sticking at WOT... not good. I got a new lokar throttle cable and will post that write up as time goes. Anyway the Wilson flange is 88mm square flange and the flange i have on there now is 78mm square flange. I put the throttle body in the mill and elongated the holes to fit, sounds easier than it was but its done now. I also had to tap the TPS bolt holes on the 80mm which was odd because the 90mm came tapped already (4mmX.70). Anyway that is also done now. Hopefully I will get some time tomorrow to bolt it on. In the meantime here are some pics. 80mm is the smallest thing on my car, all the piping is 3" (90mm) but I dont want an on/off switch for a throttle body. Hope I did right...

-

boostedh23a1

- Posts: 281

- Joined: Tue Oct 17, 2006 1:37 pm

- Car: Datsun 240Z

Datsun 280Z - Location: Beaufort, SC

Re: My RB26 240z Build

Well I decided to finish up my exhaust last week or so ago. I took out the bottle style vibrant resonator and put in a vibrant ultra quiet resonator. It took out the drone at cruise and quieted it down some throughout the band. Im very pleased.

Currently sourcing some camery window regulators for power windows and i dont think this spal kit will last long. I am also getting ready to order the rear wheels. Hopefully they will be 17x12 but I will keep ya posted on that...

Currently sourcing some camery window regulators for power windows and i dont think this spal kit will last long. I am also getting ready to order the rear wheels. Hopefully they will be 17x12 but I will keep ya posted on that...

- Bigalow311

- Posts: 167

- Joined: Sat May 09, 2009 12:33 pm

- Car: Nissan 350z

Re: My RB26 240z Build

subscribed for later reading.

-

boostedh23a1

- Posts: 281

- Joined: Tue Oct 17, 2006 1:37 pm

- Car: Datsun 240Z

Datsun 280Z - Location: Beaufort, SC

Re: My RB26 240z Build

Well, it has been awhile since i have updated this and I have to admit that I have slacked off on the picture taking and all the baby steps in between all this. Anyway I have finished up the Toyota Camery power window regulators and they work pretty damn good i must say. I ended up having to mount the drivers side motor on the outside of the door shell (between the door shell and the door panel because the window would hit the motor. The passenger side couldnt possible fit any better. There is a slight bulge in my fiberglass door panel on the drivers side but its not really noticable unless your looking for it. Finally when people are motioning to roll down the window i dont have to yell THEY ARENT POWER!!. My stock window regulars left much to be desired and with these camery ones its actually a weight reduction... Win Win. Also installed all new window felt and seals, damn that stuff is expensive...

Got my 17x10.5 CCW classics for the rear. I took the car down to John at CCW and we(he really) did all the guess work. I am running Kuhmo Escta XS 295/35/17 tires which grip pretty good if you warm em up a touch. Once i get the car stanced right i will run the track out a touch via the lower conrol arms. I probably could have squeezed a 17x11 in there.

Here is is where i am hoping my ride height will be once I install my T3 camber plates.

Here is where it is now.

Got the intake fabbed up and finished, finally and also mounted the fender mirrors.

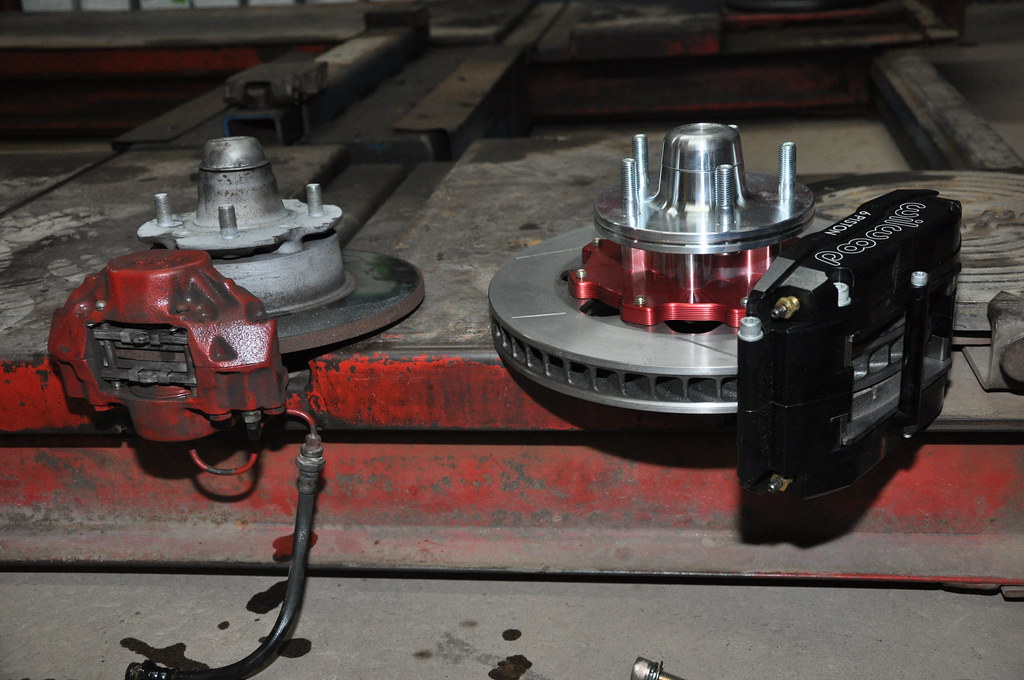

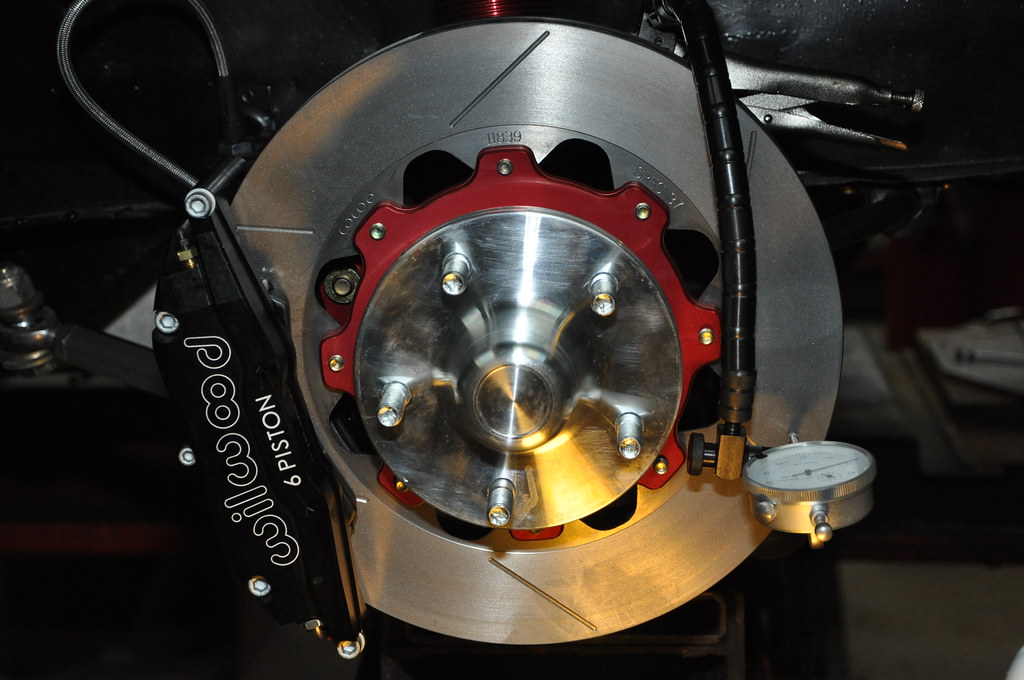

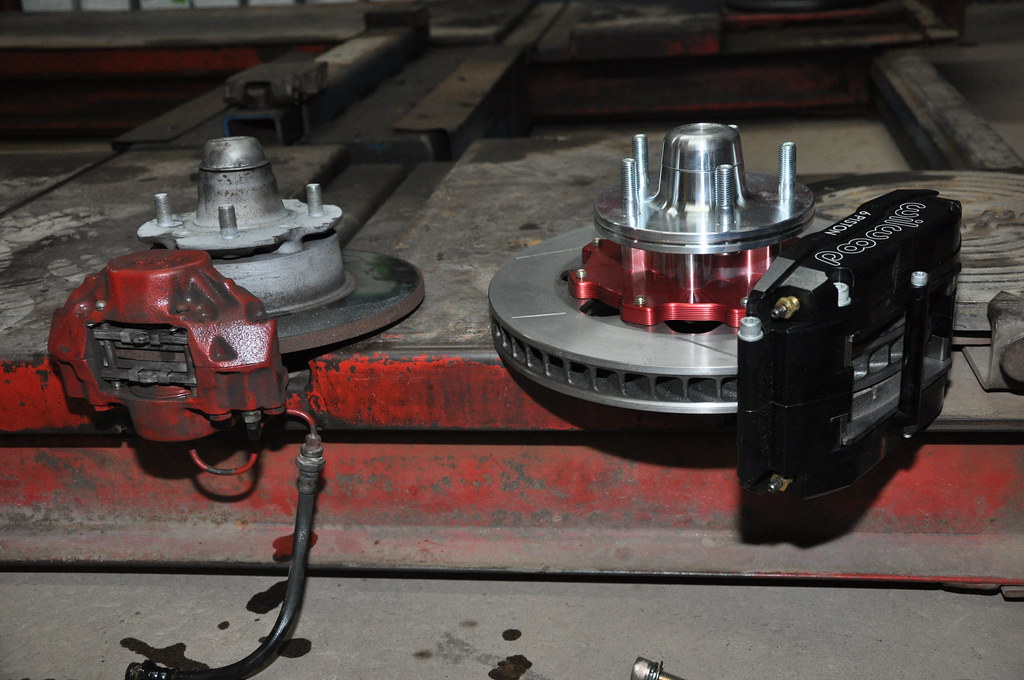

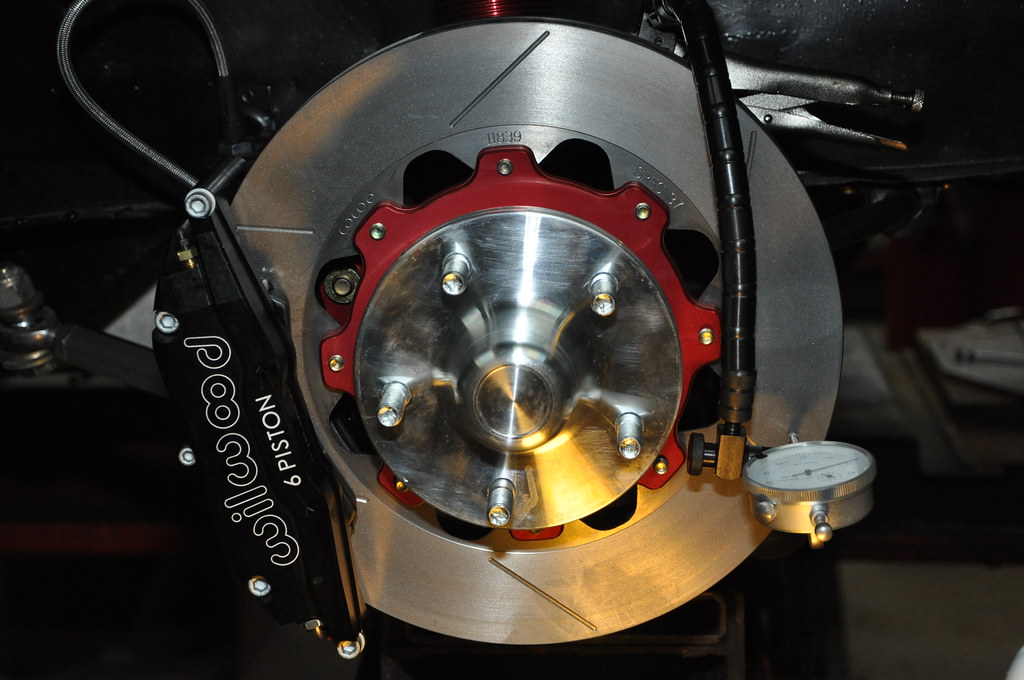

Installed new door seals, that was a pain... Ordered the AZC big brake kit with oversized rotors and 6 piston calipers and the 5 lug hubs. He said he doesn't recommend using the 13" on the 5 lug aluminum hubs because of the extra weight, so I went with the thicker 12.2" he has two different versions apparently.

Got my 17x10.5 CCW classics for the rear. I took the car down to John at CCW and we(he really) did all the guess work. I am running Kuhmo Escta XS 295/35/17 tires which grip pretty good if you warm em up a touch. Once i get the car stanced right i will run the track out a touch via the lower conrol arms. I probably could have squeezed a 17x11 in there.

Here is is where i am hoping my ride height will be once I install my T3 camber plates.

Here is where it is now.

Got the intake fabbed up and finished, finally and also mounted the fender mirrors.

Installed new door seals, that was a pain... Ordered the AZC big brake kit with oversized rotors and 6 piston calipers and the 5 lug hubs. He said he doesn't recommend using the 13" on the 5 lug aluminum hubs because of the extra weight, so I went with the thicker 12.2" he has two different versions apparently.

Re: My RB26 240z Build

Nice update

Those rims are amazing, actually, everything looks amazing. Good job. Keep the updates coming.

Those rims are amazing, actually, everything looks amazing. Good job. Keep the updates coming.

-

boostedh23a1

- Posts: 281

- Joined: Tue Oct 17, 2006 1:37 pm

- Car: Datsun 240Z

Datsun 280Z - Location: Beaufort, SC

Re: My RB26 240z Build

Thanks, I would like to have gold wheels, but on since the car is yellow (for now) I didnt think that would look to great.

-

boostedh23a1

- Posts: 281

- Joined: Tue Oct 17, 2006 1:37 pm

- Car: Datsun 240Z

Datsun 280Z - Location: Beaufort, SC

Re: My RB26 240z Build

The CCWs in the rear are 17x10.5 with 6.5" BS. I dont know if these will work on anything other than the T3 R230 swap as I had to run the camber out all the way on the bottom of the hub. At full droop (limited by the axle), here is the inside clearance. Once I get the fenders cut, I hopefully will be able to lower it about an inch more. Once I set the ride height, I will run the track out on the lower control arms to fit the flares perfect. It's not a bad fit for how it is right off the get go though. I also installed ARP 100-7708 extended studs and Work RS-R extended lug nuts. To install you have to remove the hub.

Installed the T3 weld in camber plates. Man my ride quailty is 50-70% better than with modified oem hats, not really sure why, especially since the camber plates lower the car another inch or so. I did cut out a 1/4 thick rubber and install it between the top spring seat and the yellow camber bearing flange to help isolate some vibrations.

Have my Camery window regulators all finshed up and the fiberglass door shells installed. Due to the way I had to mount the drivers side motor, the shell will have a slight bulge in it. Cant wait to see them covered. I would love some Bride gias low max carbon kevlar seats in between these two, but given the price tag I do not see that as a viable option.

Installed the T3 weld in camber plates. Man my ride quailty is 50-70% better than with modified oem hats, not really sure why, especially since the camber plates lower the car another inch or so. I did cut out a 1/4 thick rubber and install it between the top spring seat and the yellow camber bearing flange to help isolate some vibrations.

Have my Camery window regulators all finshed up and the fiberglass door shells installed. Due to the way I had to mount the drivers side motor, the shell will have a slight bulge in it. Cant wait to see them covered. I would love some Bride gias low max carbon kevlar seats in between these two, but given the price tag I do not see that as a viable option.

-

boostedh23a1

- Posts: 281

- Joined: Tue Oct 17, 2006 1:37 pm

- Car: Datsun 240Z

Datsun 280Z - Location: Beaufort, SC

Re: My RB26 240z Build

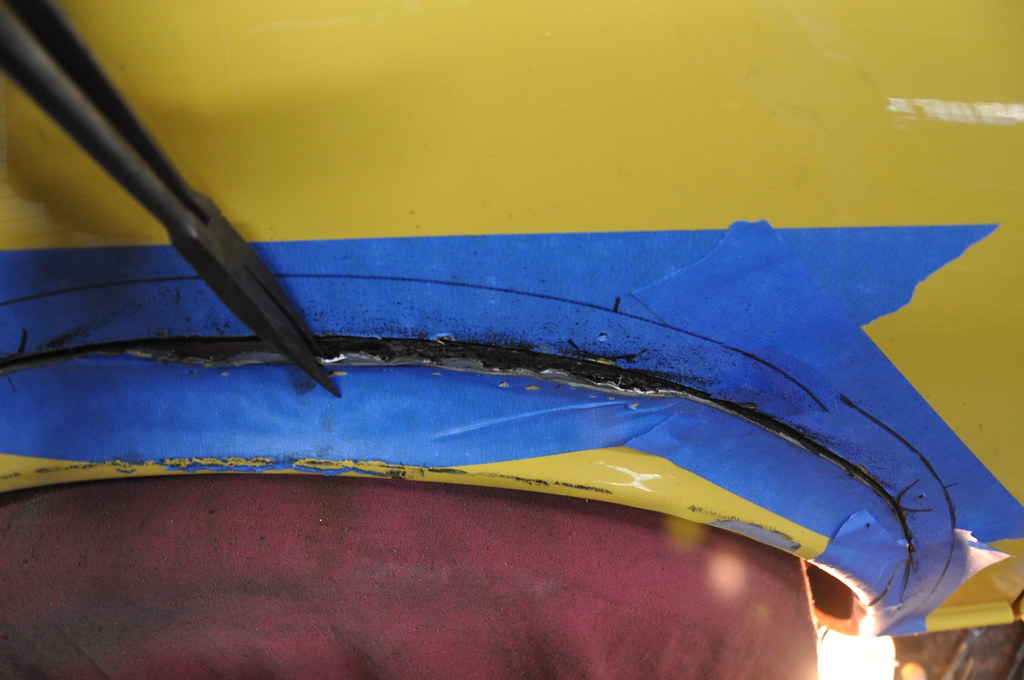

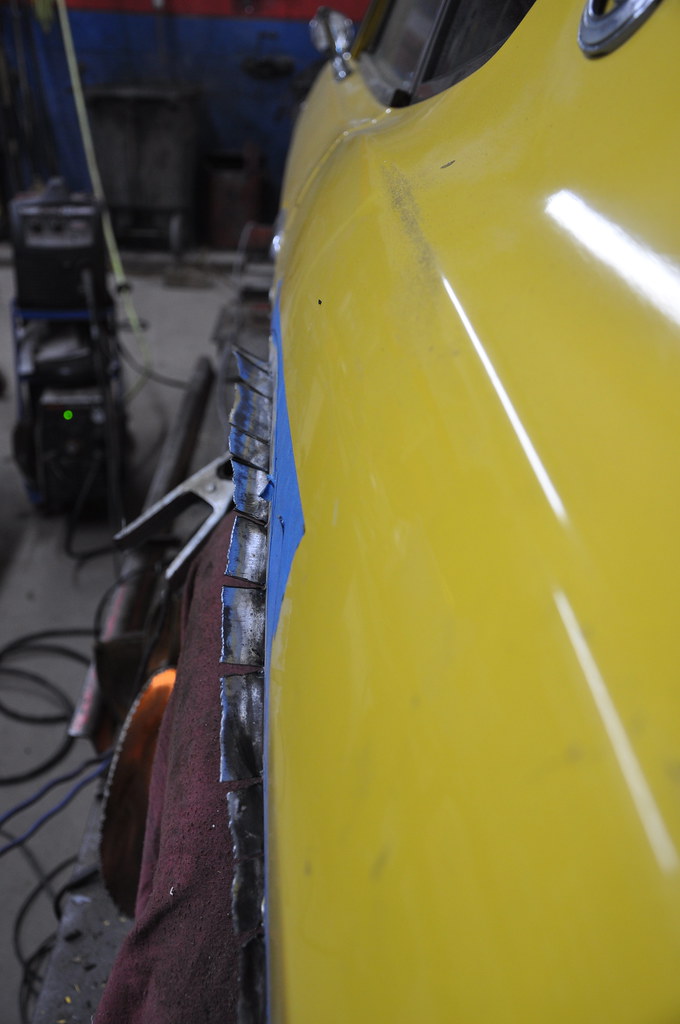

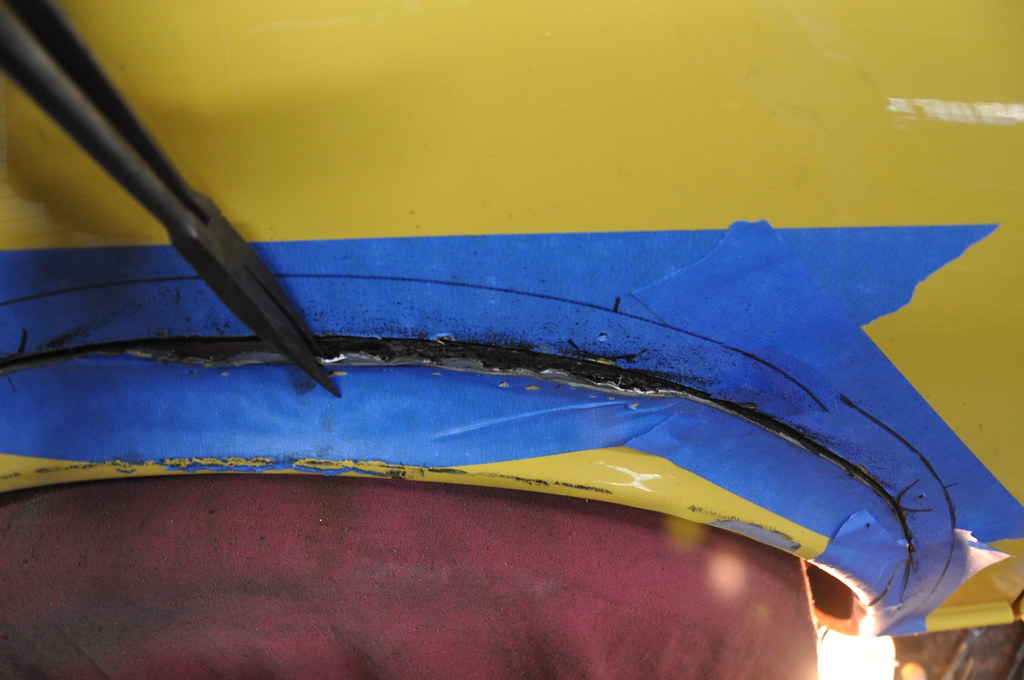

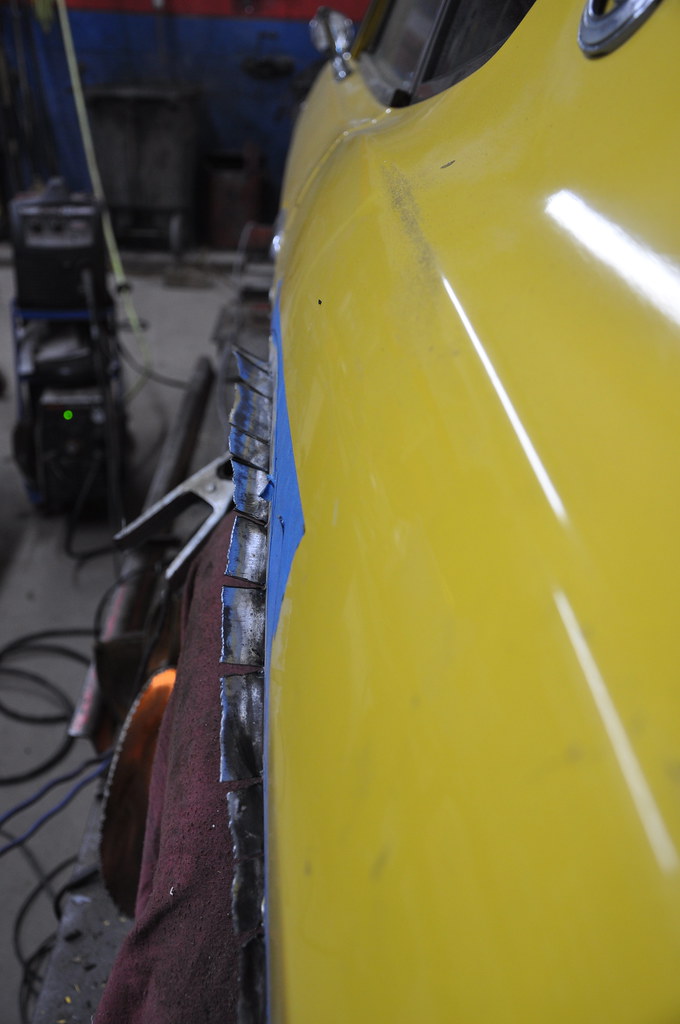

Well, I accomplished a lot this weekend. Got the rear fenders cut and done, for the most part. I left the lower ends unfinished incase i need to raise the flare some in order to run a lower ride height. Should have some bump stops coming in this week so maybe I can get figured out during the week. Anyway here are some pics.

Pics jump between passenger and drivers side but same concept...

Since I had my kelcos holding on my fenders i masked everything and traced my lines. The top of my flare is 3.75 up from the bottom of the oem fender.

Taped the fender and marked the top with a sharpie and came down 7/8" from there and made the lower mark. Before I cut anything i installed my blind nuts, i used metric 5mm but I would have used 6mm if my tool would do them. It will do aluminum 6mm but not steel. Anyway 5mm is plenty. I couldn't get 1 of them in there at full depth until I cut the fender. Putting them in before you cut helps to not bend the fender.

Next, cut the lower mark and begin pealing it down.

Should end up with something like this

Next, I cut little slits in the inner fender to let it conform easier. Slap it with a hammer (carefully, take your time) and the inner will meet the outer. Once its in place weld the BOTTOM side, just a tack were the outer fender meets the inner fender IN THE SLOTS YOU CUT. IF you were to weld it from the top when you go to bend the rest up (assuming you do as I have done) it will make it stick out to much, for my taste at least.

In this pic you can see where I am talking about tack welding it.

Now you have something like this.

Next, I took my plasma cutter and cut the tabs to about 3/8" long or so. Then i took a 5 pound sledge (used it as a dolly on the backside of the fender) and a ball-peen hammer and worked the lip up and over and welded it together. The Drivers side turned out a lot better than the passenger side one pictured, but the photo was better of the passenger side. Note that if you leave the tabs to long, when you bend them up they will be close to the top of your fender flare, you don't want this because when you weld it the heat will mess up your paint. I used my tig welder on pulse to keep the heat low but i guess a mig and a copper spoon would do too...

Here is the passenger side.

And the Drivers side, not finalized in this pic but you can see where its going.

Here is a pic of my blind nut tool.

Ok its time for beer and asprin.

Pics jump between passenger and drivers side but same concept...

Since I had my kelcos holding on my fenders i masked everything and traced my lines. The top of my flare is 3.75 up from the bottom of the oem fender.

Taped the fender and marked the top with a sharpie and came down 7/8" from there and made the lower mark. Before I cut anything i installed my blind nuts, i used metric 5mm but I would have used 6mm if my tool would do them. It will do aluminum 6mm but not steel. Anyway 5mm is plenty. I couldn't get 1 of them in there at full depth until I cut the fender. Putting them in before you cut helps to not bend the fender.

Next, cut the lower mark and begin pealing it down.

Should end up with something like this

Next, I cut little slits in the inner fender to let it conform easier. Slap it with a hammer (carefully, take your time) and the inner will meet the outer. Once its in place weld the BOTTOM side, just a tack were the outer fender meets the inner fender IN THE SLOTS YOU CUT. IF you were to weld it from the top when you go to bend the rest up (assuming you do as I have done) it will make it stick out to much, for my taste at least.

In this pic you can see where I am talking about tack welding it.

Now you have something like this.

Next, I took my plasma cutter and cut the tabs to about 3/8" long or so. Then i took a 5 pound sledge (used it as a dolly on the backside of the fender) and a ball-peen hammer and worked the lip up and over and welded it together. The Drivers side turned out a lot better than the passenger side one pictured, but the photo was better of the passenger side. Note that if you leave the tabs to long, when you bend them up they will be close to the top of your fender flare, you don't want this because when you weld it the heat will mess up your paint. I used my tig welder on pulse to keep the heat low but i guess a mig and a copper spoon would do too...

Here is the passenger side.

And the Drivers side, not finalized in this pic but you can see where its going.

Here is a pic of my blind nut tool.

Ok its time for beer and asprin.

-

boostedh23a1

- Posts: 281

- Joined: Tue Oct 17, 2006 1:37 pm

- Car: Datsun 240Z

Datsun 280Z - Location: Beaufort, SC

Re: My RB26 240z Build

Well, all Fed-Ex guys go to heaven in my story.

-

boostedh23a1

- Posts: 281

- Joined: Tue Oct 17, 2006 1:37 pm

- Car: Datsun 240Z

Datsun 280Z - Location: Beaufort, SC

Re: My RB26 240z Build

Out with the old and in with the new... I was expecting them to be really twitchy but they feel fine. Granted I haven't stabbed them yet, but normal street driving seems fine so far.