KA24DER Intercooler Questions

- superDorifto

- Posts: 1306

- Joined: Mon Jun 13, 2005 1:13 pm

- Car: 1997 Eclipse Spyder - AWD/5spd swap in progress

1995 Q45 - 5spd swap in progress

1984 200sx hatch(KA-t swap) - 355WHP

1991/1993/1995/1997 240s - Dead

1982 200sx hatch - fixed/scrapped - Location: CT

Re: KA24DER Intercooler Questions

MagikDragon just gave me a call and he feels up to the task of making the intake/heat exchanger. I'm gonna take a pass at rendering up something in Unigraphics after work tomorrow to get an understanding of the flat patter shapes that we'll need to seal off all of the runners.

I'll hopefully have some pics to post tomorrow.

I'll hopefully have some pics to post tomorrow.

- PapaSmurf2k3

- Site Admin

- Posts: 24075

- Joined: Thu Nov 21, 2002 3:20 pm

- Car: 2017 Corvette, 2018 Focus ST, 1993 240sx truck KA Turbo.

- Location: Merrimack, NH

- superDorifto

- Posts: 1306

- Joined: Mon Jun 13, 2005 1:13 pm

- Car: 1997 Eclipse Spyder - AWD/5spd swap in progress

1995 Q45 - 5spd swap in progress

1984 200sx hatch(KA-t swap) - 355WHP

1991/1993/1995/1997 240s - Dead

1982 200sx hatch - fixed/scrapped - Location: CT

Re: KA24DER Intercooler Questions

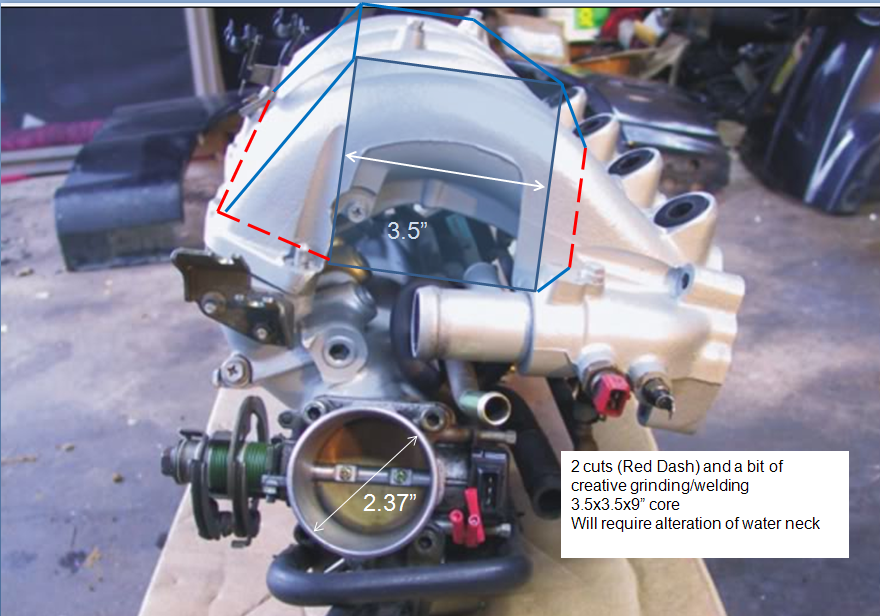

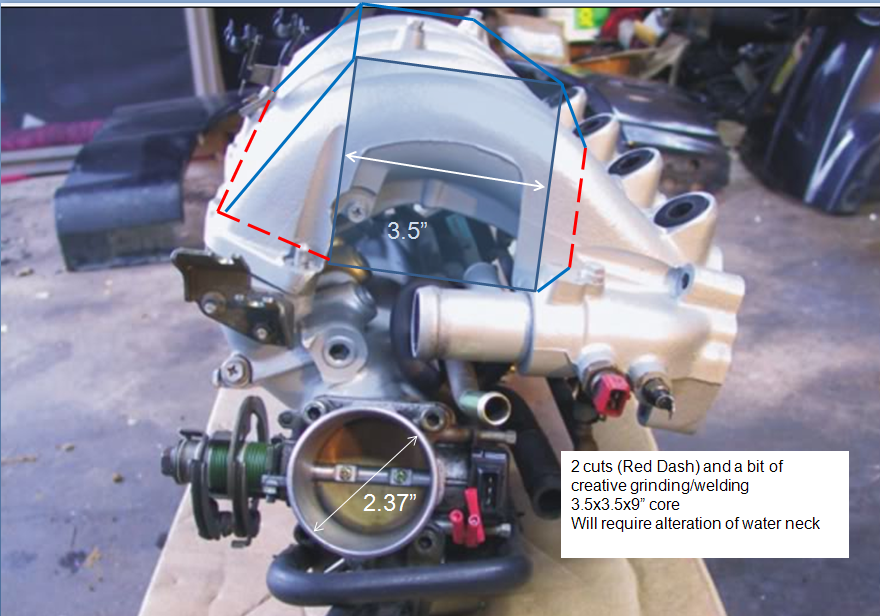

Granted this pic is a little crude...but hey, it was a busy day and this was all I could crank out on my lunch break.

This is entirely based off what google spit out for a stock throttle body dia for a KA was...without actually measuring anything, I just wanted to get a better idea if the core would even fit.

I'm going to take actual measurements when I get home, but I think its pretty clear that the 3.5 core will just barely fit. The water neck is going to need to change, and the large piece of webbing that is left over from the casting will need to go as well. Ill be able to work out exactly what modifications will be needed at the water neck once I have actual measurements.

Using a couple other online calculators, at max boost, 14 psi, 100deg day, I keep coming back with a ~550cfm at 7000 rpms out of the M62, right on the hair edge of what this size cooler can handle. Planning to run water glycol mix with a big radiator and fan to keep the water temp as low as possible.

I know Moso wants to bump up to the 4.5" core, but At that point using any part of the stock manifold really goes out the window.

for simplicities sake I am not concerned with the dimensions of the "in" plenum, most charge coolers are IMMEDIATELY after the compressor exit, and do not have runners, or stacks or any fancy aero trickery before the charge enters the core. On the exit side I'm thinking a plate with radiused edges on the entry to each runner similar to the KA24DER kit. That plate can be welded on first, making it easier to seal up the rest of the plenum.

This is entirely based off what google spit out for a stock throttle body dia for a KA was...without actually measuring anything, I just wanted to get a better idea if the core would even fit.

I'm going to take actual measurements when I get home, but I think its pretty clear that the 3.5 core will just barely fit. The water neck is going to need to change, and the large piece of webbing that is left over from the casting will need to go as well. Ill be able to work out exactly what modifications will be needed at the water neck once I have actual measurements.

Using a couple other online calculators, at max boost, 14 psi, 100deg day, I keep coming back with a ~550cfm at 7000 rpms out of the M62, right on the hair edge of what this size cooler can handle. Planning to run water glycol mix with a big radiator and fan to keep the water temp as low as possible.

I know Moso wants to bump up to the 4.5" core, but At that point using any part of the stock manifold really goes out the window.

for simplicities sake I am not concerned with the dimensions of the "in" plenum, most charge coolers are IMMEDIATELY after the compressor exit, and do not have runners, or stacks or any fancy aero trickery before the charge enters the core. On the exit side I'm thinking a plate with radiused edges on the entry to each runner similar to the KA24DER kit. That plate can be welded on first, making it easier to seal up the rest of the plenum.

- superDorifto

- Posts: 1306

- Joined: Mon Jun 13, 2005 1:13 pm

- Car: 1997 Eclipse Spyder - AWD/5spd swap in progress

1995 Q45 - 5spd swap in progress

1984 200sx hatch(KA-t swap) - 355WHP

1991/1993/1995/1997 240s - Dead

1982 200sx hatch - fixed/scrapped - Location: CT

Re: KA24DER Intercooler Questions

Well...just bit the bullet, ordered the air to water core, and all the alluminum sheet and plate that I "think" I'll need. Sean is on board to weld it up, so hopefully I'll have some build pics to post in a few weeks.

KA-R Charge Cooler FTW!!!

KA-R Charge Cooler FTW!!!

- superDorifto

- Posts: 1306

- Joined: Mon Jun 13, 2005 1:13 pm

- Car: 1997 Eclipse Spyder - AWD/5spd swap in progress

1995 Q45 - 5spd swap in progress

1984 200sx hatch(KA-t swap) - 355WHP

1991/1993/1995/1997 240s - Dead

1982 200sx hatch - fixed/scrapped - Location: CT

Re: KA24DER Intercooler Questions

I LOVE getting shiny new parts in the mail. THis week has felt like Christmas in June, and I am way behind on updating my build thread, but this intake is taking up so much of my attention that I want to get it squared away before I lose interest...

Pics of the cooler for size reference, sorry about the washed out colors, but a camera phone will have to do with the money I am spending on this car.

And the final one for today, ever see that M&M commercial were they talk about stuffing the pretzel inside...the intercooler and my spare intake are having that very discussion right now...

Hopefully with the long weekend I can get everything mocked up...pics will follow either way.

Pics of the cooler for size reference, sorry about the washed out colors, but a camera phone will have to do with the money I am spending on this car.

And the final one for today, ever see that M&M commercial were they talk about stuffing the pretzel inside...the intercooler and my spare intake are having that very discussion right now...

Hopefully with the long weekend I can get everything mocked up...pics will follow either way.

-

Nismo_Freak

- Posts: 11665

- Joined: Wed Jul 24, 2002 10:42 pm

- Car: 89 240SX

Re: KA24DER Intercooler Questions

I would simplify it by remote mounting the blower and routing the blower outlet to the OEM intercooler location on a CA / SR car where you can install the heat exchanger. Then you can run the piping back through the OEM routing and not have to mess with the IACV / manifold / etc. A roots blower is not going to have any trouble charging a couple feet of charge piping, and you'll see better cooling in the charge temps and in both coolant sources.

- superDorifto

- Posts: 1306

- Joined: Mon Jun 13, 2005 1:13 pm

- Car: 1997 Eclipse Spyder - AWD/5spd swap in progress

1995 Q45 - 5spd swap in progress

1984 200sx hatch(KA-t swap) - 355WHP

1991/1993/1995/1997 240s - Dead

1982 200sx hatch - fixed/scrapped - Location: CT

Re: KA24DER Intercooler Questions

Remote mount will most likey be the works in the future at some point. I've studied every supercharged KA dyno chart that I can find, and if the motor behaves the way I think it will, an M90 will find its way into the engine bay. Remote mounting the M62 just doesn't make much sense to me.

Just looking to add some redundancy by ensuring that my cooling system can't fail be me forgetting to fill it up.

It not like I'm expecting to gain a rediculous amount of power with the charge cooler, but if it helps keep temps anywhere as low as a meth kit would I would consider this little experiment a success.

I don't have any pics, but I was able to make the welding jig for the manifold today, hopefully I can find some time to section the manifold tomorrow,

Just looking to add some redundancy by ensuring that my cooling system can't fail be me forgetting to fill it up.

It not like I'm expecting to gain a rediculous amount of power with the charge cooler, but if it helps keep temps anywhere as low as a meth kit would I would consider this little experiment a success.

I don't have any pics, but I was able to make the welding jig for the manifold today, hopefully I can find some time to section the manifold tomorrow,

Re: KA24DER Intercooler Questions

I am really interested in how this turns out, cant wait for more pics.

-

Nismo_Freak

- Posts: 11665

- Joined: Wed Jul 24, 2002 10:42 pm

- Car: 89 240SX

Re: KA24DER Intercooler Questions

Intercooling a roots blower will yield quite a bit. The density increase will push pressure back up, so you'll see less boost drop. DeltaP is the name of the game until you start to exceed 0.3 Mach in the intake path, then it's better to seek velocity decrease and density gains.superDorifto wrote: It not like I'm expecting to gain a rediculous amount of power with the charge cooler, but if it helps keep temps anywhere as low as a meth kit would I would consider this little experiment a success.

I don't have any pics, but I was able to make the welding jig for the manifold today, hopefully I can find some time to section the manifold tomorrow,

- superDorifto

- Posts: 1306

- Joined: Mon Jun 13, 2005 1:13 pm

- Car: 1997 Eclipse Spyder - AWD/5spd swap in progress

1995 Q45 - 5spd swap in progress

1984 200sx hatch(KA-t swap) - 355WHP

1991/1993/1995/1997 240s - Dead

1982 200sx hatch - fixed/scrapped - Location: CT

Re: KA24DER Intercooler Questions

LOL engineer speak...so the delta P is really driven by the fact the the air to water coolers are so damn efficient? I'll be honest, I can't remember anything from my thermo classes other than power cycle calculations for silly things like ideal power plants and turbines. And I've searched for topics and discussions in other forums about charge cooler design and plenum design but have come up empty...

My main concern is keeping the flow through the core as laminar as possible, and not creating a series of plenums that drive pressure variations across the cylinders.

As it is the charge exiting the screws is well above .3 Mach, it hits the wall at the far corner of the blower, changes direction, fills the plenum under the plate...fills the space in the runners, and waits patiently for a valve to open. I am adding 2 additional plenums, and potentially diverting/recombining the charge as it exits the cooler.

I'm hoping the having 1/2 and 3/4 grouped together either with seperate plenums, or with baffling will minimize any pressure variations because of the alternating intake events. I'm thinking that each "side" of the plenum will have enough time to stabalize to a consistent charge to each cyl.

I would hate to have 2 cylinders run rich, and 2 constantly running lean.

As far as a velocity gain, the only place to even think about puting a venturi or a restriction would be after the cooler its self. accelerating the charge through the cooler would lower the efficiency of the cooler. either way this thing eats up 8-9 inches of runner length along the spline of each runner. That venturi would be right before the fuel injector....

It is something to think about tho..

My main concern is keeping the flow through the core as laminar as possible, and not creating a series of plenums that drive pressure variations across the cylinders.

As it is the charge exiting the screws is well above .3 Mach, it hits the wall at the far corner of the blower, changes direction, fills the plenum under the plate...fills the space in the runners, and waits patiently for a valve to open. I am adding 2 additional plenums, and potentially diverting/recombining the charge as it exits the cooler.

I'm hoping the having 1/2 and 3/4 grouped together either with seperate plenums, or with baffling will minimize any pressure variations because of the alternating intake events. I'm thinking that each "side" of the plenum will have enough time to stabalize to a consistent charge to each cyl.

I would hate to have 2 cylinders run rich, and 2 constantly running lean.

As far as a velocity gain, the only place to even think about puting a venturi or a restriction would be after the cooler its self. accelerating the charge through the cooler would lower the efficiency of the cooler. either way this thing eats up 8-9 inches of runner length along the spline of each runner. That venturi would be right before the fuel injector....

It is something to think about tho..

-

Nismo_Freak

- Posts: 11665

- Joined: Wed Jul 24, 2002 10:42 pm

- Car: 89 240SX

Re: KA24DER Intercooler Questions

They are efficient because they shed heat faster due to the proximity of water to the exchanger surface and the thermal capacitance of water itself, and because of that efficiency they are physically smaller which takes less time to fill, etc.superDorifto wrote:LOL engineer speak...so the delta P is really driven by the fact the the air to water coolers are so damn efficient? I'll be honest, I can't remember anything from my thermo classes other than power cycle calculations for silly things like ideal power plants and turbines. And I've searched for topics and discussions in other forums about charge cooler design and plenum design but have come up empty.

Laminar doesn't exist in all those bends, through the compressor, etc. The flow is massively turbulent and will eddy at every bend. The diffusion angle of the cooler itself is going to cause separation. From a micro level the flow is constantly being pulled and reflected due to helmholtz resonance and the general elasticity of the air. The idea is to minimize loss, gain density, and see what happens.superDorifto wrote:My main concern is keeping the flow through the core as laminar as possible, and not creating a series of plenums that drive pressure variations across the cylinders.

The air is compressed due to the diffusion of the velocity, so yes, it will achieve well over Mach at one given point. Turbochargers spin up around 150 - 300K RPM and the velocity vector is incredibly high. That's why they have the A/R scroll housing to diffuse the velocity into pressure. A roots blower relies a bit more on it's shear size and brute force to cram air into the engine, and that's why they are less efficient apart from using direct engine power to turn a gearbox or drive screw.superDorifto wrote: As it is the charge exiting the screws is well above .3 Mach, it hits the wall at the far corner of the blower, changes direction, fills the plenum under the plate...fills the space in the runners, and waits patiently for a valve to open. I am adding 2 additional plenums, and potentially diverting/recombining the charge as it exits the cooler.

When BMW engineers have told me that they simply can only guess at the fluid dynamics within an airbox I assume that means we have no possible chance in hell of really gauging what is going to work apart from trial and error. The OEM manifold on the engine is specified to deliver a VE boost at a particular RPM window, and in the case of extremely high revving engines, they can have two moments of increased VE due to 2nd and 3rd level harmonics.superDorifto wrote: I'm hoping the having 1/2 and 3/4 grouped together either with seperate plenums, or with baffling will minimize any pressure variations because of the alternating intake events. I'm thinking that each "side" of the plenum will have enough time to stabalize to a consistent charge to each cyl.

I would run a single plenum unless you are going to run management that allows you to trim individual cylinders. It's more simplistic and quite honestly you're going to have to link near firing cylinders on the floor of the plenum to really seek a benefit from resonance tuning. Look at the airbox and horn designs on F1 engines, they will often share two cylinders to allow the wake to spill over into the neighboring cylinder and promote a higher chance of a high pressure or moderate pressure moment prior to the valve opening.

Plot significant lift moment as a function of a specific RPM for all 4-cyls with crank degrees expressed on the X-axis. It'll expose where you need to theoretically shift the runner length and plenum volume, but theoretical is just theoretical, it still involves alot of testing and theory rework.

I don't think you are going to have that problem.superDorifto wrote:I would hate to have 2 cylinders run rich, and 2 constantly running lean.

I'd just avoid all of that and stick with simplicity. Control what you can realistically and simplistically control.superDorifto wrote: As far as a velocity gain, the only place to even think about puting a venturi or a restriction would be after the cooler its self. accelerating the charge through the cooler would lower the efficiency of the cooler. either way this thing eats up 8-9 inches of runner length along the spline of each runner. That venturi would be right before the fuel injector....

- superDorifto

- Posts: 1306

- Joined: Mon Jun 13, 2005 1:13 pm

- Car: 1997 Eclipse Spyder - AWD/5spd swap in progress

1995 Q45 - 5spd swap in progress

1984 200sx hatch(KA-t swap) - 355WHP

1991/1993/1995/1997 240s - Dead

1982 200sx hatch - fixed/scrapped - Location: CT

Re: KA24DER Intercooler Questions

Well, what I can gather from you post is...

1) you know vastly more about fluid dynamics than I do...

2) My hunch that the over efficiency of the cooler MAY potentially make up for any failure on my part to design anything close to an optimum manifold.

Looking at the cooler ant the intake again I think that shifting the cooler closer to the superchager adaptor plate may not be such a bad Idea, it sure as hell simplifies the fabrication, and keeps the whole design much simpler.

You're note about the designers at BMW strikes a chord...I have some friends that work at Pratt and Whitney, and for the most part their analysis of turbulent airflow through heat exchangers and ducted structures is based in large part on their own legacy positive/negative experiences...

Mostly because they can't model the system with enough fidelity to predict system efficiency accurately. A 2 or 3D CFD model will let them see where they potentially may have issues, but once the engine is running and up to speed all bets are off. They just design to the envelope points and build enough alter-ability into the system to ensure that the critical points of system functionality are met.

Basically they stick to what has worked well in the past... because it cost too much money to analyse a new system to ensure that it will meet requirements.

With so many unknowns in this set up, I'm thinking I should do the same...I mean that was the point from the beginning, but the simpler I can keep the in.out plenums, the higher likelihood that this cooler will actually do its job.

1) you know vastly more about fluid dynamics than I do...

2) My hunch that the over efficiency of the cooler MAY potentially make up for any failure on my part to design anything close to an optimum manifold.

Looking at the cooler ant the intake again I think that shifting the cooler closer to the superchager adaptor plate may not be such a bad Idea, it sure as hell simplifies the fabrication, and keeps the whole design much simpler.

You're note about the designers at BMW strikes a chord...I have some friends that work at Pratt and Whitney, and for the most part their analysis of turbulent airflow through heat exchangers and ducted structures is based in large part on their own legacy positive/negative experiences...

Mostly because they can't model the system with enough fidelity to predict system efficiency accurately. A 2 or 3D CFD model will let them see where they potentially may have issues, but once the engine is running and up to speed all bets are off. They just design to the envelope points and build enough alter-ability into the system to ensure that the critical points of system functionality are met.

Basically they stick to what has worked well in the past... because it cost too much money to analyse a new system to ensure that it will meet requirements.

With so many unknowns in this set up, I'm thinking I should do the same...I mean that was the point from the beginning, but the simpler I can keep the in.out plenums, the higher likelihood that this cooler will actually do its job.

- superDorifto

- Posts: 1306

- Joined: Mon Jun 13, 2005 1:13 pm

- Car: 1997 Eclipse Spyder - AWD/5spd swap in progress

1995 Q45 - 5spd swap in progress

1984 200sx hatch(KA-t swap) - 355WHP

1991/1993/1995/1997 240s - Dead

1982 200sx hatch - fixed/scrapped - Location: CT

Re: KA24DER Intercooler Questions

I was asking more because I have not finished my degree yet and haven't taken any heat transmission courses...But which is the driver? I know that the heat capacity of the water plays a huge role in the ability of the cooler to dissipate heat in greater quantities, and at a faster rate, but looking at the cores I wonder...Nismo_Freak wrote: They are efficient because they shed heat faster due to the proximity of water to the exchanger surface and the thermal capacitance of water itself, and because of that efficiency they are physically smaller which takes less time to fill, etc.

Is the resultant drop in temp/increase in density driving a large potion of the associated low pressure drop across the core that is inherent to air to water coolers? I know its a rhetorical sort of question, but I never thought of the driver for the delta P being the rate at which the core can suck heat away form the charge...That was my insight for the day at least.

-

Nismo_Freak

- Posts: 11665

- Joined: Wed Jul 24, 2002 10:42 pm

- Car: 89 240SX

Re: KA24DER Intercooler Questions

The faster the core can pull heat away from the air the greater the deltaT and the greater the deltaT the greater the uptick in density and pressure. Turbochargers can regulate pressure since they use pressure to dictate wastegate control. Superchargers don't have that luxury so aftercooling becomes a good way to "regain" some of the pressure. After all, it's pressure that feeds the motor, we want maximum pressure at the inlet valve when it opens so long as that pressure doesn't overaccelerate the air to the point that we're choking the port flow. You can tell a port is choked when you raise the boost pressure and the motor doesn't make much more power even though the compressor is still efficient; typically high in the RPM band since airflow needs to increase in velocity to feed the motor at higher RPM. From stupid testing the KA has some pretty decent design, so it's not really an issue until you start wanting BIG power.superDorifto wrote:I was asking more because I have not finished my degree yet and haven't taken any heat transmission courses...But which is the driver? I know that the heat capacity of the water plays a huge role in the ability of the cooler to dissipate heat in greater quantities, and at a faster rate, but looking at the cores I wonder...Nismo_Freak wrote: They are efficient because they shed heat faster due to the proximity of water to the exchanger surface and the thermal capacitance of water itself, and because of that efficiency they are physically smaller which takes less time to fill, etc.

Is the resultant drop in temp/increase in density driving a large potion of the associated low pressure drop across the core that is inherent to air to water coolers? I know its a rhetorical sort of question, but I never thought of the driver for the delta P being the rate at which the core can suck heat away form the charge...That was my insight for the day at least.

Pressure drop is a measure of the loss in flow due to the air / liquid passing through the exchanger. If you lose energy in the flow (inertia) then the pump has to work harder to maintain the same flow rate. The more efficient the heat exchanger the less it needs to impede the airflow to yield a "good enough" result. It's kinda a catch-22 ... if you make some massive and uber-effective heat exchanger that requires alot of energy to push the flow through it, the compressor (turbo) will accommodate that with a higher RPM, which makes more pressure and may push the turbo further out of it's efficiency range (FMIC on a T25 comes to mind) which just makes even more heat. End result is lower turbo bearing life, increased oil temps, less boost response, and a marginally better charge temp.

FWIW I always thought a roots blown KA would be awesome. Everyone that talked about it always came to the conclusion that an M90 would be better suited.

The REAL trick and expense is going to be to design a great header for the motor. A header done right would be the key in making this engine scream.

- WDRacing

- Moderator

- Posts: 23925

- Joined: Mon Nov 25, 2002 2:00 am

- Car: 95 240SX, 99 BMW 540i, 01 Chevy Express, 14 Ford Escape

- Location: MFFO

- Contact:

Re: KA24DER Intercooler Questions

The only reason he knows any of that is because I told him forever ago...

The M90 or better would be the best bet for the KA, especially if you run water/meth injection so you can really crank up the wick.

The M90 or better would be the best bet for the KA, especially if you run water/meth injection so you can really crank up the wick.

Re: KA24DER Intercooler Questions

ok please dont hang me for not knowing but...... I was planning on running the M90 on my kade remotely and running an inline heat exchanger. it was my intention to try to stay away from meth injection. is there still a need for meth if I have an exchanger?

- superDorifto

- Posts: 1306

- Joined: Mon Jun 13, 2005 1:13 pm

- Car: 1997 Eclipse Spyder - AWD/5spd swap in progress

1995 Q45 - 5spd swap in progress

1984 200sx hatch(KA-t swap) - 355WHP

1991/1993/1995/1997 240s - Dead

1982 200sx hatch - fixed/scrapped - Location: CT

Re: KA24DER Intercooler Questions

Per Nismo_Freak's comments....not if the cooler can effectively cool the charge and not serve as a restriction that causes the compressor(supercharger) to have to operate outside of its most efficient rpm range.

But the meth/water kit does act to increase the sealing between the spinning lobes of the screws, and has the added benefit of cooling them directly. Most people with meth set ups see 1-2 psi above the rated output for their supercharger because the liquid seals the microscopic gaps between the lobes.

I keep finding conflicting information about whether the methanol negatively impacts the Teflon coating on the lobes. Some say it helps, others say it doesn't matter.

I'm hoping that the cooler I'm running will let me run enough timing advance to make similar power to everyone else running meth.

But the meth/water kit does act to increase the sealing between the spinning lobes of the screws, and has the added benefit of cooling them directly. Most people with meth set ups see 1-2 psi above the rated output for their supercharger because the liquid seals the microscopic gaps between the lobes.

I keep finding conflicting information about whether the methanol negatively impacts the Teflon coating on the lobes. Some say it helps, others say it doesn't matter.

I'm hoping that the cooler I'm running will let me run enough timing advance to make similar power to everyone else running meth.

- superDorifto

- Posts: 1306

- Joined: Mon Jun 13, 2005 1:13 pm

- Car: 1997 Eclipse Spyder - AWD/5spd swap in progress

1995 Q45 - 5spd swap in progress

1984 200sx hatch(KA-t swap) - 355WHP

1991/1993/1995/1997 240s - Dead

1982 200sx hatch - fixed/scrapped - Location: CT

Re: KA24DER Intercooler Questions

Without knowing the velocity of the air moving through the plenum I guess I'm hanging the entire design on the assumption that the actual speed of the air is going to be sub Mach 0.3 as it exits the core. I was reading on another site, and for the life of me cannot remember where, that the discharge out of most of the M series blows is in excess of Mach 1 at sea level...at least immediately after the screws at full boost.Nismo_Freak wrote:After all, it's pressure that feeds the motor, we want maximum pressure at the inlet valve when it opens so long as that pressure doesn't overaccelerate the air to the point that we're choking the port flow.

With the contortions the air is going to have to make in the inner plenum, and traveling through the air to water core, I'm hoping that it slows down enough to not choke the efficiency of the blower...judging that others have used this supercharger with decent power to show for it, I'll hazard a guess that the velocity of the charge slows considerably in the inner plenum. I'm just adding another restriction in the flow path - hopefully the delta P efficiency of the cooler will balance out the velocity it robs from the charge.

Makes me wonder..

What are the chances that I a** ended my way into not only the right size cooler, but the right manifold design? I chose the core size based on max theoretical CFM that the KA could flow at red line, and am just hodge podging the intake together...

Hopefully my first foray into fabrication doesn't leave me mentally scared and broke, I would like ot tackle that project next...can you say equal length port matched header?Nismo_Freak wrote: The REAL trick and expense is going to be to design a great header for the motor. A header done right would be the key in making this engine scream.

Re: KA24DER Intercooler Questions

that was what i was hoping to hear. In the end i would like to do as little maintenance to the setup as possible, who likes to work on it when you could be driving it? that and the idea of loosing my motor to not refilling the meth reservoir is almost enough to make me sick in my hat. sorry if i didn't pick up that bit of info earlier, this thread has become a little hard to read, but the info here is killer. as far as the Teflon is concerned from what i understand on the older superchargers its fairly common (pre 97ish) on the newer ones they shouldn't loose any, meth or no meth. if you find yours is flaking you should periodically check the exchanger and make sure its not building up in there. as far as the loss in boost, most rebuilders remove the coating claiming that the loss in boost is negligible.

- superDorifto

- Posts: 1306

- Joined: Mon Jun 13, 2005 1:13 pm

- Car: 1997 Eclipse Spyder - AWD/5spd swap in progress

1995 Q45 - 5spd swap in progress

1984 200sx hatch(KA-t swap) - 355WHP

1991/1993/1995/1997 240s - Dead

1982 200sx hatch - fixed/scrapped - Location: CT

Re: KA24DER Intercooler Questions

Haha, we just need the one of the mods to include a warning in the title "warning: convoluted fluid dynamics discussion inside"

Have you picked an M90 up yet? I just spent like 30 min looking at ebay and have no idea what the differences are between the various GM models if there are any.

Have you picked an M90 up yet? I just spent like 30 min looking at ebay and have no idea what the differences are between the various GM models if there are any.

Re: KA24DER Intercooler Questions

not yet but i have spent a fair amount of time looking them up. be careful on ebay, most people have no idea what s/c they have. its best to first figure out which cars have the s/c you want and go from there. personally i would be looking for a gm charger from 98 to 03 from a gtp or s/c bonne. they all should be m90 with the new coating. there is also a guy on ebay who sells a plate that is machined to match the outport and mate it to a 2.5in tube.

-

Nismo_Freak

- Posts: 11665

- Joined: Wed Jul 24, 2002 10:42 pm

- Car: 89 240SX

Re: KA24DER Intercooler Questions

You're still full of s***.WDRacing wrote:The only reason he knows any of that is because I told him forever ago...

The M90 or better would be the best bet for the KA, especially if you run water/meth injection so you can really crank up the wick.

- superDorifto

- Posts: 1306

- Joined: Mon Jun 13, 2005 1:13 pm

- Car: 1997 Eclipse Spyder - AWD/5spd swap in progress

1995 Q45 - 5spd swap in progress

1984 200sx hatch(KA-t swap) - 355WHP

1991/1993/1995/1997 240s - Dead

1982 200sx hatch - fixed/scrapped - Location: CT

Re: KA24DER Intercooler Questions

why do I get the feeling that Moso and myself are serving to settle a bench racing argument between WD and Nismo????

-

Nismo_Freak

- Posts: 11665

- Joined: Wed Jul 24, 2002 10:42 pm

- Car: 89 240SX

Re: KA24DER Intercooler Questions

It's an old rivalry since I preferred the SR. That and his rampant homosexuality knows no bounds.superDorifto wrote:why do I get the feeling that Moso and myself are serving to settle a bench racing argument between WD and Nismo????

- superDorifto

- Posts: 1306

- Joined: Mon Jun 13, 2005 1:13 pm

- Car: 1997 Eclipse Spyder - AWD/5spd swap in progress

1995 Q45 - 5spd swap in progress

1984 200sx hatch(KA-t swap) - 355WHP

1991/1993/1995/1997 240s - Dead

1982 200sx hatch - fixed/scrapped - Location: CT

Re: KA24DER Intercooler Questions

Slight change of plans. I bought what I thought was a Thomas Knight kit, but the supercharger adaptor plate is def aluminum...not steel. Going to weld the cooler right to the plate. simplifies the manufacture, and it eliminates some of the funky angles that would have been needed to utilize the lower runner.

Wanted to get some fab work done this weekend, but I spent my only free day on Sunday sanding paint of a CF hood....all god damned day....and its still not done.

Plus the .080" aluminum sheets came in today. This weekend is gonna be exciting, unless I get sidetracked again.

Wanted to get some fab work done this weekend, but I spent my only free day on Sunday sanding paint of a CF hood....all god damned day....and its still not done.

Plus the .080" aluminum sheets came in today. This weekend is gonna be exciting, unless I get sidetracked again.

Re: KA24DER Intercooler Questions

that was my original design. you may not want to weld that cooler directly to the s/c adapter unless you intend to port the plate to match the exchanger, if for no other reason than to be able to inspect and clean the exchanger.

- superDorifto

- Posts: 1306

- Joined: Mon Jun 13, 2005 1:13 pm

- Car: 1997 Eclipse Spyder - AWD/5spd swap in progress

1995 Q45 - 5spd swap in progress

1984 200sx hatch(KA-t swap) - 355WHP

1991/1993/1995/1997 240s - Dead

1982 200sx hatch - fixed/scrapped - Location: CT

Re: KA24DER Intercooler Questions

I have enough .250" plate stock to make a bolted flange at the "out" plenum interface with the manifold. The SC adaptor plate and the HEX core would be welded as one peice, and would allow for inspection/access to the core should the need arise.

Doing it this way will let me extend the volume/shape of the plenum and give it a proper profile without worrying about being crammed in between the runners...

Doing it this way will let me extend the volume/shape of the plenum and give it a proper profile without worrying about being crammed in between the runners...

Re: KA24DER Intercooler Questions

Im not sure im picking up what your putting down but none the less my worry would be flaking teflon from the s/c clogging the HEX on the s/c side and being unable to clean it out properly ( or really any foreign debris ). porting the s/c adapter plate to match the inlet port on the HEX would solve this problem if your dead set on welding the HEX to the S/C adapter plate. if we are saying the same thing, my bad.

- superDorifto

- Posts: 1306

- Joined: Mon Jun 13, 2005 1:13 pm

- Car: 1997 Eclipse Spyder - AWD/5spd swap in progress

1995 Q45 - 5spd swap in progress

1984 200sx hatch(KA-t swap) - 355WHP

1991/1993/1995/1997 240s - Dead

1982 200sx hatch - fixed/scrapped - Location: CT

Re: KA24DER Intercooler Questions

I'm basicly moving the bolted interface between the SC plate, and the upper intake manifold until after the intercooler. It'll be a b**** to unbolt while the manifold is in car, but it'll be possible.

I have a crude scetch that I'll post later tonight when I get home.

I have a crude scetch that I'll post later tonight when I get home.

- klattr1

- Posts: 1130

- Joined: Sat Sep 28, 2002 1:18 pm

- Car: GT42R powered S14/KA

- Location: Charlotte, NC

- Contact:

Re: KA24DER Intercooler Questions

I like the dialogue going on in this thread. I haven't seen words like laminar, turbulence, etc on Nissan car forums in a while : )

Since I'm the manufacturer of the KA24DER.com kits, I know the technical hurdles of what you're trying to go through cramming a heat exchanger in between the blower outlet and the runners. The packaging is already tight and you need a decent size core in order to effectively cool down the air coming out of the Eaton roots blower (which are known for 150+deg. F delta T depending on boost/speed).

I was going to build an inline intercooler upgrade for the KA24DER.com kits but with the added cost, it wouldn't be affordable enough for 240sx owners. But during my research I compared pros/cons of using traditional air-to-water inline cores, laminova cores and air-to-air setups. No matter which route I wanted to go, the engineering was going to be tough and the cost high (especially for the fluid based systems which would need a secondary heat exchanger and fluid pump+reservoir). The fluid systems would also be better off with a different CNC'ed plate that goes from 1-4 (outlet-to-core-to-four runners) instead of 1-4-1-4 to eliminate potential turbulence issues. Another thing to consider is by adding an inline intercooler sandwiched between the blower and head – it would lessen intake runner length which could affect the low to mid-range powerband of the car (which is the whole reason for going the blower route).

Have you considered using one of Xcessive's cast upper runners/manifolds to build from? Rich has the specs for the footprint of this online and you could easily waterjet/CNC a flange to match/adapt to.

http://www.xcessivemanufacturing.com/on ... =82&step=4

The last KA24DER setup I tuned was at 255 whp/249 ft.lbs at 10 psi. I try to educate people about these supercharger kits because most 240sx/KA24 owners are only familiar with or are told to run turbo kits. I daily drove my KA24DER powered S14 for over 1.5 yrs and it was definitely more fun than any sub 350whp 240sx setup I've ever experienced. Engine response is great and feels like you have a small V8 in the car.

Since I'm the manufacturer of the KA24DER.com kits, I know the technical hurdles of what you're trying to go through cramming a heat exchanger in between the blower outlet and the runners. The packaging is already tight and you need a decent size core in order to effectively cool down the air coming out of the Eaton roots blower (which are known for 150+deg. F delta T depending on boost/speed).

I was going to build an inline intercooler upgrade for the KA24DER.com kits but with the added cost, it wouldn't be affordable enough for 240sx owners. But during my research I compared pros/cons of using traditional air-to-water inline cores, laminova cores and air-to-air setups. No matter which route I wanted to go, the engineering was going to be tough and the cost high (especially for the fluid based systems which would need a secondary heat exchanger and fluid pump+reservoir). The fluid systems would also be better off with a different CNC'ed plate that goes from 1-4 (outlet-to-core-to-four runners) instead of 1-4-1-4 to eliminate potential turbulence issues. Another thing to consider is by adding an inline intercooler sandwiched between the blower and head – it would lessen intake runner length which could affect the low to mid-range powerband of the car (which is the whole reason for going the blower route).

Have you considered using one of Xcessive's cast upper runners/manifolds to build from? Rich has the specs for the footprint of this online and you could easily waterjet/CNC a flange to match/adapt to.

http://www.xcessivemanufacturing.com/on ... =82&step=4

The last KA24DER setup I tuned was at 255 whp/249 ft.lbs at 10 psi. I try to educate people about these supercharger kits because most 240sx/KA24 owners are only familiar with or are told to run turbo kits. I daily drove my KA24DER powered S14 for over 1.5 yrs and it was definitely more fun than any sub 350whp 240sx setup I've ever experienced. Engine response is great and feels like you have a small V8 in the car.