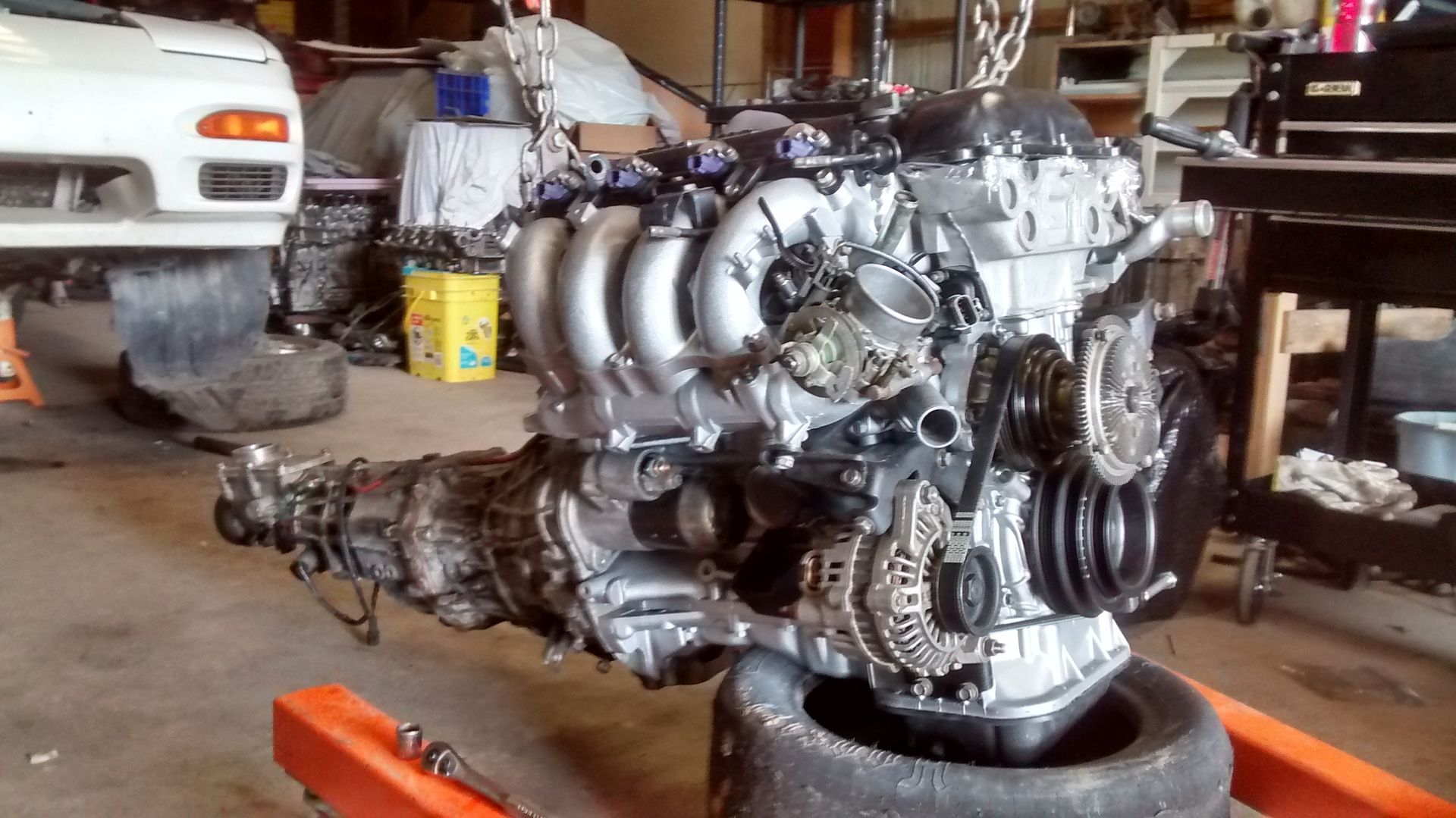

If you look closely at the last picture in my previous post, you should see three S13 SR20's. The one on the stand with the black cover is supposed to be a good running engine. I got it from a local-ish drifter who was having idle issues and smoking issues. He said the smoke was from the turbo and the idle issues were ignition/fuel. It's got ARP head studs, Crower springs and retainers, and a metal head gasket. When we pulled it out of his car, we discovered two of the injectors had broken connectors - we suspected this was causing the idle issues. This is the engine that I'm planning on dropping into the vert.

The second SR with the red cover is what was originally in my gold S14 when I bought it. This engine was oil starved. The previous owner had some podunk quick lube place do an oil change on his S14 with an S13 SR swap and they put the wrong oil filter on it. Hard to believe, right? It backed off the engine and the rest is history. It is a completely stock engine and the plan was to scavenge parts from this engine for the engine going into the vert.

Finally, the third SR in the very back has a blue-green cover. I picked this one up from another local-ish drifter. That engine had forged internals, a knife-edged crank, big cams, BC springs, ARPs, and a metal gasket. The previous owner thought he blew a piston due to lean conditions under boost. It was all ready 87mm, so saving the block would require more money and effort than either he or I would be interested in investing into it. I figured I'd use the parts from this engine to build myself a race engine for my S14.

You're probably wondering why you should care about all that. It will be evident as this post unfolds.

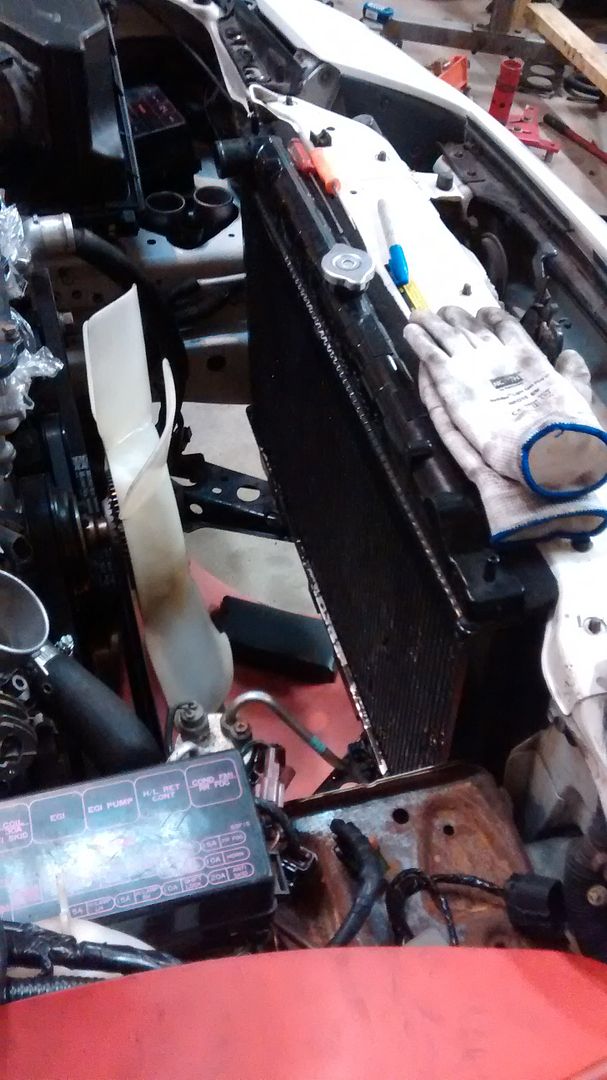

Now that the car is practically ready for the engine to go in, I started prepping the SR. At some point, I decided to peek down the ports to see how the valves looked. I'm certainly glad I did because the last valve on the exhaust side was wet. This usually means a leaking valve stem seal. This was either the cause of the smoking or contributing to it. Either way, I was going to have to do valve stem seals. For some reason, I decided I would just take the head off and have it done at my local machine shop. When I lifted the head, I wasn't really excited about what I was seeing.

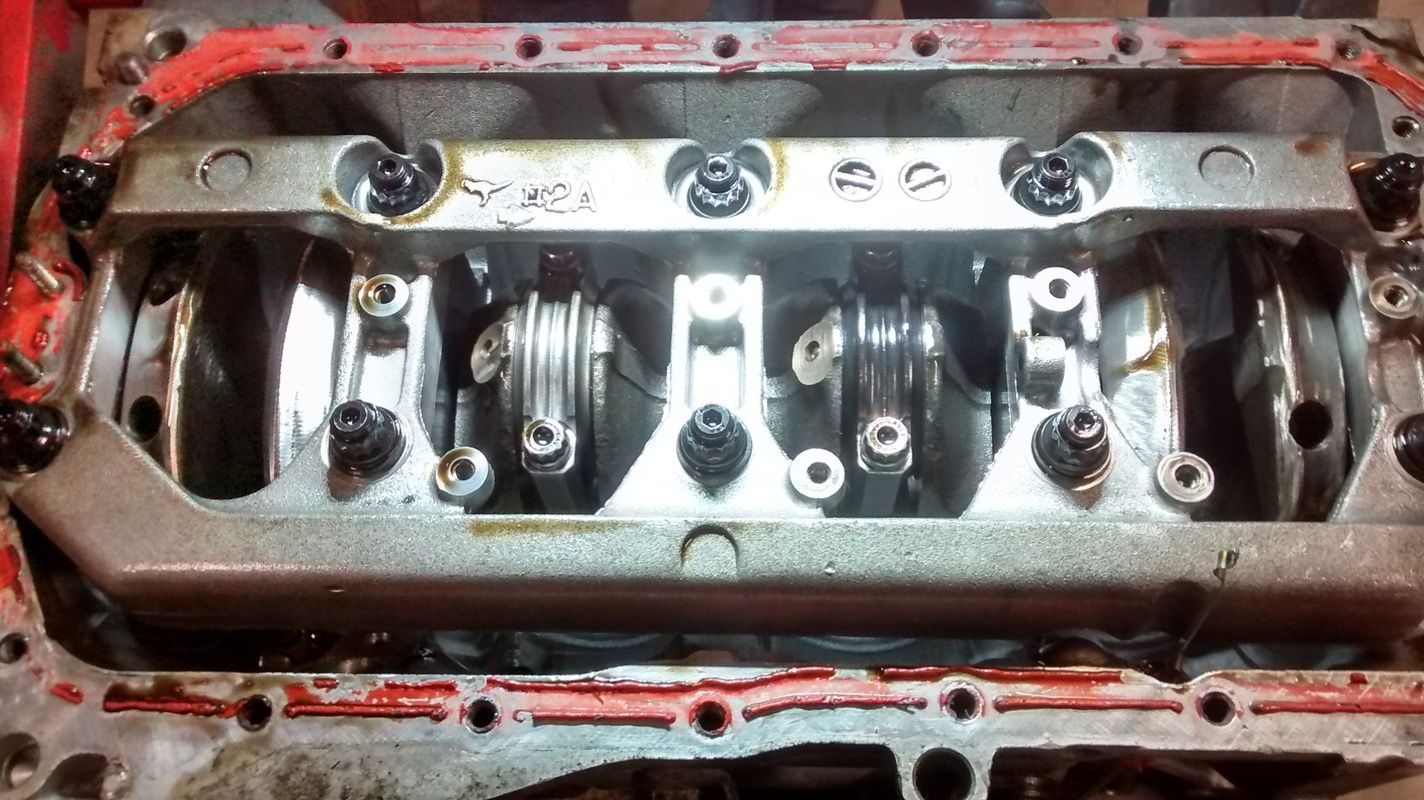

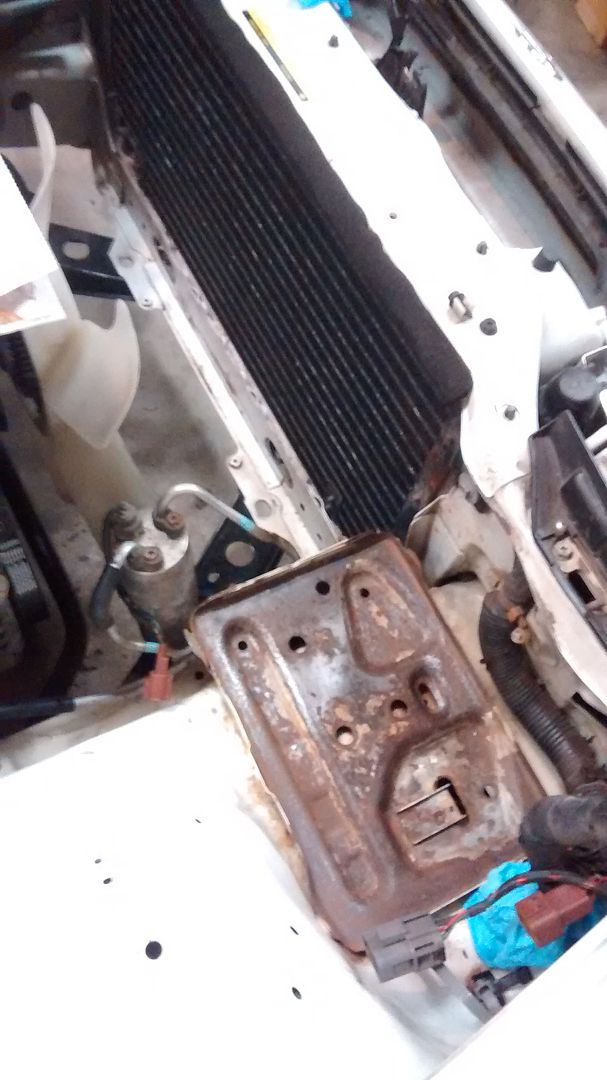

The further I got into this thing, the more issues turned up. The mating surface on the head was rough. The headgasket had been copper sprayed. Who does that with a metal headgasket? Probably someone cutting corners because they didn't want to do a proper resurface. When I tried to pull the HG off, it wouldn't come up. At some point, someone had cut the bottom layer of the gasket at the front cover - most likely for replacing the cover with the head still on. Well, they sandwiched the edges between the cover and the block, so now I've got to get further into this thing. It wasn't until after I had pulled the oil pans and front cover until I noticed some scouring in the #1 cylinder. Then after turning the crank, the #3 cylinder too.

So we're not using this engine... Time to find another block, I guess. I have an extra S14 block in the shop... I pulled it out and gave it a look over. I discovered some melted piston on cylinder #2. I took it to the machine shop to see if they could clean it up and maybe use this one. They hit it with some muriatic acid and a bearing scraper. No dice - that one needs an over bore. So I need to find another block again. Maybe... Let's check the forged engine first.

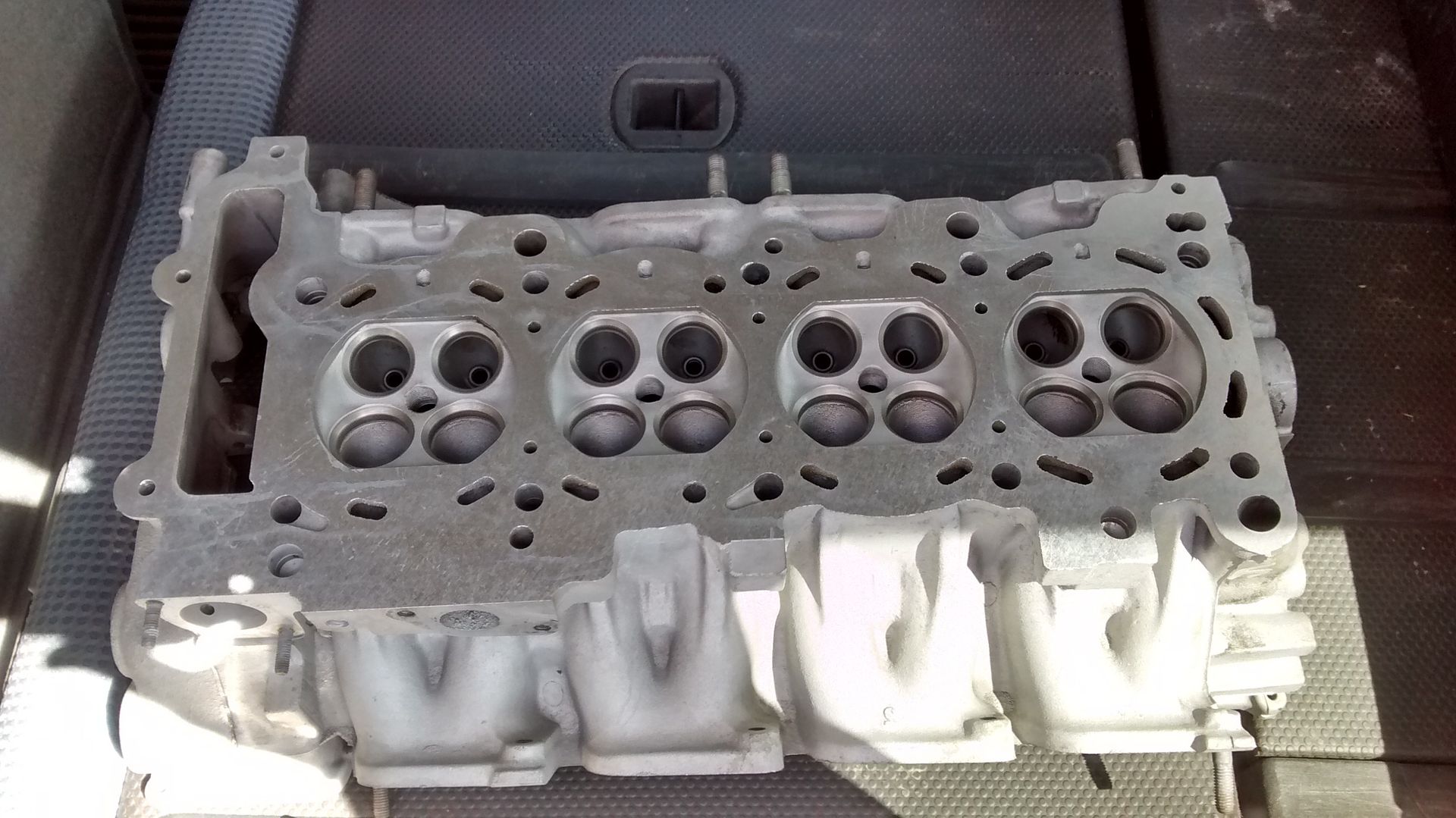

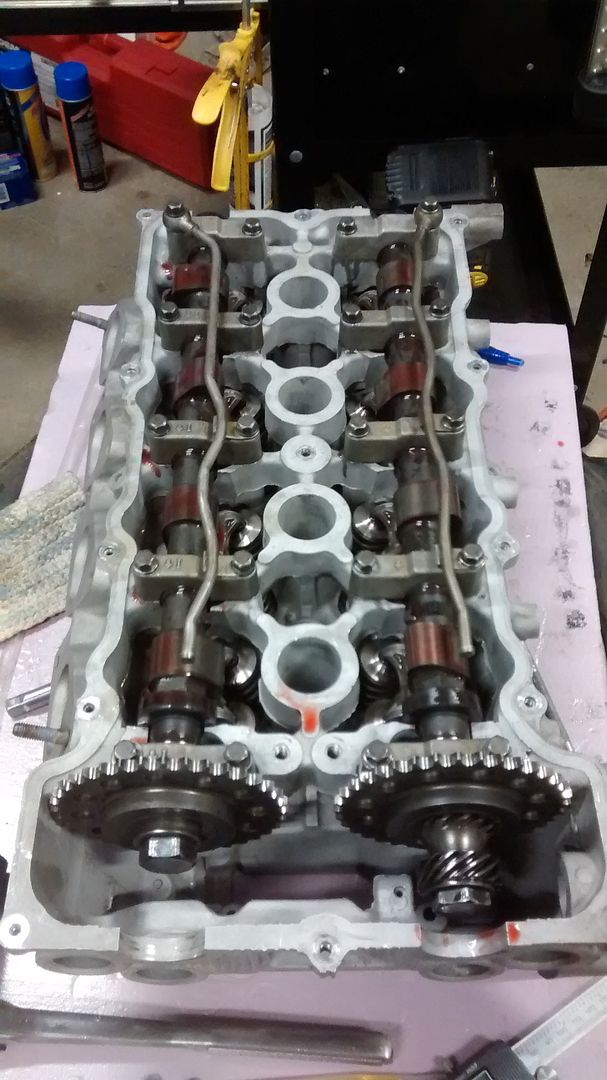

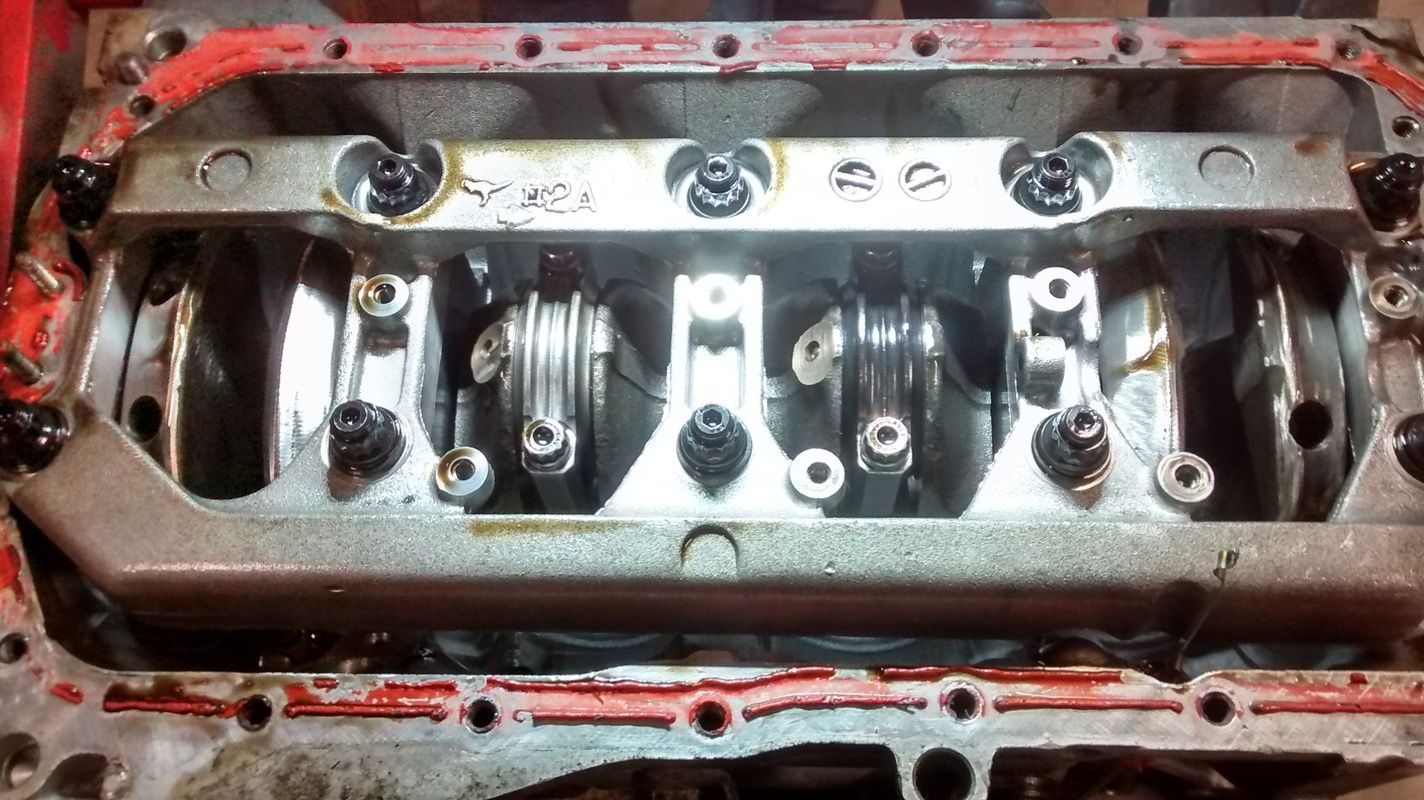

Everything in this engine was super clean. It must not have had very many miles on it since the last build. The cams are Brian Crower. I ran the numbers on them to discover they're 272 cams for an S14 SR. This car must have had terrible idle because the S14 intake cam is some 20 degrees different than the S13 cams because of the VCT. These are way more aggressive than I'd want to run in my S14 though. I peered down the ports of this one to discover four bad valve stem seals also - that explains the smoke in this one too.

After I lifted the head and inspected the pistons, I didn't see any evidence of detonation. The cylinder walls looked pretty good too. There was some wear, but I hoped it might clean up and seal with a hone and some fresh rings. The head surface looked really good too.

After I pulled the oil pans and front cover, I flipped it over to find what was really wrong with this engine.

Can you see it? The #2 connecting rod cap is black. It had a spun bearing.

Also, that's not a knife-edged crank. So I loaded up the block and internals and took them to the machine shop to discuss a new plan. The professionals told me that even with a hone and new rings,this was probably going to smoke a bit because it just won't seal. The #2 piston was junk as was that connecting rod and the crankshaft. So much for that plan. We decided to get the rods and pistons weighed so I could order replacement parts. I needed to call Wiseco and see what kind of specs they had on clyinder wall clearance in hopes that maybe we could find some wiggle room.

Turns out, there isn't enough wiggle room. They can get me a weight-matched replacement, but they're clearances are built in and you're just supposed to punch the blocks to the given bore size. You can take 0.001" - 0.004" out for boosted and racing applications, but we agreed that this wasn't going to be a good idea for this mostly street-driven car. So the block came back home.

Now that I'm looking at machine work, I might as well tear that first block down the rest of the way and take it in since it's still an 86mm block. We can put the Wiseco pistons in that block with some stock rods and that would make a pretty good street setup. Back on the engine stand it went. However, it continued to follow the trend of the deeper I got, the worse it became. This engine spun rod bearing #3. I also discovered after I pulled the crank that it had spun main bearing #3 also. The rest of the bearings had taken a significant beating in this engine too.

At this point, it's looking like I'll need to add an align bore to this block as well as the cylinder re-bores. I've got another junk crank on my hands too. Now I'm figuring the oil-starved engine might not be any worse than this one. Hopefully the third time is the charm.

After pulling the cover off, it was apparent that this head would be junk. The cams were pretty much fried and the journals weren't much better.

I was never able to get this engine to crank by hand, so I knew it was going to be seized up somewhere. The upper portion of the oil pan looked like a battle field. There were gooey, sparkly clumps everywhere. At least with this type of failure, the oil pump is all ready empty by the time the bearings disintegrate, so this stuff doesn't have a chance to circulate.

In order to get the rotating assembly out of the block, I had to pound the pistons out from the bottom with my 3lb hammer and a pry-bar against the under-side of the piston. Cylinder #2 and #4 came out easily, but #1 and #3 fought back. The rod caps on #1 and #3 also never came off the crank journals. However, at that point, the crank came out of the block easily.

With the internals out of the block, it really didn't look that bad. All of the carnage took place between the crank and rods. The cylinders are scoured, but the main journals look good. I also had a good crank, rods, and pistons that I acquired a while back that I loaded into my car with these two blocks and headed off to the machine shop again. I left the oil starved block there with the bin of internals.

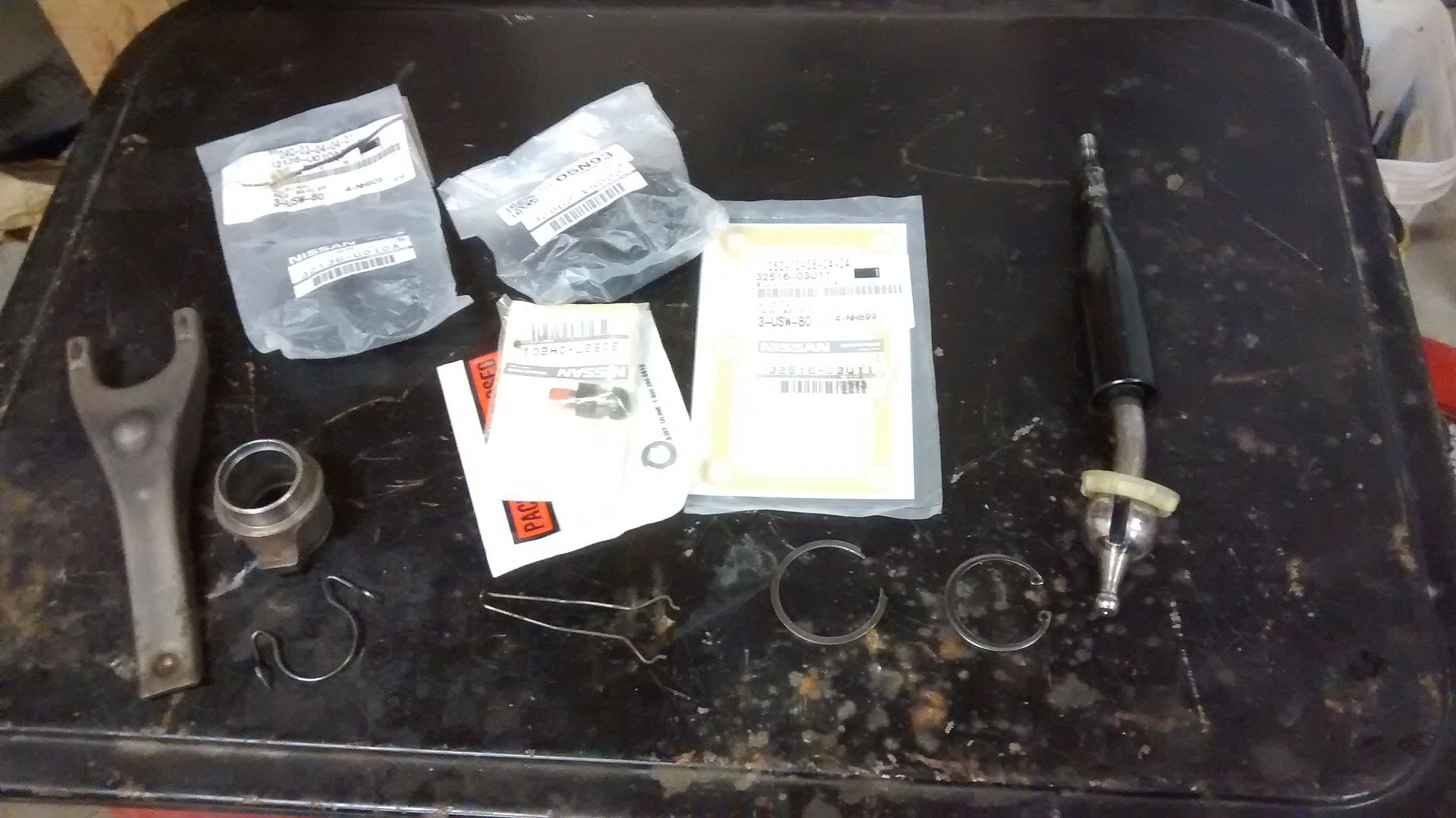

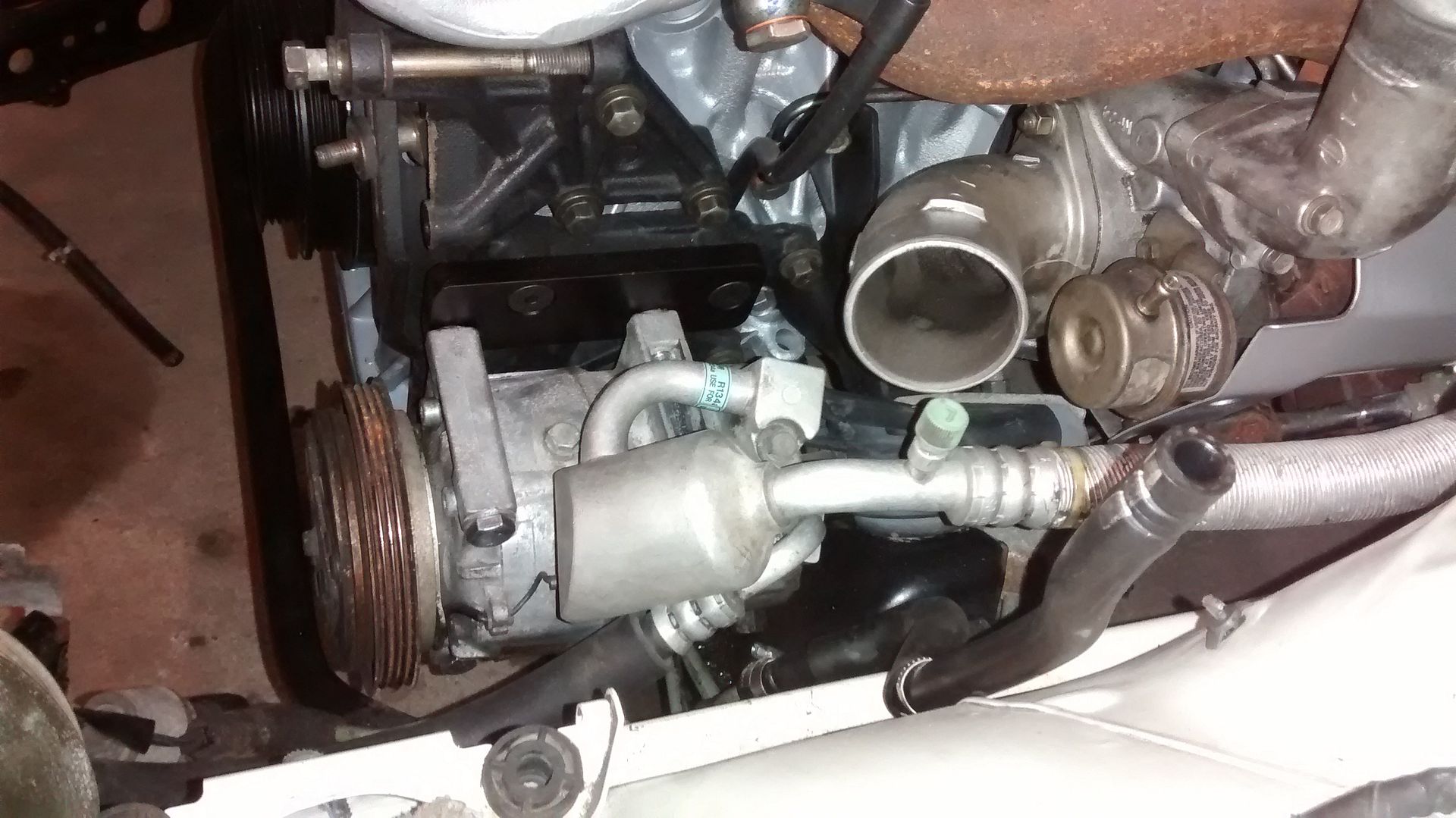

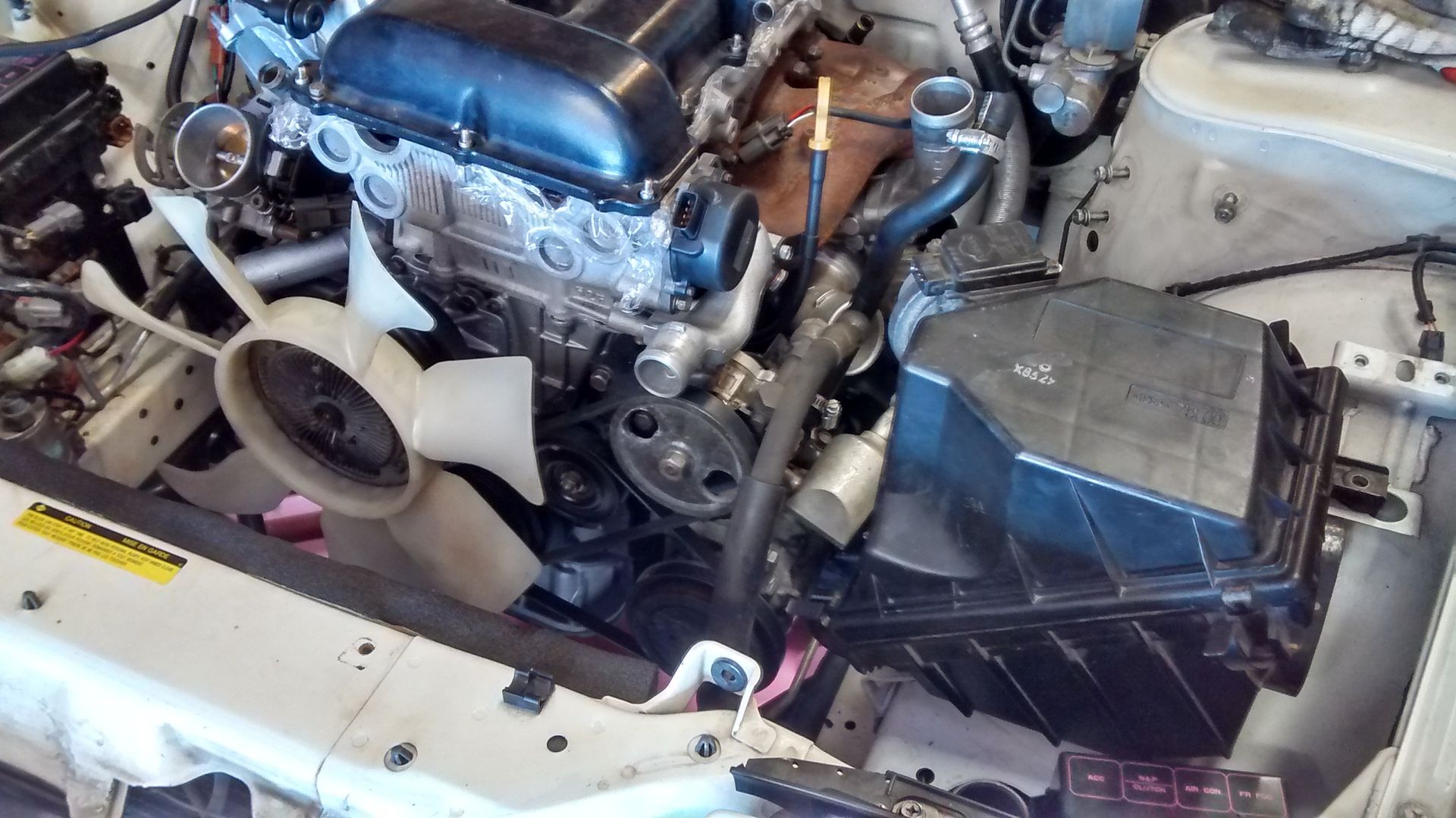

Moving forward, the plan is to order a replacement piston and a new set of rings and punch the oil-starved block out to 87mm. The Wiseco pistons will get pinned to a set of stock connecting rods which will be align bored with ARP rod bolts. This rotating assembly will get fully balanced. The mains will get align honed with ARP main studs. Finally the block will get decked for an OEM "felt" gasket. I'll be using the head from engine #2 that had the blue-green cover. I need to tear it down and replace the seals and put it back together with the BC hardware. I'll be installing a set of Tomei 256 Poncams and clamp it back on the block with more ARP hardware. Now it's just a matter of time - and money.