I do indeed have torque wrenches - 1/2" drive and 1/4" drive (for smaller things). I used the 1/4" drive for everything (including the UIM bolts which were torqued to 168 in lb - all other bolts for brackets torqued between 85-90 in lb). I didn't have the proper hex key that fit the throttle body, so my friend/helper just screwed it back in with some sort of ghetto arrangement of an Allen key and some pliers (similar to how we removed the TB in the first place). It took us maybe 3.5 hours total time actually spent over the span of 9 hours - we had a lot of distractions (a couch arrived at my house, we had to run out to get food, and we needed to go to said friend's house to retrieve said Allen key) and I spent some time cleaning the UIM and throttle body well. I used no sort of liquid gasket. The gaskets are metal-backed and quite sturdy, I could've probably cleaned and reused the old ones, but decided not to for good measure. When opening the throttle body gasket from the plastic bag it came in I tore the bag with too much force and bent the gasket, but I simply bent it back into shape carefully and used it. I'm sure it flattened out completely during reassembly.

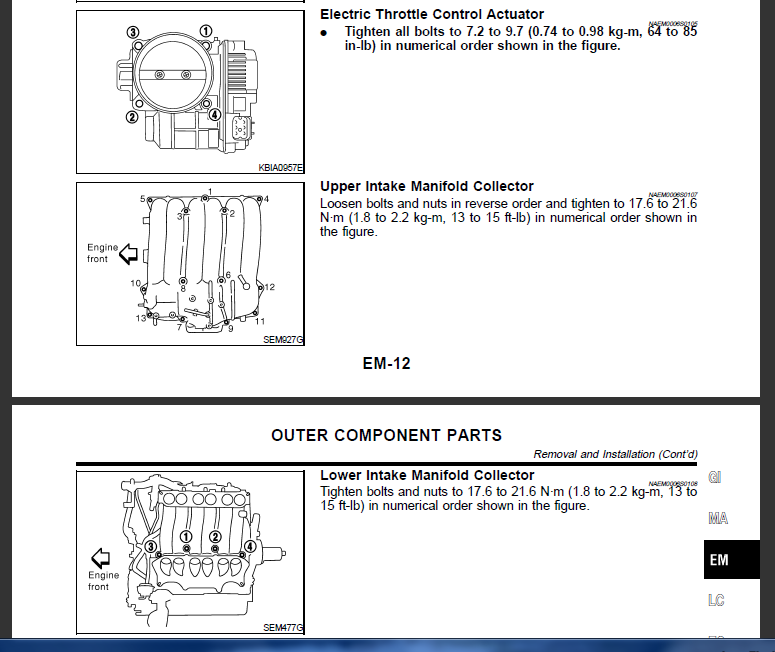

I went by the dealership earlier to see if they'd torque the TB, but their computers were down (I had a printout of the FSM page with the torque spec and tightening order, ha) but they were also swamped with customers. Service adviser said I could come back later, but I had to go to class 50 miles away. Nothing fell apart and everything was fine (had a couple short WOT runs), so I'm not awfully worried. I'm thinking the dealer will charge me though since the intake tube must be removed, so perhaps I'll just find another friend with the proper hex key and I'll retorque it myself. FSM says to replace throttle body gasket every time it's "removed" but I wouldn't be removing it completely, just loosening bolts then tightening to spec in order per FSM, so I'll use my day-old gasket.