Stuck Crank Bolt

- FlawleZ

- Posts: 112

- Joined: Sun Dec 08, 2013 9:37 am

- Car: 1992 Nissan 300ZX TT

1987 Nissan 300ZX Turbo

2017 Nissan Titan SV 4x4

Stuck Crank Bolt

So my harmonic balancer has a wobble to it. Time to replace. I go to remove the crank pulley and it's mega stuck. I've tried 1200 lb impacts, huge cheater bars, you name it. Ive even tried using a mapp gas torch. Is there a way to lock the crank pulley? The bolt refuses to budge. Anyone else run into this? Any ideas?

- Ilya

- Moderator

- Posts: 9867

- Joined: Fri Apr 23, 2010 11:20 pm

- Car: 2011 M56x but I spend a lot of time on my 2015 Kawasaki Vulcan S. Former owner of a 2007 M35x. Also take care of my wife's 2016 QX60.

- Location: Charlotte, NC

- Contact:

Re: Stuck Crank Bolt

Wow...if impact tools, etc. can't remove it I'm not sure what you can do. IIRC (don't quote me on this) but I remember people back in the day use to turn over the motor with a bar lodged someplace that would keep it from rotating? Sounds like a good chance of breaking something but...perhaps worth a google lol.

-

ArmedAviator

- Posts: 526

- Joined: Tue Mar 22, 2016 5:28 pm

- Car: 2012 M37x

- Location: SW Ohio

Re: Stuck Crank Bolt

I've bumped the starter with a breaker bar on the bolt a few times in the past. Surprisingly nothing went wrong, but don't take my word for it.

Usually an impact wrench is all that's needed. Spray it down with alot of PB Blaster twice a day over a few days and give it another shot. Be prepared for ruined crank threads, though.....if you're not able to bore and tap new threads in the crank snout yourself, than it's best to take it to a mechanic for the job. Trust me, it's no fun and if it's not perfectly aligned or done right, you need a new crank.

Usually an impact wrench is all that's needed. Spray it down with alot of PB Blaster twice a day over a few days and give it another shot. Be prepared for ruined crank threads, though.....if you're not able to bore and tap new threads in the crank snout yourself, than it's best to take it to a mechanic for the job. Trust me, it's no fun and if it's not perfectly aligned or done right, you need a new crank.

Re: Stuck Crank Bolt

IIRC, there is a type of object referenced in the 2006 M45 FSM that is wedged in the access hole to the crank plate/flywheel while you break the crank bolt loose. That makes me think an appropriately shaped metal object back there will do the job just fine without breaking teeth. Otherwise, the other method is jamming the crankshaft with a wooden hammer handle but that requires oil pan removal.FlawleZ wrote:So my harmonic balancer has a wobble to it... Is there a way to lock the crank pulley? The bolt refuses to budge. Anyone else run into this? Any ideas?

On other ideas, I've used the starter bump method which is not usually my preference due to the risk to the crankshaft threads as mentioned above. A push button ignition means you've gotta have some quick action. However, a part of me thinks this would be your best try if it won't respond to an impact gun. I preferred the cheater bar hanging out of the lower driver side so that it would beat on the ground instead of the vehicle structure. Long enough to ensure it beats on something and stops before whipping around and tearing stuff, but short enough to enable the end to travel a little and gain momentum (over 15 degress, if you can)

I haven't used this other method for breaking the bolt loose, but it came in handy for tightening the bolt. I have a sampling of V belts lying around. I took one that fit in the crank pulley grooves well (might not have been the correct width or number of V's bit it definitely came from another Nissan product), looped it around the pulley and put a rubber mallet on the other end. Then I twisted the mallet as much as I could and jammed it on some crossmember down there. It might take some retwisting, but it worked like a charm. For this, you'll need a big boy or a big cheater bar, or both.

If I may ask, any ideas as to what caused the wobble in the first place?

- FlawleZ

- Posts: 112

- Joined: Sun Dec 08, 2013 9:37 am

- Car: 1992 Nissan 300ZX TT

1987 Nissan 300ZX Turbo

2017 Nissan Titan SV 4x4

Re: Stuck Crank Bolt

I might try the starter bump method. Really wanted to avoid that. No idea what caused the wobble, but here's a video I took where you can see it.

https://youtu.be/SxVL5rAXYUU

https://youtu.be/SxVL5rAXYUU

Re: Stuck Crank Bolt

Thanks for the link. I watched your video a few times and even slowed it down to .25x speed for 2 of the viewings. You can definitely see the pulley wobble and the belt dancing on the tensioner beside it - accelerated wear on both the belt and tensioner bearings possible.

I have to go and look at the pulley I have to see exactly how the M45 pulley is assembled, but assuming there is rubber sandwiched somewhere, I'm curious if you can slowly turn the pulley to see what part of it is slightly offset so that you just pull it back out using a soft material pry bar.

Do you know if any engine work has been done to your car?

How many miles on it and where are you located?

I have to go and look at the pulley I have to see exactly how the M45 pulley is assembled, but assuming there is rubber sandwiched somewhere, I'm curious if you can slowly turn the pulley to see what part of it is slightly offset so that you just pull it back out using a soft material pry bar.

Do you know if any engine work has been done to your car?

How many miles on it and where are you located?

- FlawleZ

- Posts: 112

- Joined: Sun Dec 08, 2013 9:37 am

- Car: 1992 Nissan 300ZX TT

1987 Nissan 300ZX Turbo

2017 Nissan Titan SV 4x4

Re: Stuck Crank Bolt

120K on the car. I'm the 3rd owner and nothing other than typical maintenance has been done to my knowledge. The car has been well taken care of. I've owner it the last 2.5 years. I have a couple pictures of the pulley itself I'll post a little later. By the way, no parts store sells the harmonic balancer. They all say dealer only item. I called Infiniti and they want $560 just for the pulley.

Re: Stuck Crank Bolt

That's not a typical wear item on the Nissans I have dealt with, especially not the way I remember the m45 pulley. I reckon it takes some hammering to offset the pulley.

I'm in the process of moving and house hunting across state lines, but towards the end of the week I'll be able to look at my extra pulley and see if I'm in a position to help.

I'm in the process of moving and house hunting across state lines, but towards the end of the week I'll be able to look at my extra pulley and see if I'm in a position to help.

- FlawleZ

- Posts: 112

- Joined: Sun Dec 08, 2013 9:37 am

- Car: 1992 Nissan 300ZX TT

1987 Nissan 300ZX Turbo

2017 Nissan Titan SV 4x4

Re: Stuck Crank Bolt

I agree it's unusual wear. I can't find anything online or anyone else with an M45 that experienced this or even anyone that has had to remove the harmonic balancer. I purchased another used one from an 03 M45 that's in better shape. I'm just unable to remove the bolt on mine.

Thanks for your help.

Thanks for your help.

-

ArmedAviator

- Posts: 526

- Joined: Tue Mar 22, 2016 5:28 pm

- Car: 2012 M37x

- Location: SW Ohio

Re: Stuck Crank Bolt

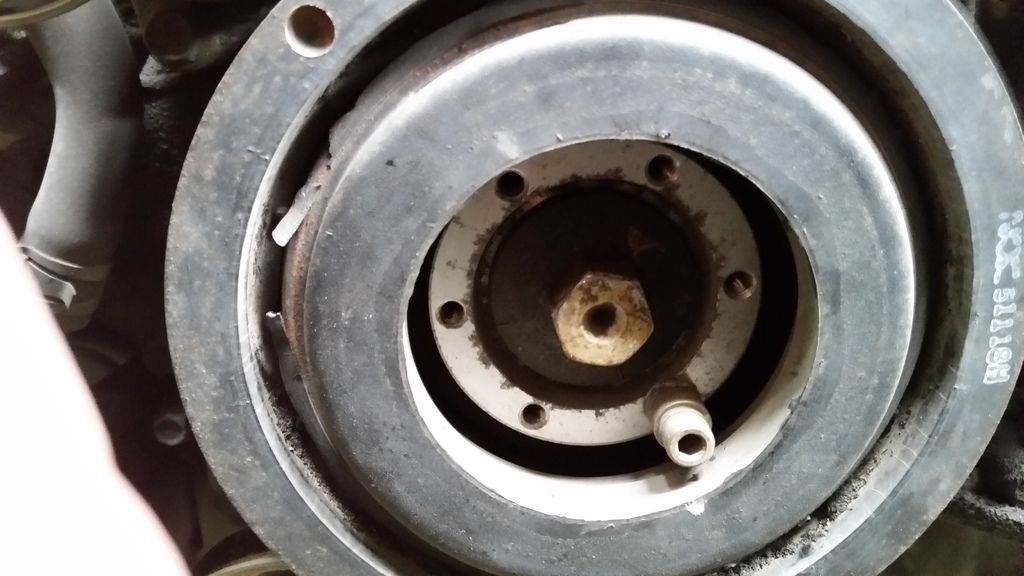

Amazingly looks like your threads are fine. Be sure to use a NEW bolt and torque it properly. The bolts are likely torque to yield which have specific torque instructions.

- FlawleZ

- Posts: 112

- Joined: Sun Dec 08, 2013 9:37 am

- Car: 1992 Nissan 300ZX TT

1987 Nissan 300ZX Turbo

2017 Nissan Titan SV 4x4

Re: Stuck Crank Bolt

Here's the two balancers in comparison. The pulley at top is the '06 from my car and the lower is from the '03 parts car. Notice the right edge appears thin on the uppermost balancer pictured.

In fact, it was so thin it broke in my hand.

A better look at the separation:

Here's another shot of them side by side. The '03 is on the right. Notice it has 4 divots at the top vs 2 on the '06.

In fact, it was so thin it broke in my hand.

A better look at the separation:

Here's another shot of them side by side. The '03 is on the right. Notice it has 4 divots at the top vs 2 on the '06.

-

The00Dustin

- Posts: 1042

- Joined: Mon Jun 29, 2009 4:05 am

- Car: 2006 M45

- Location: Bloomington, IN

Re: Stuck Crank Bolt

OP already got the thing loose, and I don't know enough to recommend the starter method, but I'm pretty sure "quick action" isn't an option with the push button and programming combination in mf 06 M45. It used to be possible to trip a starter with just a screwdriver, so I should imagine it would still be possible with some kind of jumper. So, in case anyone needs this thread in the future, is that still possible, and is it still safe for an engine? I ask because I would think this scenario (that I wouldn't want to perform regardless) would only need the starter to crank and don't actually need any other ignition systems going.EdBwoy wrote:On other ideas, I've used the starter bump method which is not usually my preference due to the risk to the crankshaft threads as mentioned above. A push button ignition means you've gotta have some quick action. However, a part of me thinks this would be your best try if it won't respond to an impact gun. I preferred the cheater bar hanging out of the lower driver side so that it would beat on the ground instead of the vehicle structure. Long enough to ensure it beats on something and stops before whipping around and tearing stuff, but short enough to enable the end to travel a little and gain momentum (over 15 degress, if you can)

- FlawleZ

- Posts: 112

- Joined: Sun Dec 08, 2013 9:37 am

- Car: 1992 Nissan 300ZX TT

1987 Nissan 300ZX Turbo

2017 Nissan Titan SV 4x4

Re: Stuck Crank Bolt

I was very leary of trying the starter bump for this reason. For what it's worth, I was able to get the bolt off with my impact, it just required a lot of heat. I actually switched it to tighten briefly, gave it a second or two, then switched back to reverse and it zipped off.The00Dustin wrote:OP already got the thing loose, and I don't know enough to recommend the starter method, but I'm pretty sure "quick action" isn't an option with the push button and programming combination in mf 06 M45. It used to be possible to trip a starter with just a screwdriver, so I should imagine it would still be possible with some kind of jumper. So, in case anyone needs this thread in the future, is that still possible, and is it still safe for an engine? I ask because I would think this scenario (that I wouldn't want to perform regardless) would only need the starter to crank and don't actually need any other ignition systems going.EdBwoy wrote:On other ideas, I've used the starter bump method which is not usually my preference due to the risk to the crankshaft threads as mentioned above. A push button ignition means you've gotta have some quick action. However, a part of me thinks this would be your best try if it won't respond to an impact gun. I preferred the cheater bar hanging out of the lower driver side so that it would beat on the ground instead of the vehicle structure. Long enough to ensure it beats on something and stops before whipping around and tearing stuff, but short enough to enable the end to travel a little and gain momentum (over 15 degress, if you can)

Re: Stuck Crank Bolt

Quick action is indeed possible with the push button, I would say that is what made all my idle air relearn attempts successful.The00Dustin wrote:OP already got the thing loose, and I don't know enough to recommend the starter method, but I'm pretty sure "quick action" isn't an option with the push button and programming combination in mf 06 M45. It used to be possible to trip a starter with just a screwdriver, so I should imagine it would still be possible with some kind of jumper. So, in case anyone needs this thread in the future, is that still possible, and is it still safe for an engine? I ask because I would think this scenario (that I wouldn't want to perform regardless) would only need the starter to crank and don't actually need any other ignition systems going.EdBwoy wrote:On other ideas, I've used the starter bump method which is not usually my preference due to the risk to the crankshaft threads as mentioned above. A push button ignition means you've gotta have some quick action...

And you can also use a jumper, i suppose. The location of the starter makes it less ideal for me to squeeze in there to try and do it. I feel safer doing it from inside the vehicle.

As far as safety to the engine (regardless of method used), I cannot immediately think of any harm to it rather than possible damage to the threads. The aim is not to run the engine for a long time, just enough of a rotation for the bolt to break loose.

If the concern is turning a crankshaft with no fuel and spark, then consider that the first few moments of the starting process is actually just turning the crankshaft and if the sensor doesn't get any rotation, fuel isn't fed in nor are the plugs fired... or I could also compare it to push starting a manual car.

-

The00Dustin

- Posts: 1042

- Joined: Mon Jun 29, 2009 4:05 am

- Car: 2006 M45

- Location: Bloomington, IN

Re: Stuck Crank Bolt

I haven't tried to cancel a start after starting it, so my experience is more anecdotal. I suppose it depends on your definition of "quick" amongst other things. While the idle air relearn procedure does require some timed patterns, I haven't performed it either, so I don't know whether or not the starter should/could be quickly engaged/disengaged during that procedure. I do know that pressing the buttons three times fast to kill the engine while moving doesn't take if the times are too fast, and I do know that I see noticeable delays in all electronic systems in the vehicle, however, if "quick" means seconds vs fractions, then my concerns are moot. As to damage, my concerns would be as follows:EdBwoy wrote:Quick action is indeed possible with the push button, I would say that is what made all my idle air relearn attempts successful.The00Dustin wrote:OP already got the thing loose, and I don't know enough to recommend the starter method, but I'm pretty sure "quick action" isn't an option with the push button and programming combination in mf 06 M45. It used to be possible to trip a starter with just a screwdriver, so I should imagine it would still be possible with some kind of jumper. So, in case anyone needs this thread in the future, is that still possible, and is it still safe for an engine? I ask because I would think this scenario (that I wouldn't want to perform regardless) would only need the starter to crank and don't actually need any other ignition systems going.

And you can also use a jumper, i suppose. The location of the starter makes it less ideal for me to squeeze in there to try and do it. I feel safer doing it from inside the vehicle.

As far as safety to the engine (regardless of method used), I cannot immediately think of any harm to it rather than possible damage to the threads. The aim is not to run the engine for a long time, just enough of a rotation for the bolt to break loose.

If the concern is turning a crankshaft with no fuel and spark, then consider that the first few moments of the starting process is actually just turning the crankshaft and if the sensor doesn't get any rotation, fuel isn't fed in nor are the plugs fired... or I could also compare it to push starting a manual car.

1) Damage to the starter if the bolt didn't give

2) Damage to sensors/timing when turning the engine by jumping the starter (vs using the button)

- FlawleZ

- Posts: 112

- Joined: Sun Dec 08, 2013 9:37 am

- Car: 1992 Nissan 300ZX TT

1987 Nissan 300ZX Turbo

2017 Nissan Titan SV 4x4

Re: Stuck Crank Bolt

Honestly, if the bolt doesn't give the starter will just round it off at the head. My impact was starting to do that itself.

Re: Stuck Crank Bolt

The starter is pretty torquey, and factor that with whatever the gear reduction is on the flywheel. The starter will be fine sonce the tooh profile between it and the flywheel ensures perfect engagement (ideally) . In my experience, if the starter doesn't turn it the first time, it tries 2 other times and just stops. I figured the ECM determines when to stop per button push so it doesn't overheat and cause other damage.

No damage to any sensors or timing (chain still keeps time) that I can think of.

OP, I somehow missed your other posts with the pictures. I would expect more wear on the pulley teeth since the belt is scrubbing around. You saw wear on the front surface as well?

No damage to any sensors or timing (chain still keeps time) that I can think of.

OP, I somehow missed your other posts with the pictures. I would expect more wear on the pulley teeth since the belt is scrubbing around. You saw wear on the front surface as well?

- FlawleZ

- Posts: 112

- Joined: Sun Dec 08, 2013 9:37 am

- Car: 1992 Nissan 300ZX TT

1987 Nissan 300ZX Turbo

2017 Nissan Titan SV 4x4

Re: Stuck Crank Bolt

No wear on the front surface. Just the visible separate in the rubber section. Severe wear on the back side from the wobble in which you can see in the pic above. The belts are rubber and the balancer is steel so I wouldn't think there would ever be wear. The belt should disintegrate first.EdBwoy wrote:The starter is pretty torquey, and factor that with whatever the gear reduction is on the flywheel. The starter will be fine sonce the tooh profile between it and the flywheel ensures perfect engagement (ideally) . In my experience, if the starter doesn't turn it the first time, it tries 2 other times and just stops. I figured the ECM determines when to stop per button push so it doesn't overheat and cause other damage.

No damage to any sensors or timing (chain still keeps time) that I can think of.

OP, I somehow missed your other posts with the pictures. I would expect more wear on the pulley teeth since the belt is scrubbing around. You saw wear on the front surface as well?

Re: Stuck Crank Bolt

Glad you got it off. Did you heat the bolt directly?

- FlawleZ

- Posts: 112

- Joined: Sun Dec 08, 2013 9:37 am

- Car: 1992 Nissan 300ZX TT

1987 Nissan 300ZX Turbo

2017 Nissan Titan SV 4x4

Re: Stuck Crank Bolt

Yes but really the washer part since that's what is holding on so hard.dTardis wrote:Glad you got it off. Did you heat the bolt directly?

-

BlackCat81

- Posts: 422

- Joined: Mon Sep 21, 2015 4:09 am

- Car: 2006 M35x

2003 Lexus GX470 - Location: Mesa, AZ

Re: Stuck Crank Bolt

Ya, we have a special tool that locks the flywheel in place so you can crank on it. My 1,200ftlb Impact won't get one off. I use a 3' half in. Breaker bar with another 2 feet of pipe on the end to break them loose. Pretty normal.

- FlawleZ

- Posts: 112

- Joined: Sun Dec 08, 2013 9:37 am

- Car: 1992 Nissan 300ZX TT

1987 Nissan 300ZX Turbo

2017 Nissan Titan SV 4x4

Re: Stuck Crank Bolt

Yup. Just very frustrating to do with the engine in the car still and no way to lock the torque converter. The balancer also doesn't have any useable windows or holes to lodge something in.

Re: Stuck Crank Bolt

How is the repair holding up?

You said at some point the heat was enough to make the balancer smoke. I was concerned, but it seems the crank seal was not affected negatively at all, right?

Also, I wanted to take back my advice on using a belt to tighten the pulley. It's not the best way - the rubber could wear prematurely. Ask me how I know.

Did you just use the impact tool on the way back?

You said at some point the heat was enough to make the balancer smoke. I was concerned, but it seems the crank seal was not affected negatively at all, right?

Also, I wanted to take back my advice on using a belt to tighten the pulley. It's not the best way - the rubber could wear prematurely. Ask me how I know.

Did you just use the impact tool on the way back?

- FlawleZ

- Posts: 112

- Joined: Sun Dec 08, 2013 9:37 am

- Car: 1992 Nissan 300ZX TT

1987 Nissan 300ZX Turbo

2017 Nissan Titan SV 4x4

Re: Stuck Crank Bolt

Repair is holding up well. The bolt, seal, etc. all were not impacted from the heat required to remove it previously. I didn't use the impact to tighten completely I finished by hand.EdBwoy wrote: ↑Mon Jan 15, 2018 9:35 amHow is the repair holding up?

You said at some point the heat was enough to make the balancer smoke. I was concerned, but it seems the crank seal was not affected negatively at all, right?

Also, I wanted to take back my advice on using a belt to tighten the pulley. It's not the best way - the rubber could wear prematurely. Ask me how I know.

Did you just use the impact tool on the way back?

Re: Stuck Crank Bolt

How do you keep it from spinning if tightening it by hand, I had to tighten one on an 05 maxima and couldn't really figure it out so I just used an impact

Re: Stuck Crank Bolt

Re: Stuck Crank Bolt

Anyone know how to remove a broken crankshaft bolt