The new sender switch arrived, I now have the tools needed to change the switch and run the test. I wanted to get tool pictures up a soon as possible as I've had some questions questions from members about the tools.

The good news about the Harbor Freight pressure testing kit is it has several fittings that match the threads on the OEM switch. So the kit provides several options for elbow, extension, union, and the hose fitting appears to use the same thread type.

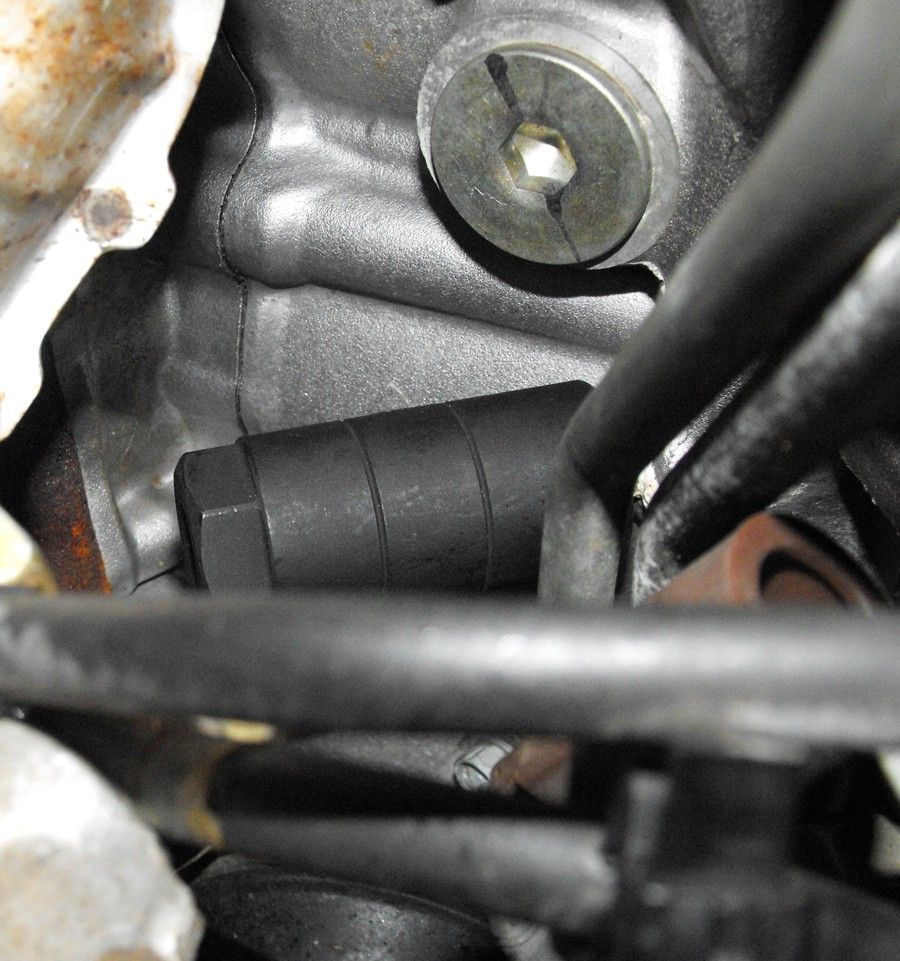

The pictures below show tools and the new switch where I tested the thread pattern.

Two things I have already planned that will make this operation easier are:

1) Remove the Power Rack to install the Energy Suspension bushings and replace the bellows.

2) Replace the stock 29mm anti-sway bar with a 28mm from a Q45a.

Combining the switch replacement (and oil pressure test) with the other activities, should make the operation much easier. If I could get the car up another 10 to 12 inches or to a fully extended jack stand position, all three operations will be a lot easier.