I suppose since this is official "day one" of me actually making an attempt to do this swap I should probably start documenting my progress.

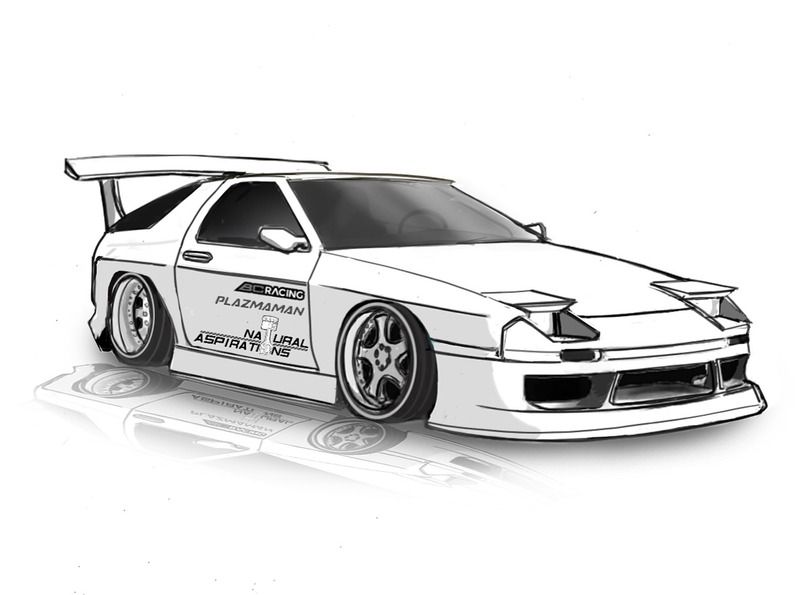

I had recently come to a stopping point with my '69 510 that I had been working on for the last year and apparently the word had gotten out that I was bored and needed a new project. I received a random text that there was an FC chassis a friend of a friend was trying to get rid of and was free for the taking. Myself being a Subaru and Datsun guy (weird mix I know) I was skeptical about the idea of a Mazda yet very excited about the idea of another obscure project. I decided to go take a look at it and upon arrival I realized that it was overall pretty clean. Additionally, the interior and engine were removed to include all four rotten tires, which wasn't really an issue. We bomb back over to my house and grab my spares and swap out the wheels. Shortly after, a phone call was made to the local towing company and the RX-7 was picked up and on its way to its new home.

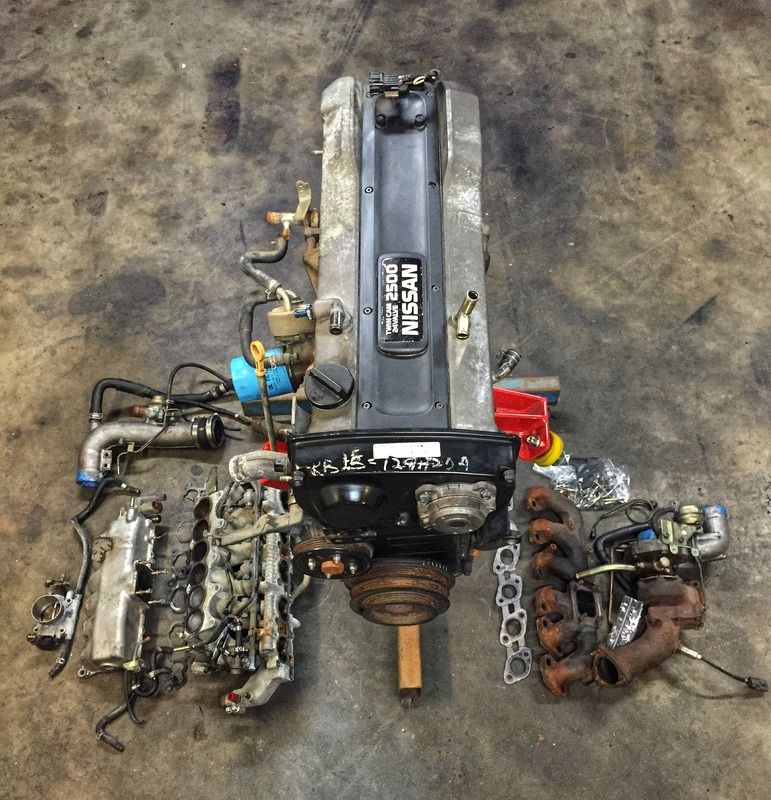

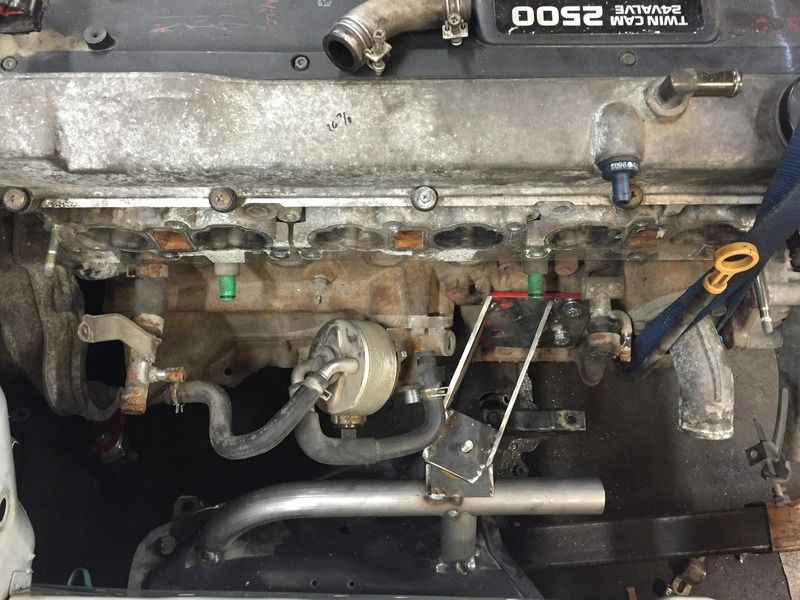

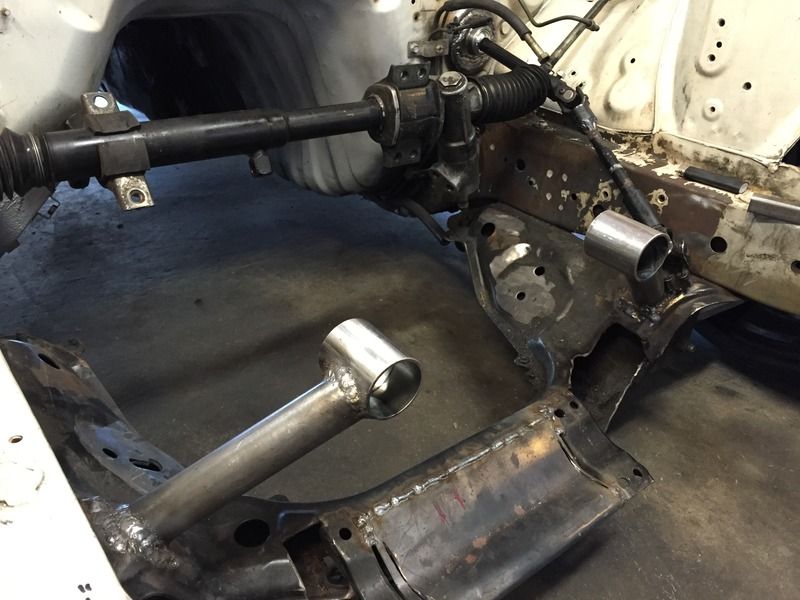

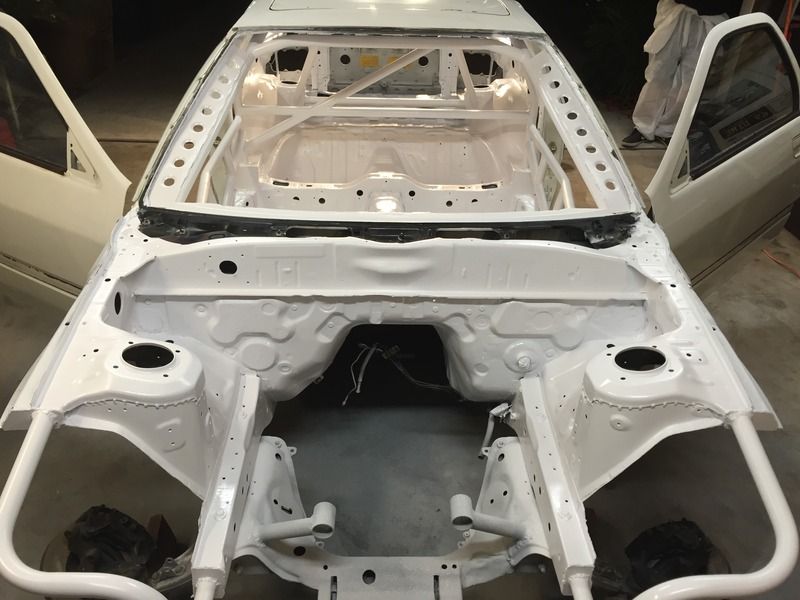

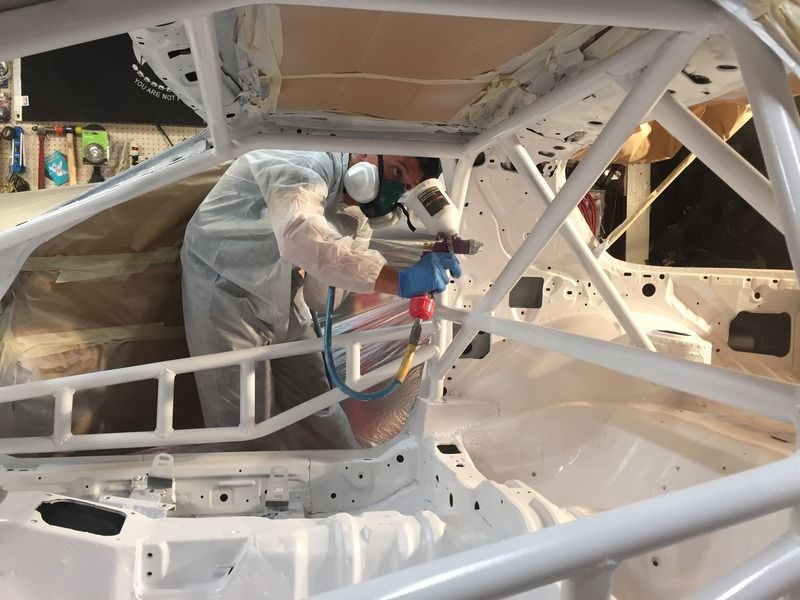

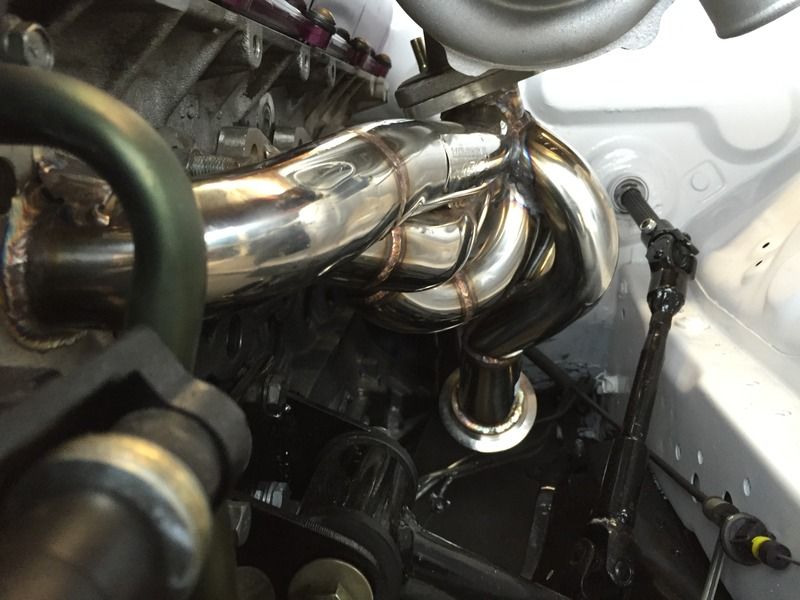

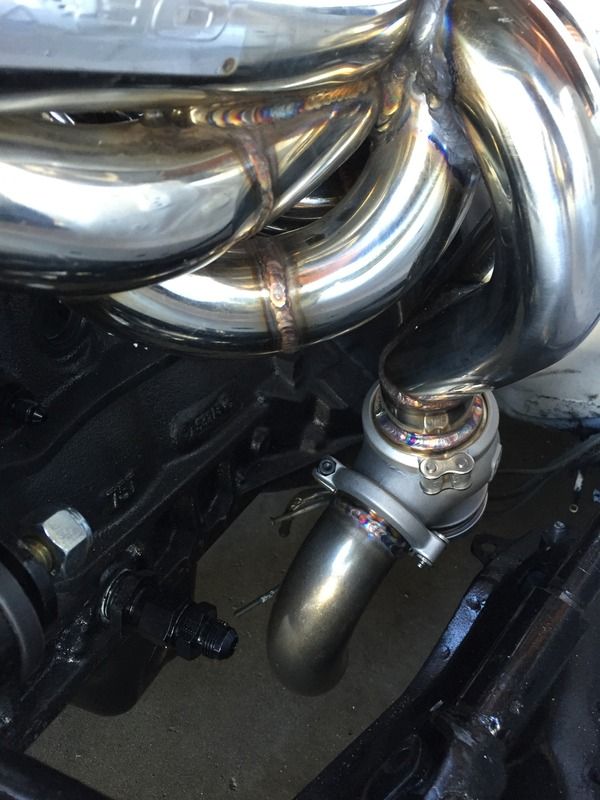

A couple days went by and I was contemplating on what engine to put in this beauty. I tossed around the idea of a LS, which bored me and I mildly entertained the JZ craze, but again didn't excite me by the unavailability of a decent transmission and commonality of the engines these days. I then decided that it needed something a bit more interesting and felt the desire to dive into some uncharted territory. I knew of an RB25DET swap in a S30 that was potentially for sale, so I called the friend and made an offer on the swap. To my surprise, the offer was accepted and another phone call I had a truck lined up to seal the deal. After I got the engine home and got it set up appropriately on a stand, I stripped all the stuff I assumed I wouldn't be needing and made an overall assessment of the purchase.