1999 Maxima Knock Sensor Input Voltage Question

1999 Maxima Knock Sensor Input Voltage Question

It never fails, come time to renew the registration things start cropping up to detour from making it thru emissions. This time it's been a left bank upstream O2 sensor, a #6 coil pack and the darn PO 325 / knock sensor code that keeps coming back. I've done some research, checked out the manuals(invaluable resource here) and here's where I'm at.

The knock sensor ohm's out at 553 which is a good value, however the voltage at the F121 connector(where the sub-harness that connects to the knock sensor plugs into the engine harness) with the key on is only 3.34 volts vs. the 5 volts it's supposed to be. Possibly this low voltage is why it keeps registering the PO 325 code in the computer after I clear it?? I don't know enough about the engine wiring harness routing to know how it routes to the ECM......is there a bulkhead fitting going thru the firewall or ?? I'd like to back probe the wire (white??/the knock sensor '64' pin location on the ECM) at the firewall to check for 5 volts without having to mess with going into the cabin of the car to access or remove the ECM connnector. Has anyone dealt with this low voltage problem before or know where I can find decent access to the white wire/knock sensor lead to back probe it to see if the ECM is outputting 5 volts??

I'm sure hoping it's something simple and not a bad voltage output from the ECM.

The knock sensor ohm's out at 553 which is a good value, however the voltage at the F121 connector(where the sub-harness that connects to the knock sensor plugs into the engine harness) with the key on is only 3.34 volts vs. the 5 volts it's supposed to be. Possibly this low voltage is why it keeps registering the PO 325 code in the computer after I clear it?? I don't know enough about the engine wiring harness routing to know how it routes to the ECM......is there a bulkhead fitting going thru the firewall or ?? I'd like to back probe the wire (white??/the knock sensor '64' pin location on the ECM) at the firewall to check for 5 volts without having to mess with going into the cabin of the car to access or remove the ECM connnector. Has anyone dealt with this low voltage problem before or know where I can find decent access to the white wire/knock sensor lead to back probe it to see if the ECM is outputting 5 volts??

I'm sure hoping it's something simple and not a bad voltage output from the ECM.

- centralcoaster33

- Posts: 2769

- Joined: Tue Apr 05, 2005 10:41 am

- Car: 240SX #5-1997

- Location: Central Coast, CA

Re: 1999 Maxima Knock Sensor Input Voltage Question

1999? The knock sensor could very well be cracked in the housing at this point. All the testing you are asking about, along with pins and such is described in your FSM. Haynes and Chilton are okay for basics, but not nearly as good for specifics imho. Are you using that? If not, start!  Here's a link:

Here's a link:

http://www.nicoclub.com/FSM/Maxima/1999/

EC chapter page 300

http://www.nicoclub.com/service-manual? ... ma/1999/EC

FSM says 2-3 volts... you are correct about the resistance 500-620... I hope I'm not misunderstanding you.

Anyway, hopefully it's easy to get at. That seems to be the hardest part about the knock sensor, their location on the engine block.

http://www.nicoclub.com/FSM/Maxima/1999/

EC chapter page 300

http://www.nicoclub.com/service-manual? ... ma/1999/EC

FSM says 2-3 volts... you are correct about the resistance 500-620... I hope I'm not misunderstanding you.

Anyway, hopefully it's easy to get at. That seems to be the hardest part about the knock sensor, their location on the engine block.

Re: 1999 Maxima Knock Sensor Input Voltage Question

You are correct about the location of the knock sensor being a PITA to access. I have just enough room to fit my hand in there......... and the cuts and scrapes to go with it. I've had the knock sensor off and inspected it and did a ohm's test on it which spec'ed out o.k. , I've looked at a number of Maximas in the boneyard and have seen the cracked knock sensor housings. I also had initially bought a knock sensor off of Amazon, one that was told to me that the Nissan guys use, and had installed it thinking that the OEM knock sensor was bad. That was before I did more research and learned about ohm-ing out the sensor and finding out about what the voltages should be. The Amazon sensor was NIB and did *not* give me any ohm reading, zilch/nota/nothing........money down the drain. I was doing a side by side comparison with the OEM knock sensor that I'd removed from the car originally.centralcoaster33 wrote:1999? The knock sensor could very well be cracked in the housing at this point. All the testing you are asking about, along with pins and such is described in your FSM. Haynes and Chilton are okay for basics, but not nearly as good for specifics imho. Are you using that? If not, start!Here's a link:

http://www.nicoclub.com/FSM/Maxima/1999/

EC chapter page 300

http://www.nicoclub.com/service-manual? ... ma/1999/EC

FSM says 2-3 volts... you are correct about the resistance 500-620... I hope I'm not misunderstanding you.

Anyway, hopefully it's easy to get at. That seems to be the hardest part about the knock sensor, their location on the engine block.

I have availed myself, as noted in the OP, of the FSM's listed here on NICO. They have been very helpful. What I don't have is knowledge of the actual routing of the engine wiring harness loom and how it paths to the ECM.

The FSM does say 2-3 volts when hooked up to the knock sensor installed on the engine block. However what I found is that the voltage feed, when the sub-harness is disconnected from the knock sensor, is not the 5 volts it should be. It's only 3.34 volts so the knock sensor is not going to be able to function as it's designed with that lower voltage being fed to it. Hence, the reason I think the ECM keeps registering a PO 325 code.

- centralcoaster33

- Posts: 2769

- Joined: Tue Apr 05, 2005 10:41 am

- Car: 240SX #5-1997

- Location: Central Coast, CA

Re: 1999 Maxima Knock Sensor Input Voltage Question

Okay, gotcha. I have a 240sx. Tonight, I can put a voltmeter on there and see what kind of voltage I get. I think I understand your assumption. The computer sends 5V, it passes through resistance and get's measured at less volts. But, I'm thinking this might not be the case. That the ECU sends the 3 volts, or whatever.

Hmm, how about bypassing all the wire routing and sticking your probe right onto the pin from the back of the ECU and seeing what voltage you have at that end of things? You should be able to find which pin in the FSM.

Weird about that Amazon sensor. Did you measure resistance from the two prongs or, from the one prong and the metal center/ backside ground?

Hmm, how about bypassing all the wire routing and sticking your probe right onto the pin from the back of the ECU and seeing what voltage you have at that end of things? You should be able to find which pin in the FSM.

Weird about that Amazon sensor. Did you measure resistance from the two prongs or, from the one prong and the metal center/ backside ground?

Re: 1999 Maxima Knock Sensor Input Voltage Question

As I understand it the knock sensor gets fed 5 volts from the ECM , the design of the knock sensor basically balances that voltage at around 2.5 volts. If there is any vibration/harmonic(knock) in the range the knock sensor is designed to detect that changes that 2.5-ish voltage. That change is noted by the ECM and it changes the timing.....or at least that is kinda how I've been learning that it works!!????centralcoaster33 wrote:Okay, gotcha. I have a 240sx. Tonight, I can put a voltmeter on there and see what kind of voltage I get. I think I understand your assumption. The computer sends 5V, it passes through resistance and get's measured at less volts. But, I'm thinking this might not be the case. That the ECU sends the 3 volts, or whatever.

Hmm, how about bypassing all the wire routing and sticking your probe right onto the pin from the back of the ECU and seeing what voltage you have at that end of things? You should be able to find which pin in the FSM.

Weird about that Amazon sensor. Did you measure resistance from the two prongs or, from the one prong and the metal center/ backside ground?

Yes, the FSM has provided all the information needed to determine which pin on the ECM is outputting the knock sensor voltage. However I really don't want to have to disconnect the main wiring connector on the ECM.....until it's determined that the voltage output on that pin 64 is incorrect. I'd much rather back probe it out in the engine compartment to verify what's happening first.....does that make sense or am I approaching it wrong??

Regarding the Amazon knock sensor I measured it from the prong that receives the voltage to the metal center/backside ground. I also measured from the non-utilized prong to the metal center/backside ground, every time I was doing the exact same check on the OEM knock sensor. The OEM knock sensor always registered the correct ohms and the Amazon one did nothing.

- centralcoaster33

- Posts: 2769

- Joined: Tue Apr 05, 2005 10:41 am

- Car: 240SX #5-1997

- Location: Central Coast, CA

Re: 1999 Maxima Knock Sensor Input Voltage Question

Okay, I measured mine as I said I would. It rang up 4.89 volts with engine not running, but on for ecu power and accessory. I measured my power input wire (the white wire) to my battery ground, unplugged from the knock sub harness. I checked my FSM for similar diagnoses. Nowhere does it tell me to test for 5v there or 2-3v elsewhere.

However, your FSM does say to test for 2-3 volts. Specifically on the wire coming from the ECU. It also says to test that against it's ground at 25. You aren't doing that. Then it talks about testing continuity from ecu to sub harness, then sub to knock. You've got power, but assume it's less. Testing ohms across your harness could be a clue and can't hurt.

There is no back probing at the firewall, just your harness ends at ecu, sub-harness plug and knock sensor. You might as well follow the FSM and get into your panel and hope for a voltage of 2-3 as directed. 3.34 I guess would be a high number, so knock detected or bad sensor. Your sensor test in ohms was good so that leads back to actual knock.

If what you are suggesting is true (that you should have 5v and only get 3.34 so your ECU is malfunctioning), then you're gonna be in there anyway, to replace the ecu.

However, your FSM does say to test for 2-3 volts. Specifically on the wire coming from the ECU. It also says to test that against it's ground at 25. You aren't doing that. Then it talks about testing continuity from ecu to sub harness, then sub to knock. You've got power, but assume it's less. Testing ohms across your harness could be a clue and can't hurt.

There is no back probing at the firewall, just your harness ends at ecu, sub-harness plug and knock sensor. You might as well follow the FSM and get into your panel and hope for a voltage of 2-3 as directed. 3.34 I guess would be a high number, so knock detected or bad sensor. Your sensor test in ohms was good so that leads back to actual knock.

If what you are suggesting is true (that you should have 5v and only get 3.34 so your ECU is malfunctioning), then you're gonna be in there anyway, to replace the ecu.

Re: 1999 Maxima Knock Sensor Input Voltage Question

Thank you 'centralcoaster33' for checking and verifying that your white wire voltage, disconnected connector that feeds the voltage to the knock sensor, was darn close to 5 volts with key on /non running.centralcoaster33 wrote:Okay, I measured mine as I said I would. It rang up 4.89 volts with engine not running, but on for ecu power and accessory. I measured my power input wire (the white wire) to my battery ground, unplugged from the knock sub harness. I checked my FSM for similar diagnoses. Nowhere does it tell me to test for 5v there or 2-3v elsewhere.

However, your FSM does say to test for 2-3 volts. Specifically on the wire coming from the ECU. It also says to test that against it's ground at 25. You aren't doing that. Then it talks about testing continuity from ecu to sub harness, then sub to knock. You've got power, but assume it's less. Testing ohms across your harness could be a clue and can't hurt.

There is no back probing at the firewall, just your harness ends at ecu, sub-harness plug and knock sensor. You might as well follow the FSM and get into your panel and hope for a voltage of 2-3 as directed. 3.34 I guess would be a high number, so knock detected or bad sensor. Your sensor test in ohms was good so that leads back to actual knock.

If what you are suggesting is true (that you should have 5v and only get 3.34 so your ECU is malfunctioning), then you're gonna be in there anyway, to replace the ecu.

Referencing this thought;

" You might as well follow the FSM and get into your panel and hope for a voltage of 2-3 as directed. 3.34 I guess would be a high number, so knock detected or bad sensor. " .

There might be some misunderstanding in the above thought. The 3.34 volts I had mentioned is the key-on 3.34 voltage that I had measured at the F23-F121 connector junction *with* the knock sensor sub-harness disconnected. Same thing you did when you got 4.89 volts. Meaning there was no voltage going to the knock sensor I was just checking for the required 5 volts inputting voltage. I'm not assuming it's "low voltage" it is low voltage vs. the system designed 5 volts input to the knock sensor and other sensors on the engine. I need to figure out where the drop is and maybe back probing the terminal 64 at the ECM will answer that question!??

I saw that 'ECM Terminals and Reference Value' section on page EC-300 of the 'Trouble Diagnostic For DTC PO325' . If you noticed the "condition" provided was 'Engine is running @ idle speed' . Sooo that reference of 2.0-3.0 volts is with the knock sensor wiring connected and the internals of the knock sensor providing a resistance drop from the 5 volts that it is supposed to be feed with. The reading you were referencing in the FSM (2.0-3.0 volts) was with the engine running and the knock sensor connected. This same method of checking is also shown in the video I'm going to address below.

When you say "get into your panel" I'm presuming you mean the mounting location of the ECM inside of the car accessed from the driver's side of the counsel?? Heck, I've never been inside of there to know how things are configured with the ECM mounting and access to the main wiring harness connector. As of right now I don't know if there is access for one to back probe the # 64 terminal to get the voltage reading?? It seems that taking the back probe reading at the terminal where the sub-harness to the knock sensor connects to the main engine harness would provide the same result........ unless there is resistance/voltage drop somewhere between the ECM and the knock sensor sub-harness connector!??

I checked with a friend that does vehicle electrical/computer diagnostic work(unfortunately he's nowhere close to help out) and he mentioned that all vehicles with computer control/engine sensors use a standard of 5 volts going to the sensors. I don't know why they don't mention it in the FSM but in this video by 'EricTheCarGuy' he does provide reference to the 5 volts. Here is the link;

https://www.youtube.com/watch?v=W2cFuheKBgQ

I know this is not a Nissan in the video however it is about a faulty knock sensor diagnostic. Starting at 15:05 in this video he explains the test method regarding having the 5 volt reference signal at the terminal feed to the knock sensor and then back probing the connector. The back probing is done after the sub-harness is plugged back into the bolted down to the engine block knock sensor. So key on status and check the operational voltage(2-3 volts DC per what is noted in the Nissan FSM) to tell the status of the knock sensor.

I'm heading outside to perform the resistance test to the engine ground bolts as detailed on page EC 302 knock sensor diagnostic procedure and dig into this further. Guess it's also time to dig into the ECM mounting and figure out what I'm up against there!! :-)

- centralcoaster33

- Posts: 2769

- Joined: Tue Apr 05, 2005 10:41 am

- Car: 240SX #5-1997

- Location: Central Coast, CA

Re: 1999 Maxima Knock Sensor Input Voltage Question

Yeah, I follow. I'm familiar with the typical 5v sub-systems. I'm just not ready to jump on the assumption bandwagon... yet. For me to do that, I'd want to test my knock sensor by back-probing my ECU pins to see the 2-3v instead of the near 5V coming from the ECU. I admit, it's a task I don't want to do. I also feel, even if I did do it, that information would only lead to you having to dig further and do it on your end, so either way, you're going to have to do it there. Also, I didn't put much effort into elaborating on my thoughts and assumptions, mostly out of being tired from work and not wanting to type so much. I will say, I appreciate your putting such effort into your posts. Props sir. Your understanding of the knock system is spot on with mine, minus the 5V assumption, that's all.

In an attempt to clarify -

I measured 4.89V. No surprise. You measured 3.34v. Surprise! In that situation, with the assumption that you should have gotten near 5v, it looks like there could be something wrong with your ECU. If so, it would need to be replaced. You would want to be sure of that before doing it, so you'd get in there and do some further testing. Possibly checking a few other 5v pins to see what you get for power readings, like, say the TPS.

Since things weren't doing what we assumed they'd do, specifically the reading of 3.34v and since we're not testing what the FSM says to test, then I started to wonder if perhaps you'd get that 3.34 between the pins 64 and 25. And, that would be a number out of range, so you'd potentially have knock. That of course would not jive with our basic understanding of the system nor with our assumptions, so I was merely investigating an alternative.

Yes, 'getting in there' is referring to accessing your ECU pins and that end of your engine harness.

Another thing I was eluding to, but not writing, is that your actual harness may need repair. So, you'd want to check the continuity between the pin for the ecu and the pin for the knock sensor sub-harness. The continuity test will give you Ohms resistance. So my thinking was that perhaps the harness has a short in it and that is 'sucking' power out of the path to the knock sensor.

As far as getting in there goes, it's not really difficult or even that time consuming, harder to type and explanation imho. You'll pull your passenger door sill trim, then the front kick panel trim. There's the ECU, mounted to chassis. Take screws out, pull ECU into a position giving you access to the plug on the back. Use a pic, Exacto or something to remove the arched plastic cover over the plug and wires, it's snapped into the plug itself along two edges. You may find removing the screwed on plug will help with access. You will likely find that it does help with seeing where the pins are that match your pin-out diagram. Put the plug back in and screw it on. Use "T" pins to back probe. Sink a "T" pin into the back of the wires on the pins you're interested in (64 and 25). Use your alligator clips on the tester to clip onto the "T" pins.

Because you're dealing with a powered ECU and running engine, be certain you are testing the correct pins! Do not accidentally ground or jump anything. Be sure, then test.

In an attempt to clarify -

I measured 4.89V. No surprise. You measured 3.34v. Surprise! In that situation, with the assumption that you should have gotten near 5v, it looks like there could be something wrong with your ECU. If so, it would need to be replaced. You would want to be sure of that before doing it, so you'd get in there and do some further testing. Possibly checking a few other 5v pins to see what you get for power readings, like, say the TPS.

Since things weren't doing what we assumed they'd do, specifically the reading of 3.34v and since we're not testing what the FSM says to test, then I started to wonder if perhaps you'd get that 3.34 between the pins 64 and 25. And, that would be a number out of range, so you'd potentially have knock. That of course would not jive with our basic understanding of the system nor with our assumptions, so I was merely investigating an alternative.

Yes, 'getting in there' is referring to accessing your ECU pins and that end of your engine harness.

Another thing I was eluding to, but not writing, is that your actual harness may need repair. So, you'd want to check the continuity between the pin for the ecu and the pin for the knock sensor sub-harness. The continuity test will give you Ohms resistance. So my thinking was that perhaps the harness has a short in it and that is 'sucking' power out of the path to the knock sensor.

As far as getting in there goes, it's not really difficult or even that time consuming, harder to type and explanation imho. You'll pull your passenger door sill trim, then the front kick panel trim. There's the ECU, mounted to chassis. Take screws out, pull ECU into a position giving you access to the plug on the back. Use a pic, Exacto or something to remove the arched plastic cover over the plug and wires, it's snapped into the plug itself along two edges. You may find removing the screwed on plug will help with access. You will likely find that it does help with seeing where the pins are that match your pin-out diagram. Put the plug back in and screw it on. Use "T" pins to back probe. Sink a "T" pin into the back of the wires on the pins you're interested in (64 and 25). Use your alligator clips on the tester to clip onto the "T" pins.

Because you're dealing with a powered ECU and running engine, be certain you are testing the correct pins! Do not accidentally ground or jump anything. Be sure, then test.

Re: 1999 Maxima Knock Sensor Input Voltage Question

I checked the voltage, again, at that disconnected sub-harness to the knock sensor and it was still 3.34 volts.XPLRN wrote:

When you say "get into your panel" I'm presuming you mean the mounting location of the ECM inside of the car accessed from the driver's side of the counsel?? Heck, I've never been inside of there to know how things are configured with the ECM mounting and access to the main wiring harness connector. As of right now I don't know if there is access for one to back probe the # 64 terminal to get the voltage reading?? It seems that taking the back probe reading at the terminal where the sub-harness to the knock sensor connects to the main engine harness would provide the same result........ unless there is resistance/voltage drop somewhere between the ECM and the knock sensor sub-harness connector!??

Guess it's also time to dig into the ECM mounting and figure out what I'm up against there!! :-)

Went looking for the ECM.......this is new territory for me.........driver's side;

Passenger side;

I'm presuming this is the ECM...........how does one go about doing a back probe on #64 terminal of the harness connector on the passenger side with that plastic shield over it?? All I'm wanting to figure out is if there is 5 volts being outputted at ECM on the #64 pin/wire to the knock sensor, suggestions??

- centralcoaster33

- Posts: 2769

- Joined: Tue Apr 05, 2005 10:41 am

- Car: 240SX #5-1997

- Location: Central Coast, CA

Re: 1999 Maxima Knock Sensor Input Voltage Question

Yeah, that's it. You want to take off that plastic cover with the cross-hatching, but not the whole plug and wires. I wonder if you posted while I was typing and me vice versa. Did you see my back probe explanation with T pins? I don't know how to write that any other way.

As far as testing the pin for voltage by itself (not as the FSM has directed us to do), I would unplug that knock sensor at the sub-harness. I would put the key into the on position and not start the car. This gives power to the ECU and accessory systems. Then, I would test for voltage between the one wire (using the pin back-probe method) and a good ground on your chassis. I don't see one in the picture, but you could look nearby. Often the ECU harness has a ball of ground wires coming out and going to the chassis nearby. Otherwise, you could pick any ground in the engine bay by using an extension wire for your tester wires.

That is all in addition to the testing the FSM recommends.

You will want an extension wire for the ability to test continuity between this plug and your plugs in the engine bay, (harness wire test per FSM).

As far as testing the pin for voltage by itself (not as the FSM has directed us to do), I would unplug that knock sensor at the sub-harness. I would put the key into the on position and not start the car. This gives power to the ECU and accessory systems. Then, I would test for voltage between the one wire (using the pin back-probe method) and a good ground on your chassis. I don't see one in the picture, but you could look nearby. Often the ECU harness has a ball of ground wires coming out and going to the chassis nearby. Otherwise, you could pick any ground in the engine bay by using an extension wire for your tester wires.

That is all in addition to the testing the FSM recommends.

You will want an extension wire for the ability to test continuity between this plug and your plugs in the engine bay, (harness wire test per FSM).

Re: 1999 Maxima Knock Sensor Input Voltage Question

Thank you very much for all the info you have shared. I did post up some pictures of what I "thought" was the ECM. However your directive above, in underlined and bold highlight, leads me to think maybe I'm on the wrong path!??centralcoaster33 wrote: Possibly checking a few other 5v pins to see what you get for power readings, like, say the TPS.

Since things weren't doing what we assumed they'd do, specifically the reading of 3.34v and since we're not testing what the FSM says to test, then I started to wonder if perhaps you'd get that 3.34 between the pins 64 and 25. And, that would be a number out of range, so you'd potentially have knock. That of course would not jive with our basic understanding of the system nor with our assumptions, so I was merely investigating an alternative.

Yes, 'getting in there' is referring to accessing your ECU pins and that end of your engine harness.

Another thing I was eluding to, but not writing, is that your actual harness may need repair. So, you'd want to check the continuity between the pin for the ecu and the pin for the knock sensor sub-harness. The continuity test will give you Ohms resistance. So my thinking was that perhaps the harness has a short in it and that is 'sucking' power out of the path to the knock sensor.

As far as getting in there goes, it's not really difficult or even that time consuming, harder to type and explanation imho. You'll pull your passenger door sill trim, then the front kick panel trim. There's the ECU, mounted to chassis. Take screws out, pull ECU into a position giving you access to the plug on the back. Use a pic, Exacto or something to remove the arched plastic cover over the plug and wires, it's snapped into the plug itself along two edges. You may find removing the screwed on plug will help with access. You will likely find that it does help with seeing where the pins are that match your pin-out diagram. Put the plug back in and screw it on. Use "T" pins to back probe. Sink a "T" pin into the back of the wires on the pins you're interested in (64 and 25). Use your alligator clips on the tester to clip onto the "T" pins.

Because you're dealing with a powered ECU and running engine, be certain you are testing the correct pins! Do not accidentally ground or jump anything. Be sure, then test.

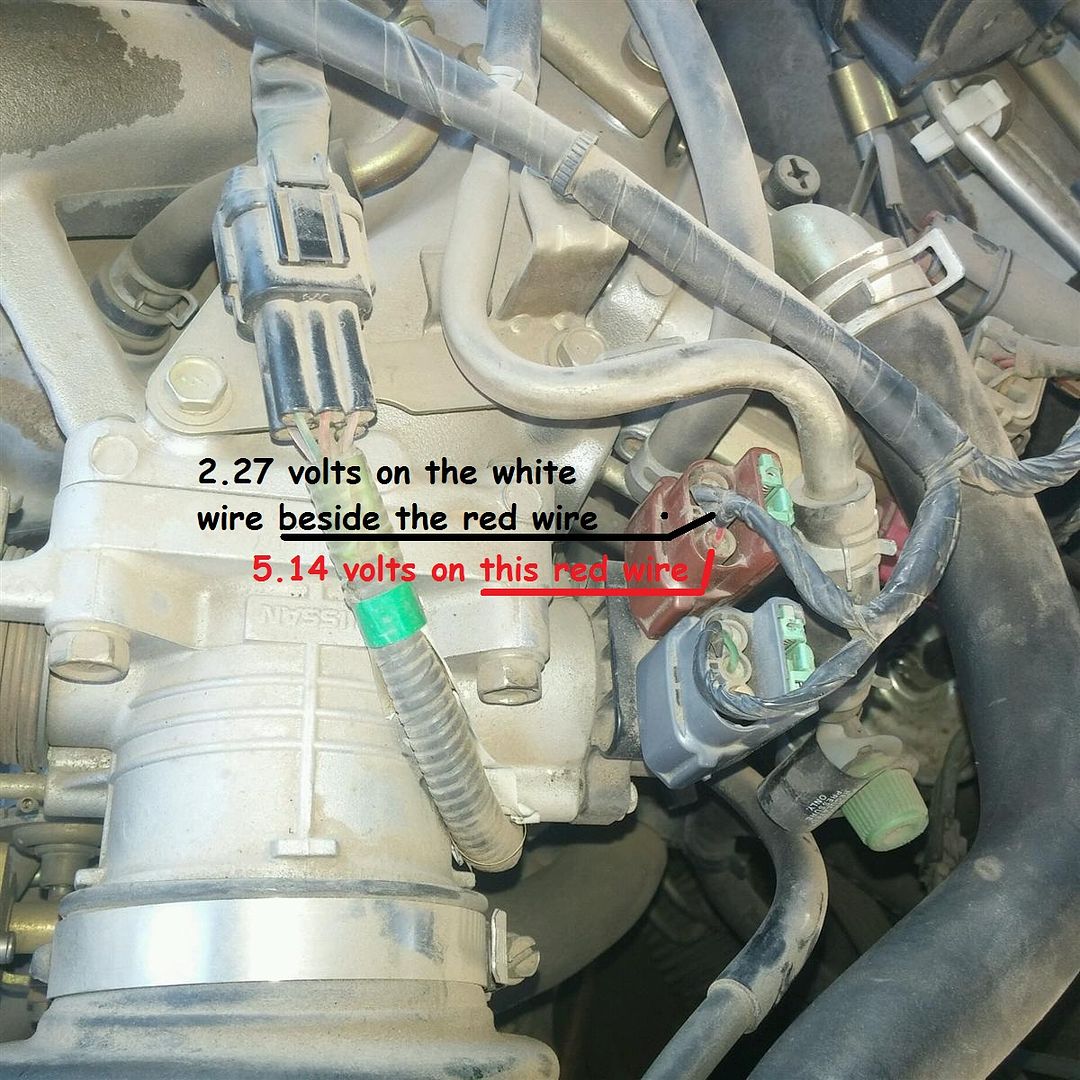

I did go out and check what I thought was the TPS for voltages and my findings are in the picture below.

Re: 1999 Maxima Knock Sensor Input Voltage Question

Thank you, again, for the information shared. Yes, I think we were posting while each other was typing and vice versa; cross talking. Anyways I went out and did a back probe on the voltage feed wire to the knock sensor, at the sub-harness connector in two different scenarios.centralcoaster33 wrote:Yeah, that's it. You want to take off that plastic cover with the cross-hatching, but not the whole plug and wires. I wonder if you posted while I was typing and me vice versa. Did you see my back probe explanation with T pins? I don't know how to write that any other way.

As far as testing the pin for voltage by itself (not as the FSM has directed us to do), I would unplug that knock sensor at the sub-harness. I would put the key into the on position and not start the car. This gives power to the ECU and accessory systems. Then, I would test for voltage between the one wire (using the pin back-probe method) and a good ground on your chassis. I don't see one in the picture, but you could look nearby. Often the ECU harness has a ball of ground wires coming out and going to the chassis nearby. Otherwise, you could pick any ground in the engine bay by using an extension wire for your tester wires.

That is all in addition to the testing the FSM recommends.

You will want an extension wire for the ability to test continuity between this plug and your plugs in the engine bay, (harness wire test per FSM).

1st scenario was; key on but engine not running = 2.24 volts

2nd scenario was; engine running = 2.01 volts

The 1st scenario voltage was not erratic/jumping around in that test as it was for the bad knock sensor in the 'EricTheCarGuy's video that I had linked in the previous post. The 2nd scenario voltage was also pretty stable.......but right on the low end of the FSM specifications. I sure wish there was a way to validate the 5 volt sensor feed other than that Wells tech guy that 'EricTheCarGuy' referenced in his video.

My next endeavor will be removing the plastic cover from the ECM and trying to access/back probe the #64 pin for key on voltage.

Re: 1999 Maxima Knock Sensor Input Voltage Question

**UPDATE** - Posting this up in case someone in the future has this same kind of issue

I had a conversation with a friend of mine that is a Toyota Dealership mechanic and knowledgeable on engine computer/sensor functions. He agreed about the five volts for sensor input voltage was standard design between manufacturers. I detailed to him all I'd done with checking the voltages and not wanting to mess with the ECM and ask him what he would do. His thought was to go buy a new knock sensor and try that. I checked at both O'rilleys and Autozone and since the Autozone was closer and best value for a life-time warrantied knock sensor I decided to go there. Before I left I decided to check the system one more time to see what had happened in the 38 miles I'd driven since I'd cleared the PO325 code. Son of a gun!! The green light(cleared for emissions testing!!) was on and I was THRILLED after all the messing around that I'd done. I had ask the salesman at the Autozone if I could ohm out the 'Duralast' knock sensor before I bought so I decided to go up there and at least check it out even though I didn't need it.........now anyways!! The knock sensor ohm-ed out at 544 which fell within the correct resistance range of 500-620, definitely within spec!!

Anyways I don't really know what I did that created the change to where the ECM stopped registering the PO325 code. I'll list a couple of things I did that might have influenced the change!??

1. When I had bought the new Amazon knock sensor and installed it I'd also bought/installed a new sub-harness coming off the the main engine harness. When I got into the whole diagnostics thing I learned about ohm-ing out the knock sensor and since the new Amazon knock sensor didn't seem to be functioning/kept throwing the PO325 code I decided to remove it and check it *and* the OEM knock sensor that I'd removed. Found out the Amazon knock sensor didn't register any ohms and the OEM knock sensor did ohm out in the correct range so I re-installed the OEM knock sensor. Could the new sub-harness have been the fix.........I don't know!??

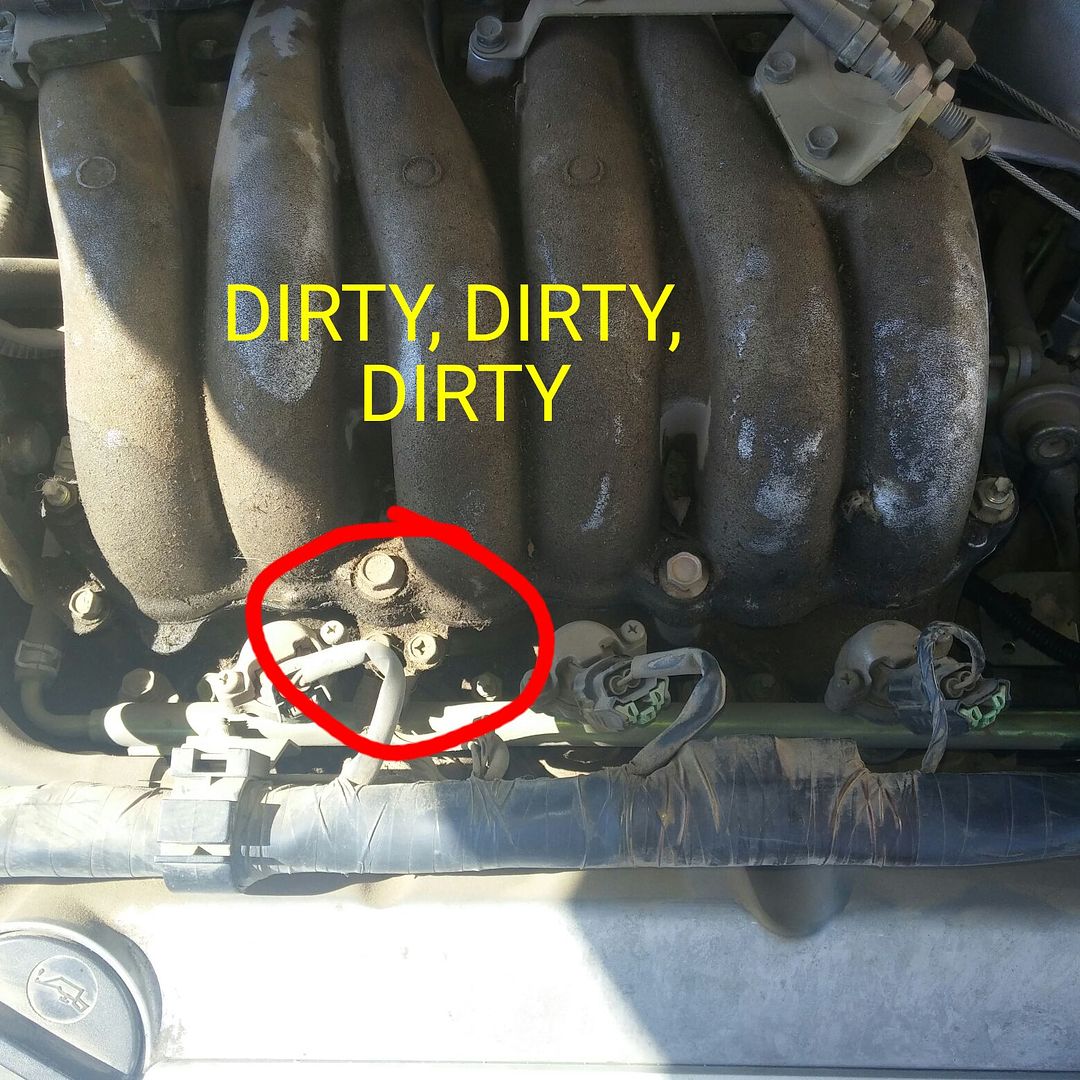

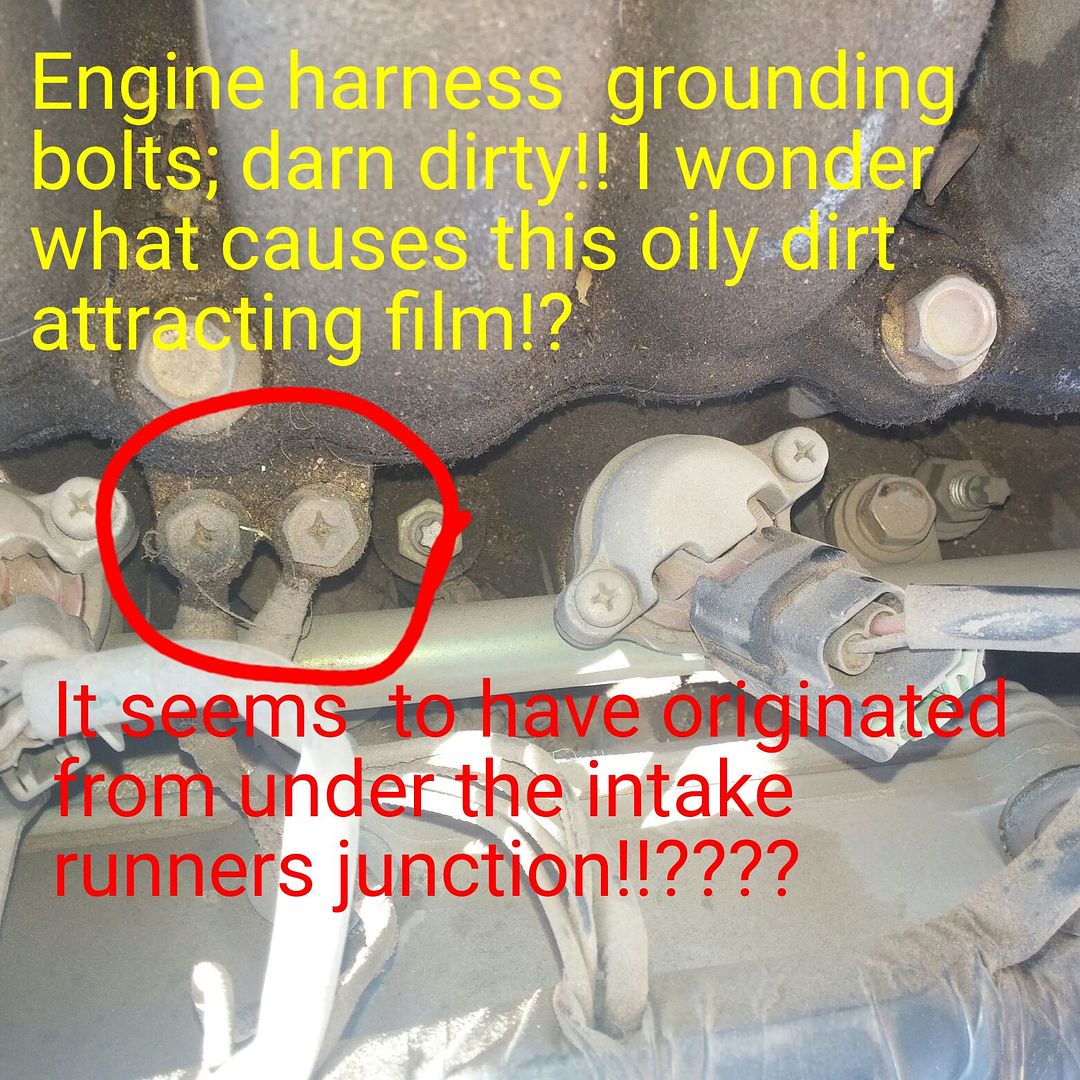

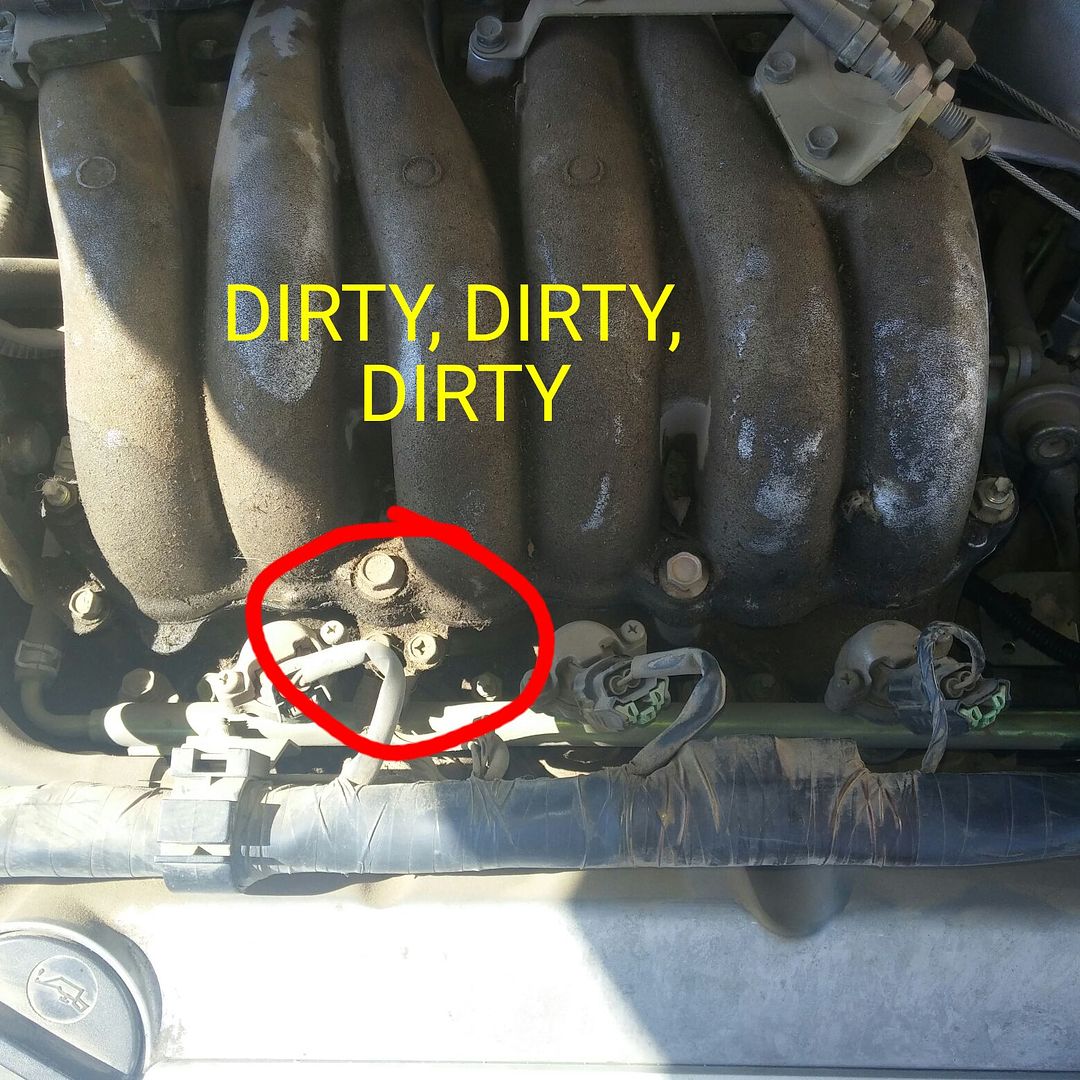

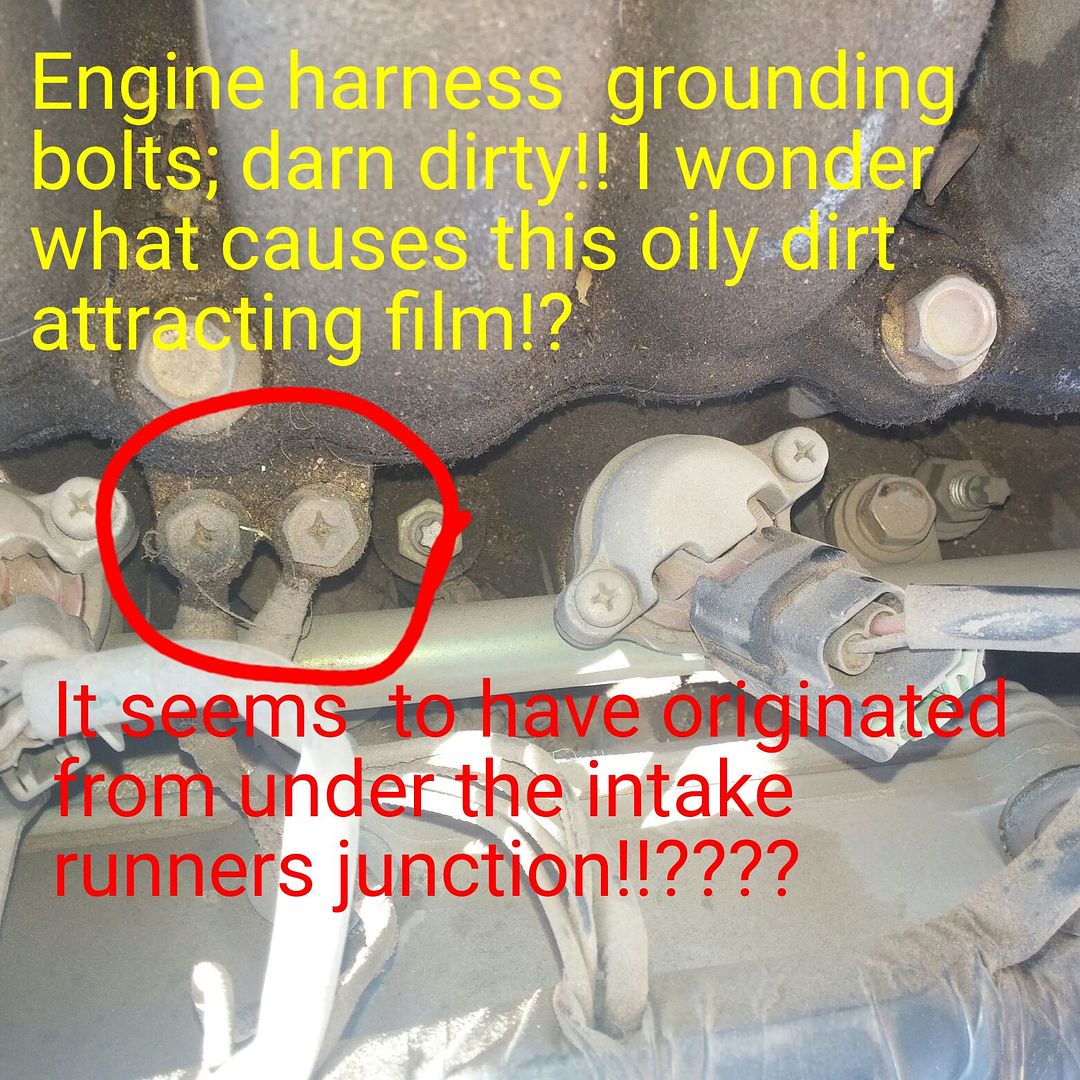

2. With the awesome reference aid of the NICO on-line FSM's, one of the things I learned was where the engine wiring harness ground bolts were located. For whatever reason they were covered with a oily dirt attracted residual that seemed to emulate from the intake runners to intake manifold mating area. I did clean that area off with carb cleaner and maybe, just maybe that had something to do with it!!???

Overall picture of the engine grounding bolts;

Closeup of engine grounding bolts;

I have to admit I don't know what caused the change from the yellow light/PO325 code continually registering on the Innova 3120 to the green 'good to go' emissions status. I never did anything to the ECM to check the output voltage of the # 64 terminal which feeds the knock sensor.

Tomorrow morning I'll print out yet another '3 day permit' and take the Maxima up to the emissions testing station. I will double check with the Innova 3120 tester when in line to make sure the green light/'good to go' emissions light is on. Hopefully it will still be registering green and they deem it 'good to go' !!! Then it will be another two years till we have to once again jump thru the emissions hoop!!! After I get back from running it thru emissions I will pull that sub-harness connector apart and check the key-on / non-engine running voltage again.........just to satisfy my curiosity!!

Thank you very much, 'centralcoaster33', for your continued input/support in this diagnostics saga!!

I had a conversation with a friend of mine that is a Toyota Dealership mechanic and knowledgeable on engine computer/sensor functions. He agreed about the five volts for sensor input voltage was standard design between manufacturers. I detailed to him all I'd done with checking the voltages and not wanting to mess with the ECM and ask him what he would do. His thought was to go buy a new knock sensor and try that. I checked at both O'rilleys and Autozone and since the Autozone was closer and best value for a life-time warrantied knock sensor I decided to go there. Before I left I decided to check the system one more time to see what had happened in the 38 miles I'd driven since I'd cleared the PO325 code. Son of a gun!! The green light(cleared for emissions testing!!) was on and I was THRILLED after all the messing around that I'd done. I had ask the salesman at the Autozone if I could ohm out the 'Duralast' knock sensor before I bought so I decided to go up there and at least check it out even though I didn't need it.........now anyways!! The knock sensor ohm-ed out at 544 which fell within the correct resistance range of 500-620, definitely within spec!!

Anyways I don't really know what I did that created the change to where the ECM stopped registering the PO325 code. I'll list a couple of things I did that might have influenced the change!??

1. When I had bought the new Amazon knock sensor and installed it I'd also bought/installed a new sub-harness coming off the the main engine harness. When I got into the whole diagnostics thing I learned about ohm-ing out the knock sensor and since the new Amazon knock sensor didn't seem to be functioning/kept throwing the PO325 code I decided to remove it and check it *and* the OEM knock sensor that I'd removed. Found out the Amazon knock sensor didn't register any ohms and the OEM knock sensor did ohm out in the correct range so I re-installed the OEM knock sensor. Could the new sub-harness have been the fix.........I don't know!??

2. With the awesome reference aid of the NICO on-line FSM's, one of the things I learned was where the engine wiring harness ground bolts were located. For whatever reason they were covered with a oily dirt attracted residual that seemed to emulate from the intake runners to intake manifold mating area. I did clean that area off with carb cleaner and maybe, just maybe that had something to do with it!!???

Overall picture of the engine grounding bolts;

Closeup of engine grounding bolts;

I have to admit I don't know what caused the change from the yellow light/PO325 code continually registering on the Innova 3120 to the green 'good to go' emissions status. I never did anything to the ECM to check the output voltage of the # 64 terminal which feeds the knock sensor.

Tomorrow morning I'll print out yet another '3 day permit' and take the Maxima up to the emissions testing station. I will double check with the Innova 3120 tester when in line to make sure the green light/'good to go' emissions light is on. Hopefully it will still be registering green and they deem it 'good to go' !!! Then it will be another two years till we have to once again jump thru the emissions hoop!!! After I get back from running it thru emissions I will pull that sub-harness connector apart and check the key-on / non-engine running voltage again.........just to satisfy my curiosity!!

Thank you very much, 'centralcoaster33', for your continued input/support in this diagnostics saga!!

Re: 1999 Maxima Knock Sensor Input Voltage Question

I checked the ECM when I got home last night, showed the green light status to my wife and was all happy. I did not check it this morning before I took off for the emissions testing station, after springing for yet another 3-day permit. Got to the emissions station, was in line, hooked up the Innova 3120 and checked the status...........SOB.......the thing threw the code again!!! I was not boxed in by anyone behind me so I backed up and took the emergency exit outa there.XPLRN wrote:

Tomorrow morning I'll print out yet another '3 day permit' and take the Maxima up to the emissions testing station. I will double check with the Innova 3120 tester when in line to make sure the green light/'good to go' emissions light is on. Hopefully it will still be registering green and they deem it 'good to go' !!!

I'm beyond frustrated...............

- centralcoaster33

- Posts: 2769

- Joined: Tue Apr 05, 2005 10:41 am

- Car: 240SX #5-1997

- Location: Central Coast, CA

Re: 1999 Maxima Knock Sensor Input Voltage Question

Damn! I was hoping to post a happy ending response. Then I saw your latest. I'll have to brain storm this a bit (plus I am at work). But to clear up again, I misdirected you to the ECU. You found yours fine and that is it in your photos. My directions were for a 240sx ECU location... Derp!

Do you have check engine light on at this time or does it just ring up with your scanner tool? What state emissions are you needing to pass?

Do you have check engine light on at this time or does it just ring up with your scanner tool? What state emissions are you needing to pass?

- centralcoaster33

- Posts: 2769

- Joined: Tue Apr 05, 2005 10:41 am

- Car: 240SX #5-1997

- Location: Central Coast, CA

Re: 1999 Maxima Knock Sensor Input Voltage Question

I'd unscrew the grounds on the engine, clean them and the engine, use a little dielectric grease and screw them back on. I read you sprayed them, I don't know if that was with or without unscrewing. I'd consider doing the same thing to the knock sensor screwed onto the engine. It needs good continuity to the block for ground. I'd use the dielectric grease, but in limited location. I'd check voltage as the FSM directed on the ECU. Since I'd be in the ECU backprobing, I'd check that pin for voltage to a ground on the chassis. I'd check for resistance across the engine harness wire. I'd put dielectric grease in the plugs of the sensor, sub-harness and harness, but not at the ECU. I'd be ready to buy a new sensor and install it. You are close. You must be. It nearly passed itself, then it forgot and failed itself.

Hmm, along this train of thought is the why?. Did this have anything to do with warm up? I mean a switch from cold start operation to normal temp operation? I think knock is ignored during cold routine, so... if you started and stopped and started and stopped your car a few times in a row, never getting up to operating temperature each time, then the computer had enough restarts without a triggered knock and tossed the code aside. It doesn't store them forever. Then, you finally get it up to normal operating temperature for test day and it finally looks at the sensor again and fails. Just a thought.

I guess you have a registration sticker issue. I wish you could do the above and then drive it around a while to make sure the code isn't returning, then take it to smog. Backroads at night maybe?

Hmm, along this train of thought is the why?. Did this have anything to do with warm up? I mean a switch from cold start operation to normal temp operation? I think knock is ignored during cold routine, so... if you started and stopped and started and stopped your car a few times in a row, never getting up to operating temperature each time, then the computer had enough restarts without a triggered knock and tossed the code aside. It doesn't store them forever. Then, you finally get it up to normal operating temperature for test day and it finally looks at the sensor again and fails. Just a thought.

I guess you have a registration sticker issue. I wish you could do the above and then drive it around a while to make sure the code isn't returning, then take it to smog. Backroads at night maybe?

Re: 1999 Maxima Knock Sensor Input Voltage Question

Thank you, again, for your mental review and thoughts of what I am up against with the on-going PO325 knock sensor code debacle. Your underlined assessment above(and other thoughts) made me chuckle, thanks, I needed some levity as this situation is dragging me down. I am in Arizona and unfortunately live in a area where the emissions compliance is a requirement. Regarding your thought on the switch from cold start operation to normal temp operation.....when I had the green light twice on Thursday night the car was definitely at operating temperature. The first time I'd just drove it 38 miles, then it was a trip to the gas station and came back and checked it again to see if there was any changes. I did not check it on Friday morning before I departed to the emissions station. It was definitely at operating temperature when I got in line and shut it off and checked for the green light again and it had threw the PO325 code again.centralcoaster33 wrote:I'd unscrew the grounds on the engine, clean them and the engine, use a little dielectric grease and screw them back on. I read you sprayed them, I don't know if that was with or without unscrewing. I'd consider doing the same thing to the knock sensor screwed onto the engine. It needs good continuity to the block for ground. I'd use the dielectric grease, but in limited location. I'd check voltage as the FSM directed on the ECU. Since I'd be in the ECU backprobing, I'd check that pin for voltage to a ground on the chassis. I'd check for resistance across the engine harness wire. I'd put dielectric grease in the plugs of the sensor, sub-harness and harness, but not at the ECU. I'd be ready to buy a new sensor and install it. You are close. You must be. It nearly passed itself, then it forgot and failed itself.

Hmm, along this train of thought is the why?. Did this have anything to do with warm up? I mean a switch from cold start operation to normal temp operation? I think knock is ignored during cold routine, so... if you started and stopped and started and stopped your car a few times in a row, never getting up to operating temperature each time, then the computer had enough restarts without a triggered knock and tossed the code aside. It doesn't store them forever. Then, you finally get it up to normal operating temperature for test day and it finally looks at the sensor again and fails. Just a thought.

I guess you have a registration sticker issue. I wish you could do the above and then drive it around a while to make sure the code isn't returning, then take it to smog. Backroads at night maybe?

I was wondering about that ECM location that you had mentioned, now your response makes sense. Sooo do I have to cut that checkered plastic cover off the ECM where all the wires are going into the ECM or does it just unclip or ?? I will tie into that tomorrow morning and back-probe the voltage at that # 64 plug with the key on and sub-harness disconnected. I will go ground to theECM ground or somewhere close by. IF that shows 5 volts output I will have to start tracking down where the voltage drop between the ECM and the sub-harness terminal is occurring.

IF there is 3.34 volts coming out of the #64 terminal I think I'll be going to Autozone tomorrow and getting a new knock sensor and installing it. I hate to be a parts changer but it keeps coming back to that part. I sure wish someone here could confirm/deny the 5 volt input to the knock sensor theory. Then I would possibly know if the 3.34 voltage incoming to the knock sensor is possibly part of the issue!!?????

Re: 1999 Maxima Knock Sensor Input Voltage Question

In doing further research I ran across this unfortunate bit of information relating to what I'm up against;

http://maxima.org/forums/4th-generation ... ost8874437

In this thread, if you start from the OP, there is talk of folks running a separate wire to bypass the damaged wire in the wire harness.......thoughts??

I attempted to search for TSB's here on this site, I must have not done it correctly as I couldn't find a location for them. I went out on-line and found a site where I could print out directly without having to do any hincky signup stuff. Here is a link to that site for printable access of the TSB;

http://www.readbag.com/lyberty-car-maxi ... ntb98-008b

The above information was sourced here;Nissan's National Technical Bulletin NTB98-008b dated September 16, 1999 addresses 1995-1999 Maxima EGI harness wire breakage diagnosis and repair procedures. The main wiring harness from the ECU/ECM goes thru the firewall and comes up near the right strut tower. Down low, just in front of the firewall some of the wires make a sharp bend at a "T" in the line and apparently Nissan has experienced quite a few breaks in one or more of the signal wires there.

The KS wire is a 'shielded' wire which means it has an interference grounding shield around the signal wire to preclude a signal from an adjacent wire being induced into the KS's signal wire. The shielding should be essentially grounded at each end. The signal wire can either part (break) from continuous vibration at the sharp turn in the harness or the insulation can break and allow the signal conductor to 'ground' out against the shielding, either case causing problems. If the signal wire is just 'broken', you will get no continuity, and/or resistance will be essentially infinite. Check out the Service Bulletin (sorry I can't tell you exactly where to find it right now, but should be easy to 'search' out) and it outlines diagnostic procedures.

http://maxima.org/forums/4th-generation ... ost8874437

In this thread, if you start from the OP, there is talk of folks running a separate wire to bypass the damaged wire in the wire harness.......thoughts??

I attempted to search for TSB's here on this site, I must have not done it correctly as I couldn't find a location for them. I went out on-line and found a site where I could print out directly without having to do any hincky signup stuff. Here is a link to that site for printable access of the TSB;

http://www.readbag.com/lyberty-car-maxi ... ntb98-008b

- centralcoaster33

- Posts: 2769

- Joined: Tue Apr 05, 2005 10:41 am

- Car: 240SX #5-1997

- Location: Central Coast, CA

Re: 1999 Maxima Knock Sensor Input Voltage Question

Well, if you get around to testing the continuity and resistance of the harness wire for the knock sensor to ECU, you might find it's a bad wire, shorted or something. You can bypass the one wire and I think you'd be set. You could use a regular wire I figure. A shielded wire would be a bit more work. I'd bypass the length of it all to be done with it. Just the core wire, not the ground and stuff (unless you go the shielded route). I'd leave all the ground and shield and old wire in place and only disconnect the ends of the center wire to put in your replacement wire (hopefully that makes sense). You could run it parallel to the engine harness wire and pop it through your firewall wherever you see fit (small hole through a rubber grommet maybe) and then tape it off to the harness. That TSB has you replacing the broken part in the bend... looks like a PITA and what if there were more failure points than just that bend?

PS the bad wire makes sense. Intermittent CEL or success. Good voltage, then bad reading... probably why the FSM says to test continuity across the harness wire. So take off that plastic cover and get to the back of your ECU wires. It will snap out of the plug part somehow.

PS the bad wire makes sense. Intermittent CEL or success. Good voltage, then bad reading... probably why the FSM says to test continuity across the harness wire. So take off that plastic cover and get to the back of your ECU wires. It will snap out of the plug part somehow.

Re: 1999 Maxima Knock Sensor Input Voltage Question

Thank you for your confirmation of the path I've decided to go down......hopefully tomorrow!??centralcoaster33 wrote:Well, if you get around to testing the continuity and resistance of the harness wire for the knock sensor to ECU, you might find it's a bad wire, shorted or something. You can bypass the one wire and I think you'd be set. You could use a regular wire I figure. A shielded wire would be a bit more work. I'd bypass the length of it all to be done with it. Just the core wire, not the ground and stuff (unless you go the shielded route). I'd leave all the ground and shield and old wire in place and only disconnect the ends of the center wire to put in your replacement wire (hopefully that makes sense). You could run it parallel to the engine harness wire and pop it through your firewall wherever you see fit (small hole through a rubber grommet maybe) and then tape it off to the harness. That TSB has you replacing the broken part in the bend... looks like a PITA and what if there were more failure points than just that bend?

PS the bad wire makes sense. Intermittent CEL or success. Good voltage, then bad reading... probably why the FSM says to test continuity across the harness wire. So take off that plastic cover and get to the back of your ECU wires. It will snap out of the plug part somehow.

My plan is to remove the ECM junction plug and see if that clear plastic cover over the plug is easily un-fastened and go searching for the #64 wire. After I find that wire I am going to back probe it to see what the voltage is coming out of the ECM. If it's 3.34 volts I'll be stymied as to where to go from there.........I'm still under the impression that the knock sensor should have 5 volts going to it!!??? Sure wish someone that has the technical knowledge could confirm or disprove that.

- WDRacing

- Moderator

- Posts: 23925

- Joined: Mon Nov 25, 2002 2:00 am

- Car: 95 240SX, 99 BMW 540i, 01 Chevy Express, 14 Ford Escape

- Location: MFFO

- Contact:

Re: 1999 Maxima Knock Sensor Input Voltage Question

Just a thought...have you considered wiring a resistor to the ecu side of the knock sensor plug, possibly at the sub harness? They are cheap and fairly easy to temp install, pass your test and uninstall.

After a ton of reading I've found that many people with Nissans are only getting 3.XXX volts on the knock sensor output from the ECU. If the wire ohms out good the fix is always a new sensor.

I'm pretty sure this is the resistor you need to use. This will remove the knock sensor as well as it's safety function. So if your motor is knocking and the sensor is only doing it's job then you could possibly damage your motor if detonation becomes severe enough.

https://www.radioshack.com/products/rad ... 5717284165

I use an OBDII Adapter called the ELM 327. It see's everything the ECU sees and you can customize what parameters you want to look at. You can even datalog them.

https://smile.amazon.com/Professional-D ... ds=elm+327

It connects to my tablet or phone via Bluetooth. I use the Torque app to view all the data it receives. On my BMW I can view real time data like timing advance, coolant temp etc. It also senses knock. It's probably the most used tool I have in my inventory now and it's ridiculously cheap. It resets codes as well. I suggest everyone own one or something similar.

After a ton of reading I've found that many people with Nissans are only getting 3.XXX volts on the knock sensor output from the ECU. If the wire ohms out good the fix is always a new sensor.

I'm pretty sure this is the resistor you need to use. This will remove the knock sensor as well as it's safety function. So if your motor is knocking and the sensor is only doing it's job then you could possibly damage your motor if detonation becomes severe enough.

https://www.radioshack.com/products/rad ... 5717284165

I use an OBDII Adapter called the ELM 327. It see's everything the ECU sees and you can customize what parameters you want to look at. You can even datalog them.

https://smile.amazon.com/Professional-D ... ds=elm+327

It connects to my tablet or phone via Bluetooth. I use the Torque app to view all the data it receives. On my BMW I can view real time data like timing advance, coolant temp etc. It also senses knock. It's probably the most used tool I have in my inventory now and it's ridiculously cheap. It resets codes as well. I suggest everyone own one or something similar.

- WDRacing

- Moderator

- Posts: 23925

- Joined: Mon Nov 25, 2002 2:00 am

- Car: 95 240SX, 99 BMW 540i, 01 Chevy Express, 14 Ford Escape

- Location: MFFO

- Contact:

Re: 1999 Maxima Knock Sensor Input Voltage Question

Here's our article on the OBDII adapters.

http://www.nicoclub.com/archives/wirele ... t-one.html

http://www.nicoclub.com/archives/wirele ... t-one.html

Re: 1999 Maxima Knock Sensor Input Voltage Question

Thank you for your input on the 3.XXX volts on the knock sensor output from the ECM. I wish there were a reference to that voltage value in the FSM somewhere.WDRacing wrote:Just a thought...have you considered wiring a resistor to the ecu side of the knock sensor plug, possibly at the sub harness? They are cheap and fairly easy to temp install, pass your test and uninstall.

After a ton of reading I've found that many people with Nissans are only getting 3.XXX volts on the knock sensor output from the ECU. If the wire ohms out good the fix is always a new sensor.

I'm pretty sure this is the resistor you need to use. This will remove the knock sensor as well as it's safety function. So if your motor is knocking and the sensor is only doing it's job then you could possibly damage your motor if detonation becomes severe enough.

https://www.radioshack.com/products/rad ... 5717284165

I use an OBDII Adapter called the ELM 327. It see's everything the ECU sees and you can customize what parameters you want to look at. You can even datalog them.

https://smile.amazon.com/Professional-D ... ds=elm+327

It connects to my tablet or phone via Bluetooth. I use the Torque app to view all the data it receives. On my BMW I can view real time data like timing advance, coolant temp etc. It also senses knock. It's probably the most used tool I have in my inventory now and it's ridiculously cheap. It resets codes as well. I suggest everyone own one or something similar.

Interesting that you posted up the RS picture of the resistor that I picked up last night at one of the few remaining RS's in the Phoenix metro area. They came in a 5 pack so I've got enough to attempt a resistor grounding of KS circuit......so yes, I've considered it and will probably try that first, going off of your reference to the ECM knock sensor output voltage.

Regarding the ELM 327 recomendation, it sounds like an excellent diagnostics tool for a very minimal investment, thanks for the tip on that!!

- centralcoaster33

- Posts: 2769

- Joined: Tue Apr 05, 2005 10:41 am

- Car: 240SX #5-1997

- Location: Central Coast, CA

Re: 1999 Maxima Knock Sensor Input Voltage Question

I would only put the resistor in if my sensor was bad and I couldn't afford to replace it. A sort of ghetto fix. I think you're sensor is good and you have a bad wire (per your Ohm test). I'd bypass the wire. It's just as much work (actually, possibly less work) than putting a resistor in. Plus it results in you having an actual, functional knock sensor. The wire bypass is so easy that after all of your efforts, I think I'd pretty much go straight to putting that wire in. Then driving a bit and watching the code go away. IMHO.

You can still test the pin for voltage without the scanner tool. You'll already be in there for access to the wires to put on the bypass wire.

You can still put that resistor on if the bypass wire isn't working out and maybe the extra bypass wire will make it easier to solder the ends.

You can still test the pin for voltage without the scanner tool. You'll already be in there for access to the wires to put on the bypass wire.

You can still put that resistor on if the bypass wire isn't working out and maybe the extra bypass wire will make it easier to solder the ends.

Re: 1999 Maxima Knock Sensor Input Voltage Question

WDRacing wrote:Just a thought...have you considered wiring a resistor to the ecu side of the knock sensor plug, possibly at the sub harness? They are cheap and fairly easy to temp install, pass your test and uninstall.

After a ton of reading I've found that many people with Nissans are only getting 3.XXX volts on the knock sensor output from the ECU. If the wire ohms out good the fix is always a new sensor.

XPLRN wrote: Interesting that you posted up the RS picture of the resistor that I picked up last night at one of the few remaining RS's in the Phoenix metro area. They came in a 5 pack so I've got enough to attempt a resistor grounding of KS circuit......so yes, I've considered it and will probably try that first, going off of your reference to the ECM knock sensor output voltage.

I do appreciate everyone's input as this has been one of the most trying automotive emissions requirement scenarios I've encountered..........to date!! It was a busy day today and I had a tiny window of opportunity to take some action when I finally got home. The action I chose to take was installing the 470K Ohm resistor, as pictured in 'WDRacing's post. I figured it was the quickest/easiest change to make and it had been referenced by folks here and other places. I'm happy to report, 'centralcoaster33', that it took me less than 10 minutes to install that resistor and that included looking around for some tape. I think that digging into that ECM terminal, splicing in a wire and routing it out to KS sub harness terminal in the engine compartment would have taken **a lot** longer than that!???centralcoaster33 wrote:I would only put the resistor in if my sensor was bad and I couldn't afford to replace it. A sort of ghetto fix. I think you're sensor is good and you have a bad wire (per your Ohm test). I'd bypass the wire. It's just as much work (actually, possibly less work) than putting a resistor in. Plus it results in you having an actual, functional knock sensor. The wire bypass is so easy that after all of your efforts, I think I'd pretty much go straight to putting that wire in. Then driving a bit and watching the code go away. IMHO.

You can still test the pin for voltage without the scanner tool. You'll already be in there for access to the wires to put on the bypass wire.

You can still put that resistor on if the bypass wire isn't working out and maybe the extra bypass wire will make it easier to solder the ends.

The great news is....................the resistor seems to have done the trick!!! Even though the knock sensor ohm'ed out correctly there must be something that is not right about it. Doing the resistor install was the **only** thing I did......I did not remove the ECM terminal/wire bundle and I did not ohm out/continuity test the #64 wire from the ECM to the knock sensor.

I know it was a "ghetto" fix but right now the very most important thing is getting that vehicle thru emissions and re-registered!! During the 80-ish miles I drove tonight it the green light(indicator that it will pass emissions) on the Innova 3120 tester has came on every time I tested it, 4 times in the course of that trip. Tomorrow, my special B-day(born in '58 and will be 58), I should be able to get it thru emissions if I get back in time......emissions is open until 7pm. We've got a slammin' busy day tomorrow moving everything from a 8000 lb. CNC lathe machining center, a gun safe, a 8-foot brake and if enough gets done in the AM possibly a trip to Prescott to bring another 8000 lb. lathe machining center back to Phoenix!!

I'll hook up the Innova 3120 after I drive to work tomorrow morning and will be keeping my fingers crossed that the green light comes on again after that 5-6 mile trip!!!

- WDRacing

- Moderator

- Posts: 23925

- Joined: Mon Nov 25, 2002 2:00 am

- Car: 95 240SX, 99 BMW 540i, 01 Chevy Express, 14 Ford Escape

- Location: MFFO

- Contact:

Re: 1999 Maxima Knock Sensor Input Voltage Question

The torque app doesn't display the actual voltage of the knock detected, only that it is being detected. I haven't had any register so I can't say for sure if it displays the severity of the knock, or just that some has occurred. The Torque app is awesome in general though. I use it often.XPLRN wrote: Does it, or the Torque app that it's feeding the data to, to have the capability to read/monitor the real time voltage on the #64 pin of the ECM(the KS circuit) as that would answer the voltage question ?? I'm very curious how it senses knock and then displays that information in the 'Torque' app?? I'm presuming that you sprung for the 'Torque' Pro version?? The positive thing regarding the ELM 327 is that I am a Android phone user so that's a plus to know that the ELM 327 will function with my phone......now off to get the 'Torque' app!!

Just for safety I suggest running the highest octane available in your area to avoid knock. 87 on a hot day under a heavy load could cause some knock to occur.

Glad to help you get registered!

Re: 1999 Maxima Knock Sensor Input Voltage Question

Thanks, again, to all that contributed ideas and suggestions!! The 1999 Maxima went right thru emissions this afternoon with no problem and the vehicle is re-registered. I am so very happy to have this saga behind me!!!

Thank you, WDRacing, for the Torque app tip and relating info about the app. I have been running the 'premium' gas for some time now and will continue to do so since my knock sensor is disconnected currently with the resistor in place.

I had bought the 10-12 dollar Amazon knock sensor but it didn't ohm out.....at all. Any suggestions on where to buy a functional/quality knock sensor for a reasonable price??

Thank you, WDRacing, for the Torque app tip and relating info about the app. I have been running the 'premium' gas for some time now and will continue to do so since my knock sensor is disconnected currently with the resistor in place.

I had bought the 10-12 dollar Amazon knock sensor but it didn't ohm out.....at all. Any suggestions on where to buy a functional/quality knock sensor for a reasonable price??

- WDRacing

- Moderator

- Posts: 23925

- Joined: Mon Nov 25, 2002 2:00 am

- Car: 95 240SX, 99 BMW 540i, 01 Chevy Express, 14 Ford Escape

- Location: MFFO

- Contact:

Re: 1999 Maxima Knock Sensor Input Voltage Question

http://www.buyautoparts.com/buynow/1999 ... ref=237280

I replaced all the coil packs, front suspension, control arms and MAF on my BMW and the MAF on my 240SX with their stuff. No issues thus far.

Advance Auto has them for about the same price. I use both places often.

I replaced all the coil packs, front suspension, control arms and MAF on my BMW and the MAF on my 240SX with their stuff. No issues thus far.

Advance Auto has them for about the same price. I use both places often.

- centralcoaster33

- Posts: 2769

- Joined: Tue Apr 05, 2005 10:41 am

- Car: 240SX #5-1997

- Location: Central Coast, CA

Re: 1999 Maxima Knock Sensor Input Voltage Question

Yay! I'm glad you passed Smog. It's going to be nice to be able to just get back to driving and normal life (not stressing on gov't requirements).

I wouldn't have been able to do anything in just 10 minutes (it takes me that long just to get out and warm up my soldering iron). I'm glad the resistor was so easy.

Maybe you can return that bunk sensor from Amazon.

I even learned some things in this thread. I wonder if I could use the torque app stuff if I didn't have a smart phone. I'll be looking into that.

I wouldn't have been able to do anything in just 10 minutes (it takes me that long just to get out and warm up my soldering iron). I'm glad the resistor was so easy.

Maybe you can return that bunk sensor from Amazon.

I even learned some things in this thread. I wonder if I could use the torque app stuff if I didn't have a smart phone. I'll be looking into that.

Re: 1999 Maxima Knock Sensor Input Voltage Question

Thank you, 'WDRacing' for the parts sourcing info, I'll certainly reference them in the future!! Regarding coil packs for the 1999 Maxima I learned that replacement ones have to be OEM as the aftermarket ones don't seem to satisfy the ECM's electronic parameters. The ECM will still throw the code for a bad coil pack even if the aftermarket one was firing the cylinder....something to do with impedence or !!???? Don't know why that is but something I ran into early on after buying an aftermarket coil pack and finding out that the ECM wasn't liking it.WDRacing wrote:http://www.buyautoparts.com/buynow/1999 ... ref=237280

I replaced all the coil packs, front suspension, control arms and MAF on my BMW and the MAF on my 240SX with their stuff. No issues thus far.

Advance Auto has them for about the same price. I use both places often.

Thank you, 'centralcoaster33' for your support/input into this saga. Yes, I'm very happy to gotten the emissions requirement taken care of and the car re-registered for another two years!!!centralcoaster33 wrote:Yay! I'm glad you passed Smog. It's going to be nice to be able to just get back to driving and normal life (not stressing on gov't requirements).

I wouldn't have been able to do anything in just 10 minutes (it takes me that long just to get out and warm up my soldering iron). I'm glad the resistor was so easy.

Maybe you can return that bunk sensor from Amazon.

I even learned some things in this thread. I wonder if I could use the torque app stuff if I didn't have a smart phone. I'll be looking into that.

I bet you could have done what I did in 10 minutes also!! I took one end of the resistor and bent it over tight against it's self to provide more engagement into the female end of the knock sensor sub-harness terminal(the one with the 3.34 volts). I then wrapped a bit of tape around that to keep engine vibration from possibly affecting the engagement. The wire diameter of the resistor (I had double width of it since I bent it over) fit pretty snug into the female terminal. I then bent a 'U' shape into the other end of the resistor and loosened up some senor(10 mm wrench) that was close by and hooked that 'U' end under that bolt and tightened it down providing the path to ground. It really didn't take much effort and no soldering!!

I'm thinking about doing a Amazon return but is the effort worth it?? They actually messed up in the order picking and sent me two of the knock sensors........I might dissect one of them to see exactly what's inside!!

I'm pretty sure the 'Torque' app is designed for Android based cell phone usage......luckily that is what I have (LG G3) and I **will** have that OBDII adapter that 'WDRacing' shared about; http://www.nicoclub.com/archives/wirele ... t-one.html sometime in the near future!!