I have a couple updates this time around.

Part 1:

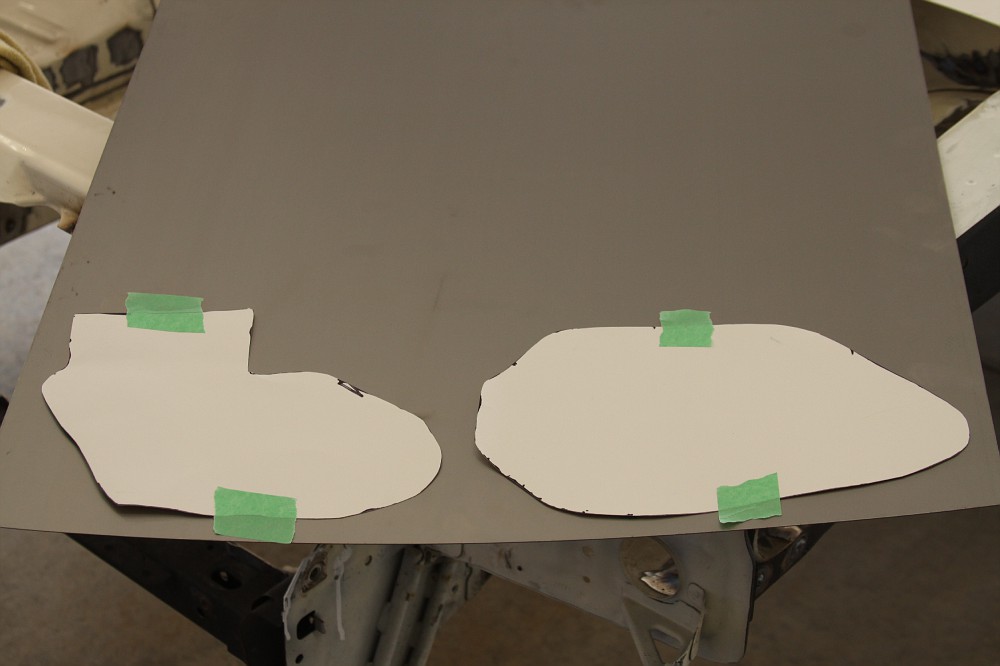

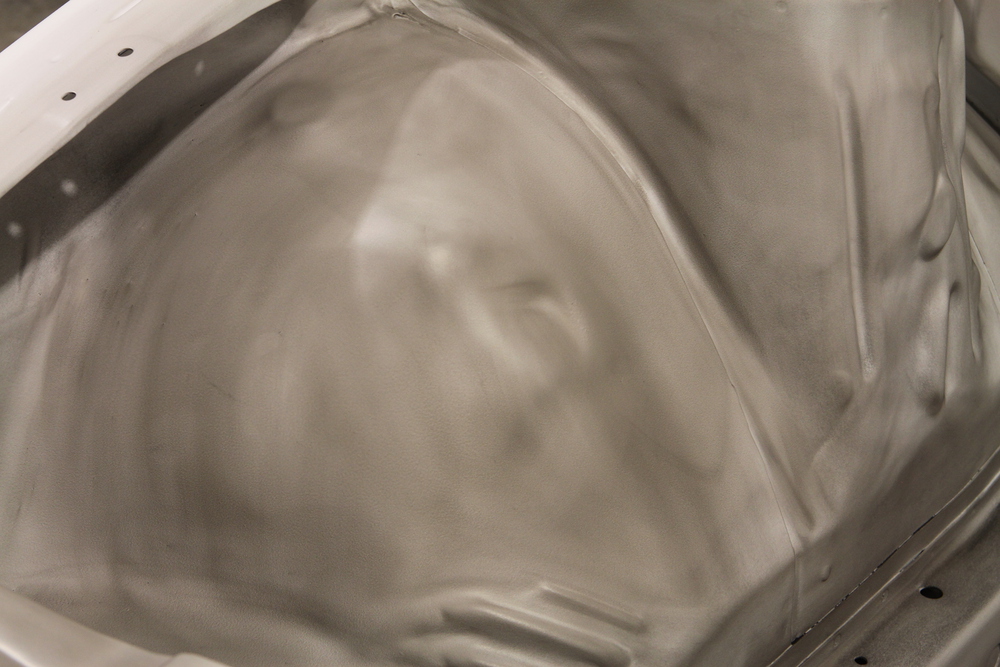

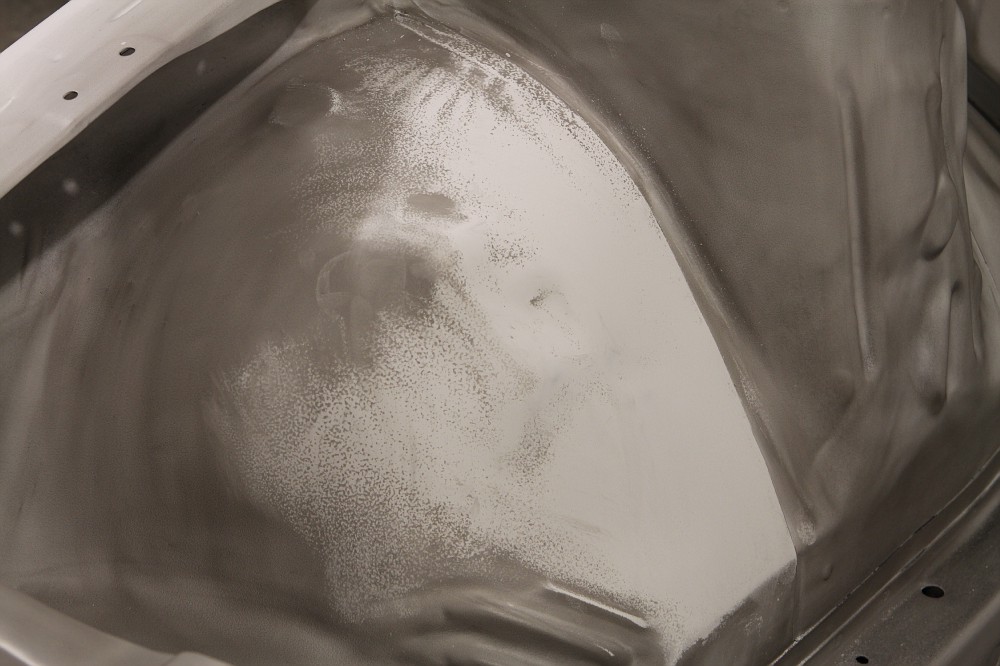

Continuing on the bay, I blocked down the body filler in front of the tubs on each side:

I then skim coated that area with some Evercoat Metal Glaze to fill in any remaining imperfections, pinholes and the like. Blocked that down then sprayed the area with etch primer to properly seal all of the bare metal. It's nice to finally be able to get an idea of what the bay is going to look like. Keep in mind, my goal was never to make this a completely smoothed/shaved bay. I simply wanted to fill all of the holes and remove any brackets etc. I absolutely want it to still look like an engine bay with all of the weird metal undulations etc. I just didn't want it to look like a motor sitting in a perfectly smoothed bathtub... it's not a show car.

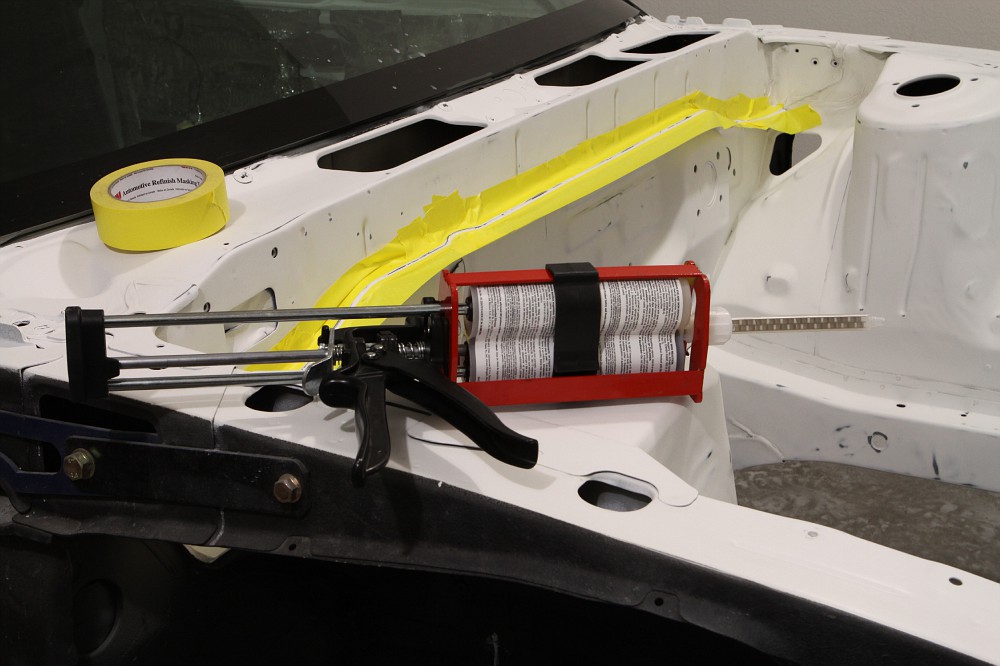

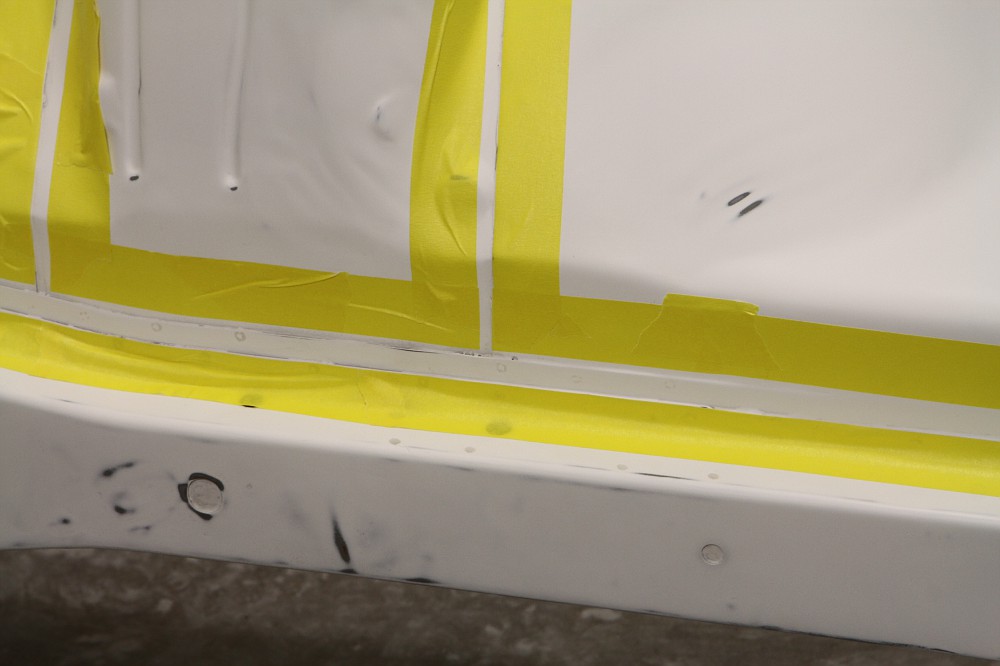

Now I'm at the point of going back and addressing little areas... making sure everything is up to standards before I primer it. I will be using 4 coats of white primer on this. I also need to reapply seam sealer to all of the OEM locations that originally had it before I primer it.

Part 2:

I finally received all of my Sikky product yesterday. As mentioned earlier in this thread, Sikky was nice enough to give me a partial sponsorship. Even with that, it took me a few months to save up the dough to get it here. In trade for the hook up, I agreed to give my honest opinion on the product and dole out several write-ups on installation, performance and so on. I will start off by saying that they have been nothing short of perfection in the customer service area. I have been dealing with Justin over there and have had zero complaints!

Onto the product... I want to post a couple pictures of each product to start off with. I'm sure most have seen this stuff several times, but this will be a good thread to see multiple pictures of the product, on and off the vehicle/motor.

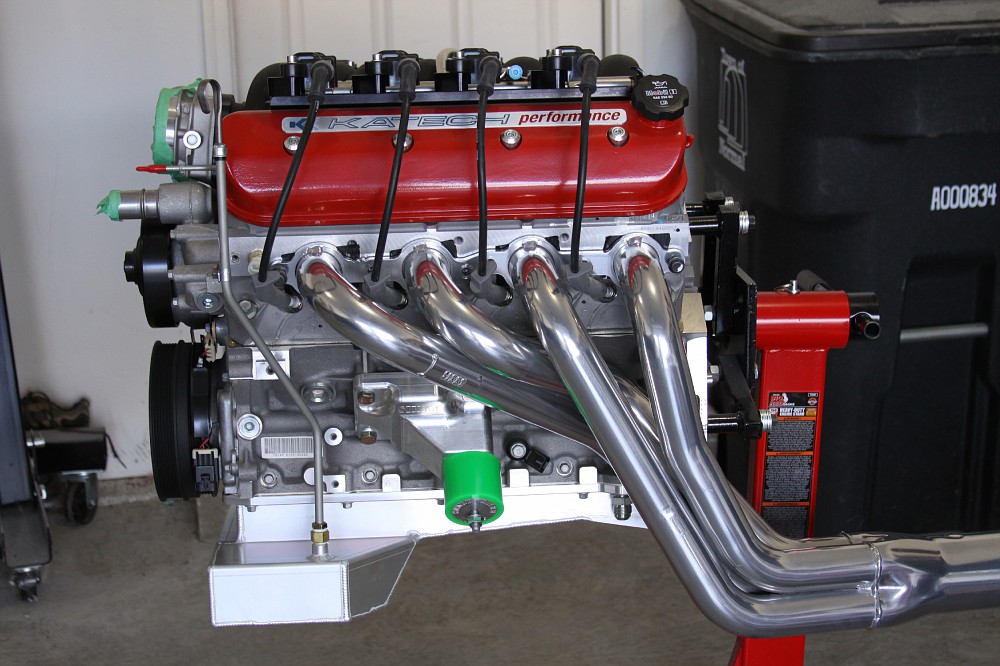

Sikky Headers: I went with the 1-7/8" primaries since I plan on over 500whp and eventually more down the road. I opted for the coated ones. I went ahead and mounted one up because I wanted to check for fitment and clearance issues... all is good!

I knew it would be VERY tight at the bottom back of the motor where the bell housing bolts up. I just assumed I would have to shave that corner of the block just to get them to fit, but they actually fit. There is about 2mm of clearance... which I will be shaving that corner off just to make sure there is no rubbing issues at any point.

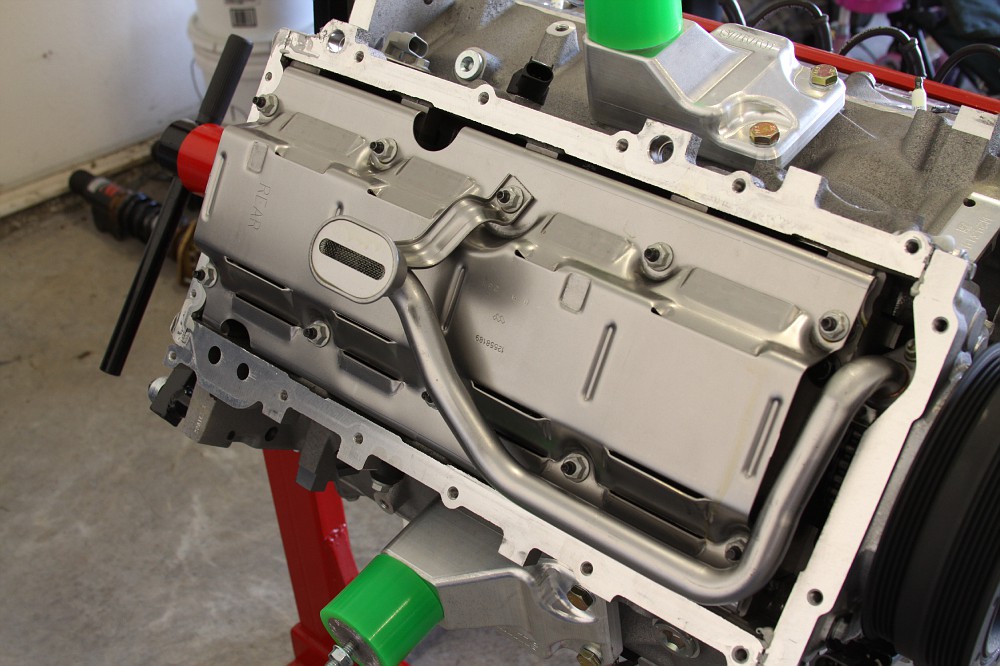

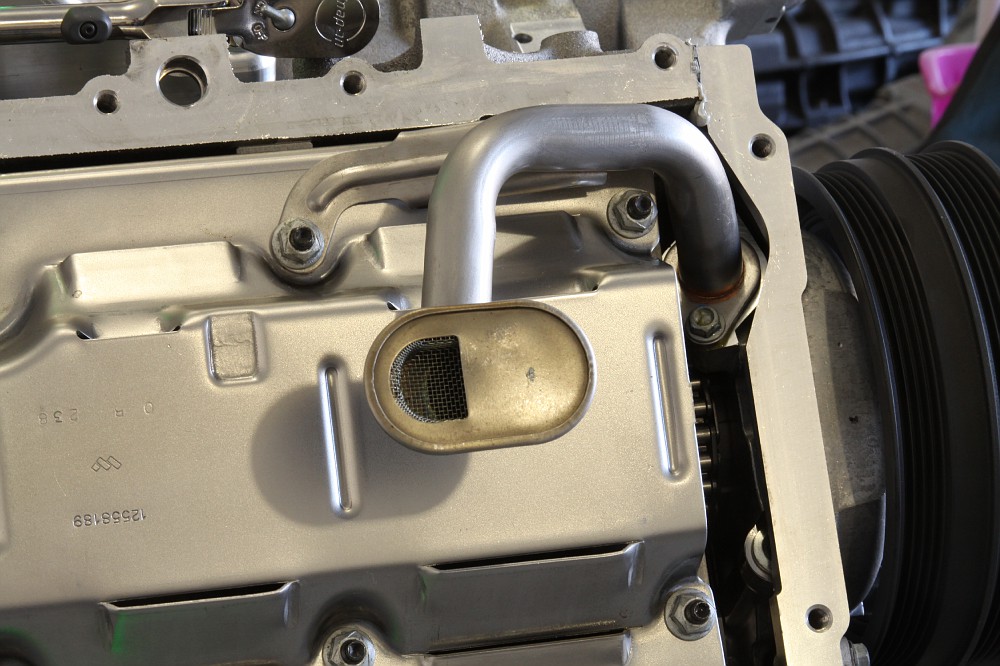

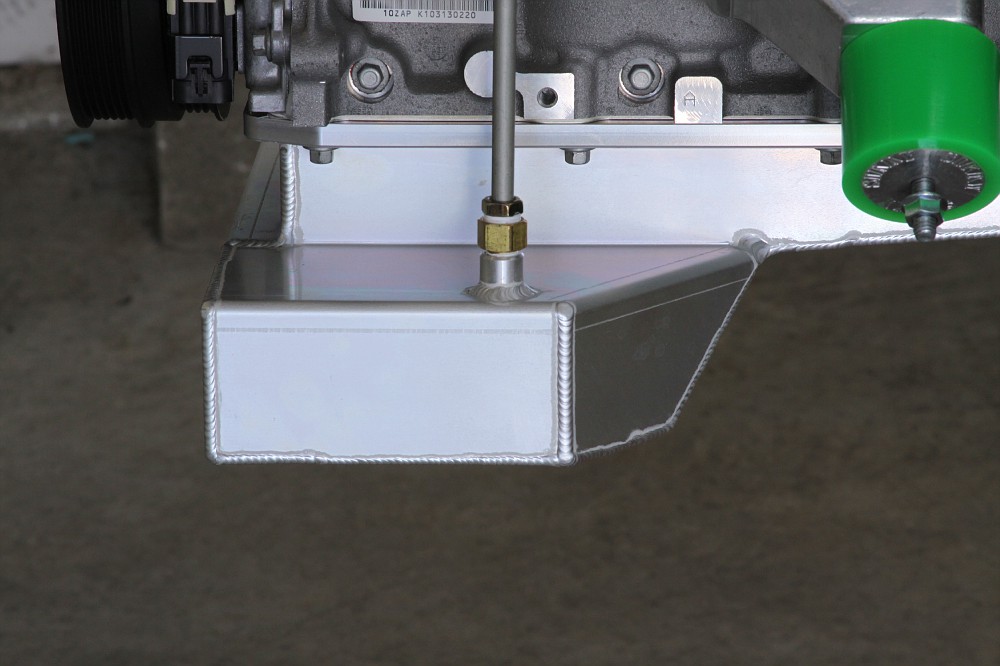

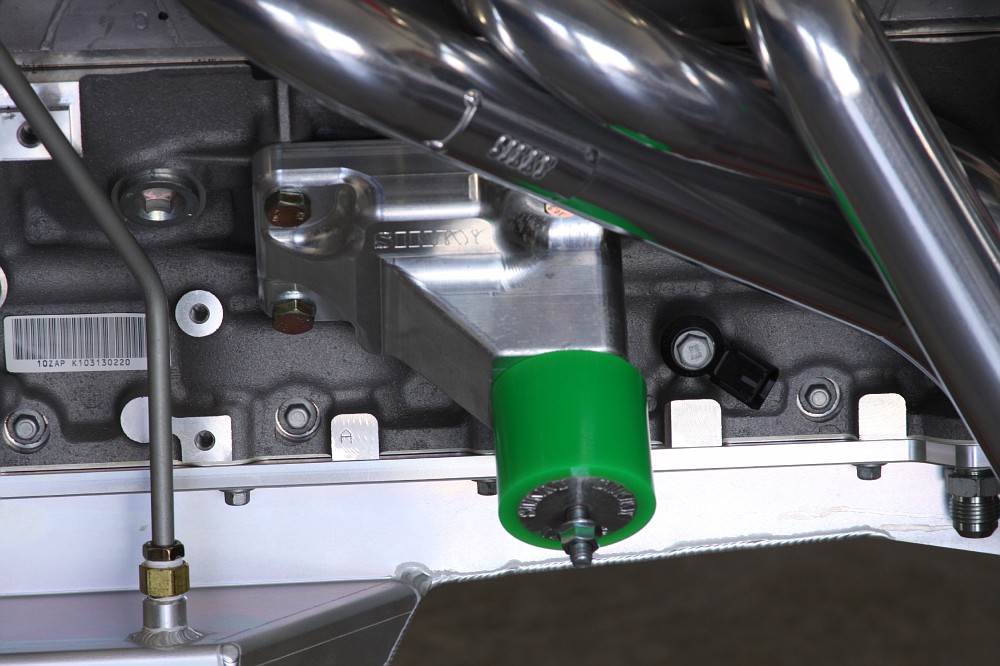

Sikky Oil Pan Kit:

Sikky Oil Pan Kit: Very nice craftsmanship! The kit includes a new oil pickup, new oil dip stick, tube and bung, new OEM gasket and new oil filter relocation setup. Everything seems to be really well thought out. The new location for the oil dip stick is also baffled on the inside... little things like that were not overlooked.

I probably won't be utilizing the Sikky oil filter relocation. While I'm sure it will work just fine, I will want something a little more "baller" for this setup... something similar to what I had on my SR. Everything in the bay will be braided nylon AN lines anyway, so I would hate to have some stainless lines just chill'n in the bay all by themselves. You never know though, I may use it temporarily just to get it fired up.

Sikky LS Motor Mounts: Not much to say, they are a solid hunk of metal that looks tits. As long as they line up and don't break down the road then I guess they'll work just fine. They also make a solid mount option, which I obviously opted not to go with.

Sikky Master Cylinder Conversion Kit:

Sikky Master Cylinder Conversion Kit: Utilizes a Wilwood master cylinder(which I'll be coating black to match my Wilwood brake master cylinder) and Sikky's CNC'd mount for an effortless install onto the firewall. Lines are also included.

Sikky Driveshaft:

Sikky Driveshaft: I went with the aluminum option... they also make a steal version. They have them for S13, S14, with or without ABS.

Sikky Subframe Bushings:

Sikky Subframe Bushings:

The transmission subframe is also included in this kit, but it is on backorder... should have that sooner than later. With the extended weekend, I'm hoping to get the pan on and work on the bay a little more. I promised a lot of my time to the family though, so we'll see how it goes. It is a 2-day weekend for me though, so I should have enough time to please everyone:D