how to supercharge a ca18det?

- float_6969

- Moderator

- Posts: 19857

- Joined: Mon Aug 26, 2002 1:55 pm

- Car: CA18DET swapped 1995 Nissan 240sx (too many mods to list)

2015 SV Leaf w/QC & Bose (daily) - Location: Topeka, Kansas

- Contact:

Re: how to supercharge a ca18det?

You'll want to get a header figured out for the exhaust if you really want to take advantage of this setup. Something in a 4-2-1 would be preferable, with 1-4 & 2-3 being paired

Re: how to supercharge a ca18det?

what's the benefit from that?

can't I use a stock ca18de exhaust manifold? or use a custom turbo exhaust manifold with the turbo outlet blocked off?

can't I use a stock ca18de exhaust manifold? or use a custom turbo exhaust manifold with the turbo outlet blocked off?

Re: how to supercharge a ca18det?

Hi people,

I've been pretty well googled as I can find some of my post referred to in this thread

This seems to be an interesting discussion about the basic considerations when making the choice SC vs turbo.

Which SC items are easily available is a point that to a large extent influences the choice of the SC. We'll have to do with what's around.

That's how I got started with this project. A friend came to me and asked Can you do something with a kompressor from a MB engine?

He knew that in such case I can not refuse. If tomorrow he pops up with an aircraft engine, next year it will have four wheels

During the years before I have been playing with turbo's and I am convinced that in a good designed setup they are very reliable and efficient.

In the field of pure physics they are more efficient than any SC but this is not what we care about. An OEM engineer wants to design an engine with low consumption, we want a powerful car with a specific character (read: torque graph).

Both turbo and SC have their specific influence on the way power is developed by the engine. It's all about compromise. We choose for the SC.

There are a couple of things mentioned in this thread to which I would like to add my 2p.

- There is no turbo lag with a SC. There is SC lag instead You can not deny the reaction times measured in my setup. I have a volume of roughly 10L between the SC and the intake valves. With an air/water IC integrated to the inlet plenum I guess you will noticeably decrease the lag effect caused. The same applies to a turbo setup but don't tell anybody, they all think it's turbo lag

You can not deny the reaction times measured in my setup. I have a volume of roughly 10L between the SC and the intake valves. With an air/water IC integrated to the inlet plenum I guess you will noticeably decrease the lag effect caused. The same applies to a turbo setup but don't tell anybody, they all think it's turbo lag

I used the electric bypass valve just because it was there and I found it a challenge. From open to close it takes 0.215sec. This adds to the other lag causes. I have no idea how a vacuum actuated valve performs but please let me know when you measured it

- One path I haven't seen here is to mount the SC under the inlet plenum. It's feasible if you move the alternator and the oil filter-heat exchanger combo. That is the way I want to go for my new setup.

- If you insist on keeping the A/C, keep in mind that this stresses the importance of the idle regulation AAC and FICD valves. This could get tricky when using custom plenums and/or installing the TB upstream of the SC.

- The bypass valve. The M62 mentioned has an electric clutch. I guess it should have somekind of a bypass as well because the engine will not be able to breath very well through the SC which is at standstill. I think that in this case it could be a non-return style valve which is rather simple in construction but mind you sometimes the more easy it looks, the more difficult it gets. If this valve is doing nothing more than opening with the flow and closing with the reverse pressure difference, the SC kick-in will be very noticeable. If you can live with that feeling, you could as well control the electric valve of the M45 with a switch or from a TPS threshold. That will be much more simple that my attempt to control the pressure build-up.

- If this http://victorylibrary.com/graphics/Eaton-M62-1.JPG is the M62 we're all talk about it seems to me that its pulley has a larger diameter than the one on the M45. You will need a larger diameter pulley on the crankshaft to make it spin as fast as the others then.

I know you don't need the M62 to spin as fast as the M45 to achieve the same mass flow but make sure you manage to get where you want.

- The crank pulley is one of the main issues. I've seen only one build of aftermarket pulley for the CA18DET and that was without torsional vibration damper.

On one of the boards someone was using an undamped aftermarket pulley. I can't find it right now but it would be useful to have feedback about this.

I'm using the stock pulley where the middle (A/C) disk has been removed with a lathe and a new steel disk pressed on with an interference fit of 0.04mm. For peace of mind I had it balanced after this.

Looks like this:

You can't go larger in outer diameter or the belt will touch the waterpump pulley.

James on the SXOC was so kind to donate a part of his body to science -corpus vivi- sacrificed a pulley and dissected it to reveal its secrets:

I'm using a CA18DET timing belt tensioner to tension the 5-rib SC belt. No noticeable slip nor signs of wear but who knows how long the belt will live.

It might look convenient to build a crankshaft pulley with the SC disc in front of the other ones but that will move forward the fulcrum point of the side force exerted on the pulley by the belt. If you see that there is only about 10mm of crankshaft for the pulley to sit on, I am not at all convinced that this is the way to go.

Cheers,

Jean

I've been pretty well googled as I can find some of my post referred to in this thread

This seems to be an interesting discussion about the basic considerations when making the choice SC vs turbo.

Which SC items are easily available is a point that to a large extent influences the choice of the SC. We'll have to do with what's around.

That's how I got started with this project. A friend came to me and asked Can you do something with a kompressor from a MB engine?

He knew that in such case I can not refuse. If tomorrow he pops up with an aircraft engine, next year it will have four wheels

During the years before I have been playing with turbo's and I am convinced that in a good designed setup they are very reliable and efficient.

In the field of pure physics they are more efficient than any SC but this is not what we care about. An OEM engineer wants to design an engine with low consumption, we want a powerful car with a specific character (read: torque graph).

Both turbo and SC have their specific influence on the way power is developed by the engine. It's all about compromise. We choose for the SC.

There are a couple of things mentioned in this thread to which I would like to add my 2p.

- There is no turbo lag with a SC. There is SC lag instead

I used the electric bypass valve just because it was there and I found it a challenge. From open to close it takes 0.215sec. This adds to the other lag causes. I have no idea how a vacuum actuated valve performs but please let me know when you measured it

- One path I haven't seen here is to mount the SC under the inlet plenum. It's feasible if you move the alternator and the oil filter-heat exchanger combo. That is the way I want to go for my new setup.

- If you insist on keeping the A/C, keep in mind that this stresses the importance of the idle regulation AAC and FICD valves. This could get tricky when using custom plenums and/or installing the TB upstream of the SC.

- The bypass valve. The M62 mentioned has an electric clutch. I guess it should have somekind of a bypass as well because the engine will not be able to breath very well through the SC which is at standstill. I think that in this case it could be a non-return style valve which is rather simple in construction but mind you sometimes the more easy it looks, the more difficult it gets. If this valve is doing nothing more than opening with the flow and closing with the reverse pressure difference, the SC kick-in will be very noticeable. If you can live with that feeling, you could as well control the electric valve of the M45 with a switch or from a TPS threshold. That will be much more simple that my attempt to control the pressure build-up.

- If this http://victorylibrary.com/graphics/Eaton-M62-1.JPG is the M62 we're all talk about it seems to me that its pulley has a larger diameter than the one on the M45. You will need a larger diameter pulley on the crankshaft to make it spin as fast as the others then.

I know you don't need the M62 to spin as fast as the M45 to achieve the same mass flow but make sure you manage to get where you want.

- The crank pulley is one of the main issues. I've seen only one build of aftermarket pulley for the CA18DET and that was without torsional vibration damper.

On one of the boards someone was using an undamped aftermarket pulley. I can't find it right now but it would be useful to have feedback about this.

I'm using the stock pulley where the middle (A/C) disk has been removed with a lathe and a new steel disk pressed on with an interference fit of 0.04mm. For peace of mind I had it balanced after this.

Looks like this:

You can't go larger in outer diameter or the belt will touch the waterpump pulley.

James on the SXOC was so kind to donate a part of his body to science -corpus vivi- sacrificed a pulley and dissected it to reveal its secrets:

I'm using a CA18DET timing belt tensioner to tension the 5-rib SC belt. No noticeable slip nor signs of wear but who knows how long the belt will live.

It might look convenient to build a crankshaft pulley with the SC disc in front of the other ones but that will move forward the fulcrum point of the side force exerted on the pulley by the belt. If you see that there is only about 10mm of crankshaft for the pulley to sit on, I am not at all convinced that this is the way to go.

Sounds good. Can you post a picture of this?float_6969 wrote: I have a Ross Race balancer, so I have bolts right on the front that would allow me to mount a pulley easily.

Cheers,

Jean

- float_6969

- Moderator

- Posts: 19857

- Joined: Mon Aug 26, 2002 1:55 pm

- Car: CA18DET swapped 1995 Nissan 240sx (too many mods to list)

2015 SV Leaf w/QC & Bose (daily) - Location: Topeka, Kansas

- Contact:

Re: how to supercharge a ca18det?

Jean, thanks for dropping by and posting more useful info on the subject

as for me, I'm currently reading the Supercharged book...

also I found the Ross balancers here - http://www.enjukuracing.com/nissan-ca18 ... dbc6f333bf

currently I'm reading the Supercharged! book and will address on this topic when I will be feeling more confident knowledge-wise

as for me, I'm currently reading the Supercharged book...

also I found the Ross balancers here - http://www.enjukuracing.com/nissan-ca18 ... dbc6f333bf

currently I'm reading the Supercharged! book and will address on this topic when I will be feeling more confident knowledge-wise

Re: how to supercharge a ca18det?

looking for an xterra/frontier supercharger in good condition for 100-160 bucks + s/h. maybe someone has an extra piece laying around?

-

boost_boy

- Posts: 7162

- Joined: Thu Nov 14, 2002 7:28 am

- Car: B12 sentra w/built CA18DET, B12 sentra w/fully-built CA18DET, S13 coupe w/ CA18DET, S13 hatch w/CA18DET, 2002 maxima SE

- Location: Miami, FL.

- Contact:

Re: how to supercharge a ca18det?

For the amount of headaches and heartaches you will incur trying to make this happen, albeit not impossible, you can get just as much power and response if you set your engine up right with the correct turbocharger to suit your needs. Even with my GT35R, the response is still well within what one might think is the sweet spot for the CA to achieve wicked power. Again, setting it all up right via a good engine management system or chip or whatever device you need to tune with, will substantially increase the performance of your set-up; especially in the areas that you set it up to perform best in (ie down low, mid range, top end).

Re: how to supercharge a ca18det?

Dee, thank you for your reply. Engine management will be MegaSquirt-I. I do realize this won't be a power monster. However I don't have any cash for a new turbo (don't want to settle with a used unit) and I can always go back to my ol' rb20 turbo. I want to take on this project because it seems interesting to me.

btw, this guy showed that it can be done very cheap http://nissan.240sx.net/viewtopic.php?f ... &start=300 I believe the same approach can be used for the CA18.

I keep toying around with this idea from time to time, IMO should mount the s/c via an adapter plate to the lower intake manifold part (where the injectors + thermostat sits) and running it off the alternator belt. yeah, no intercooler for now, but can always integrate it later.

any comments, suggestions? (besides dropping it and going turbo? )

)

btw, this guy showed that it can be done very cheap http://nissan.240sx.net/viewtopic.php?f ... &start=300 I believe the same approach can be used for the CA18.

I keep toying around with this idea from time to time, IMO should mount the s/c via an adapter plate to the lower intake manifold part (where the injectors + thermostat sits) and running it off the alternator belt. yeah, no intercooler for now, but can always integrate it later.

any comments, suggestions? (besides dropping it and going turbo?

Re: how to supercharge a ca18det?

Have anyone done both supercharger and turbo on ca18det?

that would be interesting

that would be interesting

- ILOVESILVIA(S13)

- Posts: 521

- Joined: Tue Sep 09, 2003 2:43 pm

- Car: 93 Ca18det Hatch, 03 Subaru WRX Wagon (daily), Subaru Legacy Limited GT (daily)

- Location: Raleigh, North Carolina

Re: how to supercharge a ca18det?

still not over this. Hope to retrofit a supercharger on the ca18 some day

- Valvebounce

- Posts: 28

- Joined: Wed Sep 30, 2009 11:23 pm

- Car: Datsun 1200, Datsun 510, NIssan WGC34 Stagea, Datsun Sunny PB310

- Location: Christchurch New Zealand

- Contact:

Re: how to supercharge a ca18det?

Supercharging is fun!

I have An S/C14 on my datsun A15. Drib=ven at 1:1, it makes 10-11psi boost. I run drawthrough with no intercooler. Car has gone 14.1 E/T @96mph.

I also have a Datsun 510 "one day" project. I've got a CA18det for that, to which I'm going to fit an IHI screw blower off a 2.3ltr mazda millenia millercycle engine. (I've also got a 4 port head for it)

Dont let the naysayers put you off.

Fistly, you need to find a suitable sized blower. An Eaton M62 will be a good size. I have one here that came off a nissan frontier VG33eR truck.

Then you need to mount it to your engine. Best bet is to dump the AC. And use the flange on the block to mount it to. Making sure that the supercharger is mounted perfectly parrallel to the engine crank. And where the pulley lines up with the crank pulley.

Blower make a nice flat power curve. I have a mate who has an S/C14 on a CA18det in a datsun 1200 coupe. It made 200hp atw on 9psi. Not spectacular. BUT, it has huge torque. (Off idle) and it can destroy tyres at will. That car has gone 13.7 in the quarter, with serious traction issues.

I have An S/C14 on my datsun A15. Drib=ven at 1:1, it makes 10-11psi boost. I run drawthrough with no intercooler. Car has gone 14.1 E/T @96mph.

I also have a Datsun 510 "one day" project. I've got a CA18det for that, to which I'm going to fit an IHI screw blower off a 2.3ltr mazda millenia millercycle engine. (I've also got a 4 port head for it)

Dont let the naysayers put you off.

Fistly, you need to find a suitable sized blower. An Eaton M62 will be a good size. I have one here that came off a nissan frontier VG33eR truck.

Then you need to mount it to your engine. Best bet is to dump the AC. And use the flange on the block to mount it to. Making sure that the supercharger is mounted perfectly parrallel to the engine crank. And where the pulley lines up with the crank pulley.

Blower make a nice flat power curve. I have a mate who has an S/C14 on a CA18det in a datsun 1200 coupe. It made 200hp atw on 9psi. Not spectacular. BUT, it has huge torque. (Off idle) and it can destroy tyres at will. That car has gone 13.7 in the quarter, with serious traction issues.

Re: how to supercharge a ca18det?

at last! i'm not the only one with this idea

Isn't the IHI twinscrew somewhat a big blower for the CA18? why not the traditional roots route?

I can't imagine how an M62 off a frontier can be mounted inplace of the A/C....btw, I'd like to keep AC, however can remove the P/S This is why I was toying around with placing it instead of the intake plenum.

This is why I was toying around with placing it instead of the intake plenum.

What do you think of an M45? too small?

200HP is what I'm after.

btw, I'm still looking for an M62, have you considered selling your unit?

Isn't the IHI twinscrew somewhat a big blower for the CA18? why not the traditional roots route?

I can't imagine how an M62 off a frontier can be mounted inplace of the A/C....btw, I'd like to keep AC, however can remove the P/S

What do you think of an M45? too small?

200HP is what I'm after.

btw, I'm still looking for an M62, have you considered selling your unit?

- Valvebounce

- Posts: 28

- Joined: Wed Sep 30, 2009 11:23 pm

- Car: Datsun 1200, Datsun 510, NIssan WGC34 Stagea, Datsun Sunny PB310

- Location: Christchurch New Zealand

- Contact:

Re: how to supercharge a ca18det?

Yes it it's for sale.

I'm in New zealand though.

I just remembered that I know a chick who has a ca18de in a datsun 620 ute with an S/C14 that goes hard also.

I'm too drunk right now to crunch the numbers, But If I remeber to stop by here tommorrow I'll try run some numbers for you.

I'm in New zealand though.

I just remembered that I know a chick who has a ca18de in a datsun 620 ute with an S/C14 that goes hard also.

I'm too drunk right now to crunch the numbers, But If I remeber to stop by here tommorrow I'll try run some numbers for you.

Re: how to supercharge a ca18det?

yeah, noticed that you're from NZ

lol. Ok )

)

lol. Ok

Re: how to supercharge a ca18det?

btw, how much you want for the s/c? can't PM you..

- float_6969

- Moderator

- Posts: 19857

- Joined: Mon Aug 26, 2002 1:55 pm

- Car: CA18DET swapped 1995 Nissan 240sx (too many mods to list)

2015 SV Leaf w/QC & Bose (daily) - Location: Topeka, Kansas

- Contact:

Re: how to supercharge a ca18det?

For 200hp, I would think the M45 would be the way to go, but it won't leave you any head room either. The M62 will give you that headroom if you want it, but you will run into placement issues as most M62's have a long nose on them.

Re: how to supercharge a ca18det?

I had an opportunity to source an m45 locally, but having no room for some extra hp sucks. Shall continue looking for an m62

Haven't got any dimensions of the frontier M62, but I think it's possible to install inplace of the upper intake manifold (came across a twincharged SR20 with similar placement) and try running it off the alternator belt (one belt for alt. and s/c). what do you think?

Haven't got any dimensions of the frontier M62, but I think it's possible to install inplace of the upper intake manifold (came across a twincharged SR20 with similar placement) and try running it off the alternator belt (one belt for alt. and s/c). what do you think?

- Valvebounce

- Posts: 28

- Joined: Wed Sep 30, 2009 11:23 pm

- Car: Datsun 1200, Datsun 510, NIssan WGC34 Stagea, Datsun Sunny PB310

- Location: Christchurch New Zealand

- Contact:

Re: how to supercharge a ca18det?

Okay, lets smash out some number.

I did a quick google, And found a map here http://www.capa.com.au/eaton_m45data.htm

Anyway, that show an M45 spinning to 14000rpms.

And M45 pumps 45cuI per rev. (Or so I've been led to believe?)

That makes .73755litres per rpm.

So at a max RPM of 14000, (As per the map in the above link) that makes 10325.7 litres of air.

Take a Ca18. 1800cc, div by 2 = .9 litres of air.

Pick your redline. Say 7000.

=6300 litres of air.

Now if we divide 10325 by 6300 we get 1.6388888888 This figure is our boost ratio.

Boost ratio X 14.7 = 23.8886

minus 14.7 gives us a figure of 9.18 psi of boost.

Now,

Given that in my experience, the numbers crunched on a calculator have never matched what the actual boost figure was, I'd say the M45 is a little bit small. If an M45 pumped the actual boost I just calc'd out, you'd still need to figure things like pumping losses, and the heat generated. Plus figure in parasitic losses.

But even with an M45, the engine would be fun to drive.

The other factor to consider is I just drank a bottle of bubbles. So I might have fvcked up the numbers. lol

But I'll share with you the following link- http://datsun1200.com/modules/newbb/vie ... mpost35090

That was the formula is used to nut out the ablove equations.

I did a quick google, And found a map here http://www.capa.com.au/eaton_m45data.htm

Anyway, that show an M45 spinning to 14000rpms.

And M45 pumps 45cuI per rev. (Or so I've been led to believe?)

That makes .73755litres per rpm.

So at a max RPM of 14000, (As per the map in the above link) that makes 10325.7 litres of air.

Take a Ca18. 1800cc, div by 2 = .9 litres of air.

Pick your redline. Say 7000.

=6300 litres of air.

Now if we divide 10325 by 6300 we get 1.6388888888 This figure is our boost ratio.

Boost ratio X 14.7 = 23.8886

minus 14.7 gives us a figure of 9.18 psi of boost.

Now,

Given that in my experience, the numbers crunched on a calculator have never matched what the actual boost figure was, I'd say the M45 is a little bit small. If an M45 pumped the actual boost I just calc'd out, you'd still need to figure things like pumping losses, and the heat generated. Plus figure in parasitic losses.

But even with an M45, the engine would be fun to drive.

The other factor to consider is I just drank a bottle of bubbles. So I might have fvcked up the numbers. lol

But I'll share with you the following link- http://datsun1200.com/modules/newbb/vie ... mpost35090

That was the formula is used to nut out the ablove equations.

Re: how to supercharge a ca18det?

great! Thanks! I'll llook into this.

Re: how to supercharge a ca18det?

the other thing I like about superchargers is a smaller boost rate, which is safer for the engine?

- Valvebounce

- Posts: 28

- Joined: Wed Sep 30, 2009 11:23 pm

- Car: Datsun 1200, Datsun 510, NIssan WGC34 Stagea, Datsun Sunny PB310

- Location: Christchurch New Zealand

- Contact:

Re: how to supercharge a ca18det?

Superchargers are all about torque.

There's no need to rev the clacker off the engine to make power. It makes an engine behave like a bigger engine. Just without the extra weight.

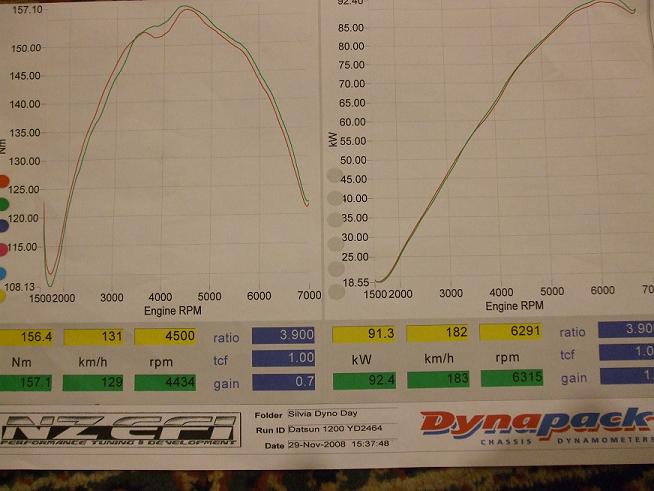

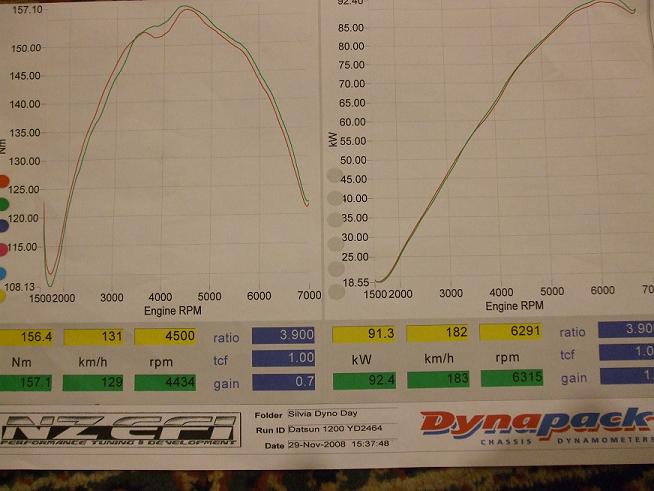

Heres a pic of my dyno sheet to give you an idea of how linear the power delivery is

Not bad considering it's an 8 valve non crossflow 1500 pushrod engine.

Given the lower boost numbers you'l run with a a blower, you might be able to run de pistons. (If your tune allows it)

There's no need to rev the clacker off the engine to make power. It makes an engine behave like a bigger engine. Just without the extra weight.

Heres a pic of my dyno sheet to give you an idea of how linear the power delivery is

Not bad considering it's an 8 valve non crossflow 1500 pushrod engine.

Given the lower boost numbers you'l run with a a blower, you might be able to run de pistons. (If your tune allows it)

Re: how to supercharge a ca18det?

I like that power delivery, that's my goal with the ca18..so an eaton m90 with small boost ratio would be the best option - lots of air @ lower boost? or an overkill, and if so, why?

btw, why would I need DE pistons? isn't the turbo prepped engine good for supercharging? yes, the compression ratio is lower than for an NA engine, but it's still being boosted, right? I'm not arguing, just want to learn something new

btw, why would I need DE pistons? isn't the turbo prepped engine good for supercharging? yes, the compression ratio is lower than for an NA engine, but it's still being boosted, right? I'm not arguing, just want to learn something new

- Valvebounce

- Posts: 28

- Joined: Wed Sep 30, 2009 11:23 pm

- Car: Datsun 1200, Datsun 510, NIssan WGC34 Stagea, Datsun Sunny PB310

- Location: Christchurch New Zealand

- Contact:

Re: how to supercharge a ca18det?

I'm just saying that with a lower target boost, you mightn't need as low of a CR.

The chick I know who runs a CA18de+Z in her 620 ute repoerted an increase in power after the det motor ran a bearing, and they replaced the motor with a DE instead. (Well tbh her now ex husband told me that) Although they did have to rotate the CAS clockwise a bit to quell the engine from pinging. But to be fair it is only running a standard det ecu and maps. Running a big blower will incur a greater parasitic loss. But (if the eaton size is in fact the displacement in cubes as I've been led to believe) 1.475 litres per rev would give far superior performance.

However, I'f your blower isn't clutched, you'd really be best to run the TB on the inlet side of the SC.

I plan to mount my IHI screw charger on the left side of the engine, above the headers. But sh1t is going to be tight.

The chick I know who runs a CA18de+Z in her 620 ute repoerted an increase in power after the det motor ran a bearing, and they replaced the motor with a DE instead. (Well tbh her now ex husband told me that) Although they did have to rotate the CAS clockwise a bit to quell the engine from pinging. But to be fair it is only running a standard det ecu and maps. Running a big blower will incur a greater parasitic loss. But (if the eaton size is in fact the displacement in cubes as I've been led to believe) 1.475 litres per rev would give far superior performance.

However, I'f your blower isn't clutched, you'd really be best to run the TB on the inlet side of the SC.

I plan to mount my IHI screw charger on the left side of the engine, above the headers. But sh1t is going to be tight.

Re: how to supercharge a ca18det?

So making the compression higher resulted in better performance, interesting...

ahh yes, about the TB, I'm planning on placing it before the SC inlet, so basically the SC will turn into part of the manifold, thus reducing SC whine (I was told that created vacuum will cancel the noise), and provided that it's no clutch unit, that's about the only good place to place it. Not sure though what runner length will be required or maybe the lower intake manifold (4 port euro) length would be ok, yet to figure out.

I posted some pics previously, this is the placement idea:

it's from a KA24E, but essentially the same concept.

ahh yes, about the TB, I'm planning on placing it before the SC inlet, so basically the SC will turn into part of the manifold, thus reducing SC whine (I was told that created vacuum will cancel the noise), and provided that it's no clutch unit, that's about the only good place to place it. Not sure though what runner length will be required or maybe the lower intake manifold (4 port euro) length would be ok, yet to figure out.

I posted some pics previously, this is the placement idea:

it's from a KA24E, but essentially the same concept.

- Valvebounce

- Posts: 28

- Joined: Wed Sep 30, 2009 11:23 pm

- Car: Datsun 1200, Datsun 510, NIssan WGC34 Stagea, Datsun Sunny PB310

- Location: Christchurch New Zealand

- Contact:

Re: how to supercharge a ca18det?

That would work a treat.

You'd ideally want to run water/meth injection to keep the combustion nice and stable under full load.

ONe other thing some mates of mine have found is that you need to mount the AFM a little bit further away from the charger, as the turbulence created can intefere with the afm, and cause it to give eronious readings to the ecu. Although having the tb in between might act as a diffuser for said turbulance.

You'd ideally want to run water/meth injection to keep the combustion nice and stable under full load.

ONe other thing some mates of mine have found is that you need to mount the AFM a little bit further away from the charger, as the turbulence created can intefere with the afm, and cause it to give eronious readings to the ecu. Although having the tb in between might act as a diffuser for said turbulance.

- float_6969

- Moderator

- Posts: 19857

- Joined: Mon Aug 26, 2002 1:55 pm

- Car: CA18DET swapped 1995 Nissan 240sx (too many mods to list)

2015 SV Leaf w/QC & Bose (daily) - Location: Topeka, Kansas

- Contact:

Re: how to supercharge a ca18det?

Higher compression will always make more power given 2 constants: the engine is physically able to handle the increase in power, and you are running a high enough octane fuel to prevent pre-ignition, which leads to knock.

This principal is why I'm able to run 10.2:1 compression ratio and an 25psi of boost. I have the engine strength to handle the power, and I'm running E85, which has an octane rating of around 100, which is high enough to prevent the combustion gasses from igniting until the spark says so, LOL.

This principal is why I'm able to run 10.2:1 compression ratio and an 25psi of boost. I have the engine strength to handle the power, and I'm running E85, which has an octane rating of around 100, which is high enough to prevent the combustion gasses from igniting until the spark says so, LOL.

Re: how to supercharge a ca18det?

float, I recently came across SDS EFI's website and found its tech section very useful, so I can see what you're talking about lol. unfortunately we don't have good fuel around here, mostly it's stated as 92-95-98 octane rating but turns out to be lower than that..so I guess no high compression for me, basically always running 92 octane. so I'll have to stick with 8-8.5 compression ratio (hope my ca18's got that).

Valvebounce, also I'll be leaving stock AFM and idle system in favor of Megasquirt provided 2.5 bar map sensor and GM IAC valve; would the turbulence issue affect MAP sensor as well? iirc, it only measures pressure. Also I'll place the air temp sensor (NTC style, looks like the stock AFM sensor part) in front or the TB.

other thing I've been thinking about - placement of the TB; Frontier/Xterra's SC inlet is on the left back side of the unit, and I can either have piping from the SC to a remote location and place TB there (such as in above picture), or place the TB right before the SC inlet, and have piping over cam covers like in FWD CA18 version, this would allow routing the air duct piping to the stock airbox location and save the battery in its factory location but will leave me figuring out the throttle cable routing. any suggestions?

Valvebounce, also I'll be leaving stock AFM and idle system in favor of Megasquirt provided 2.5 bar map sensor and GM IAC valve; would the turbulence issue affect MAP sensor as well? iirc, it only measures pressure. Also I'll place the air temp sensor (NTC style, looks like the stock AFM sensor part) in front or the TB.

other thing I've been thinking about - placement of the TB; Frontier/Xterra's SC inlet is on the left back side of the unit, and I can either have piping from the SC to a remote location and place TB there (such as in above picture), or place the TB right before the SC inlet, and have piping over cam covers like in FWD CA18 version, this would allow routing the air duct piping to the stock airbox location and save the battery in its factory location but will leave me figuring out the throttle cable routing. any suggestions?

Re: how to supercharge a ca18det?

btw, I'd like to thank everyone contributing to this topic, I've picked up a lot from here:)

- float_6969

- Moderator

- Posts: 19857

- Joined: Mon Aug 26, 2002 1:55 pm

- Car: CA18DET swapped 1995 Nissan 240sx (too many mods to list)

2015 SV Leaf w/QC & Bose (daily) - Location: Topeka, Kansas

- Contact:

Re: how to supercharge a ca18det?

Turbulance can still affect the MAP sensor. It causes a fluctuating signal, just like it does in a MAFS. The effect is less on a MAP based system, but it's still there.

You want the TB as close to the S/C inlet as you can. If you move it too far away, there will be a lag between when you open the throttle and when you get boost. Kinda defeats the purpose of a S/C, LOL.

You want the TB as close to the S/C inlet as you can. If you move it too far away, there will be a lag between when you open the throttle and when you get boost. Kinda defeats the purpose of a S/C, LOL.