1) The air inlet box between the air cleaner and the throttle body was removed for ease of access. The knock sensor is located in the black hole just above the word “Removed” in the picture.

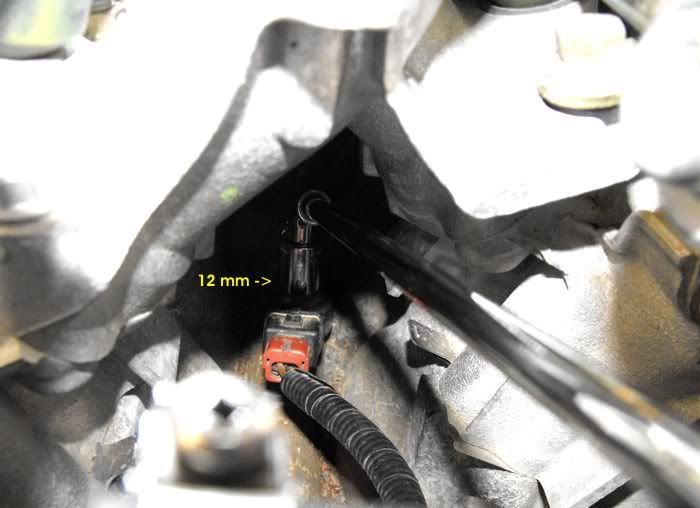

2) To reach under the plenum a 12 or 14-inch socket wrench extension is needed. My first attempt at using a universal joint with a 3/8-drive extension was unsuccessful. The “no name” universal joint was too loose and it would twist off of the bolt when I applied torque. I was about to give up on the whole operation when I decided to go to Sears to look into different tools. As it turned out, I purchased a 14-inch ¼ drive extension and ¼ inch universal joint. I already had a 12mm ¼ drive socket in my toolbox. The universal joint seemed to make a big difference. The Sears joint is not too easily moved. It could be positioned at the exact angle needed to remove the bolt without wobble. The universal joint and extension are pictured below.

3) A pick (dentist looking tool) that I purchased from Harbor Freight was used to release the knock sensor plug clip as shown in the following picture.

4) The knock sensor block mounting area was brushed to remove any corrosion. The angle-handled brush in the following picture was used to clean the mounting area.

1995 Maxima Check Engine Code 34