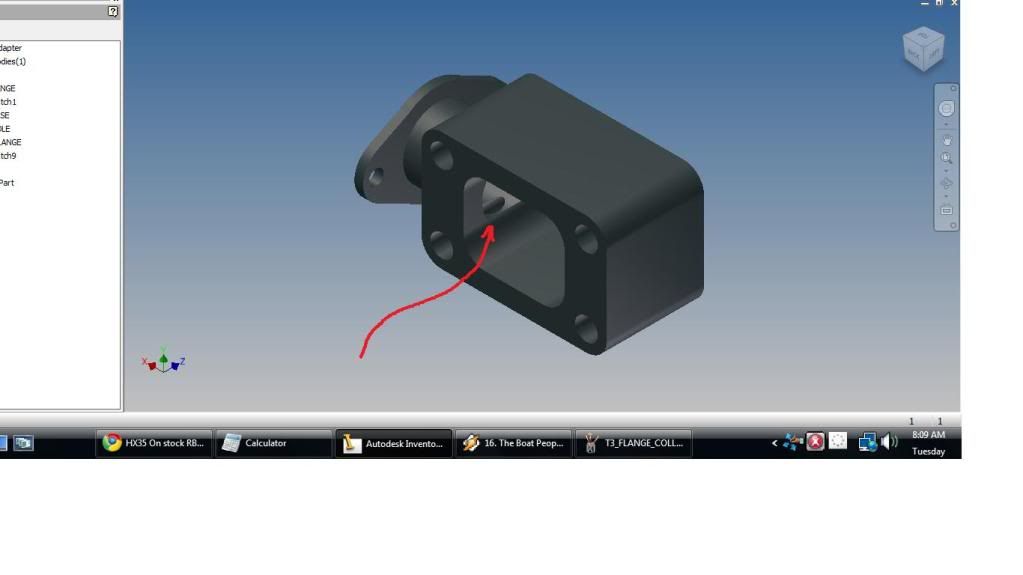

This is it loosely mounted.

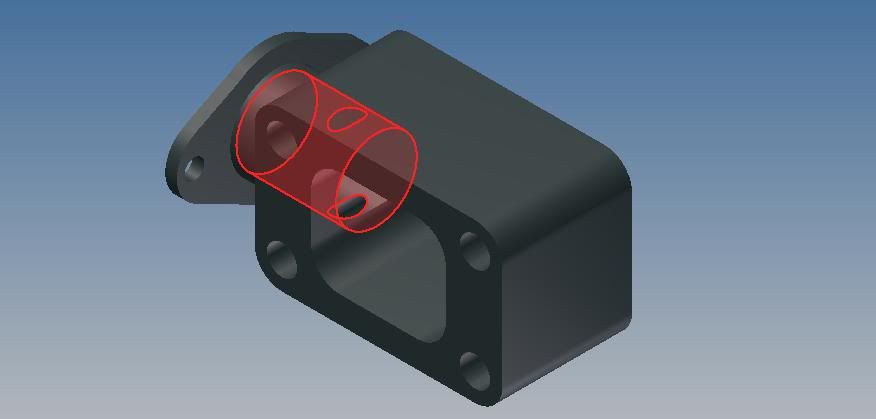

Notice the wastegate flange is facing the compressor housing. ( I take %100 fault, but thats what I get for not double checking my self)

Note the s*** welds. I preheated and got pretty good penetration in some spots, but this is something I should definitely leave to a professional I will grind the welds off this weekend and send it out to get re-done.

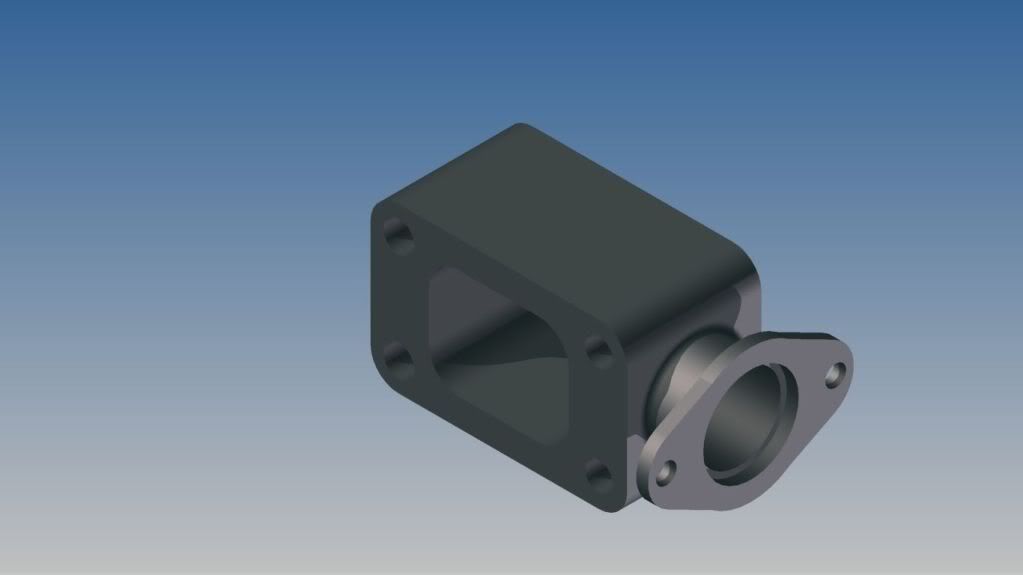

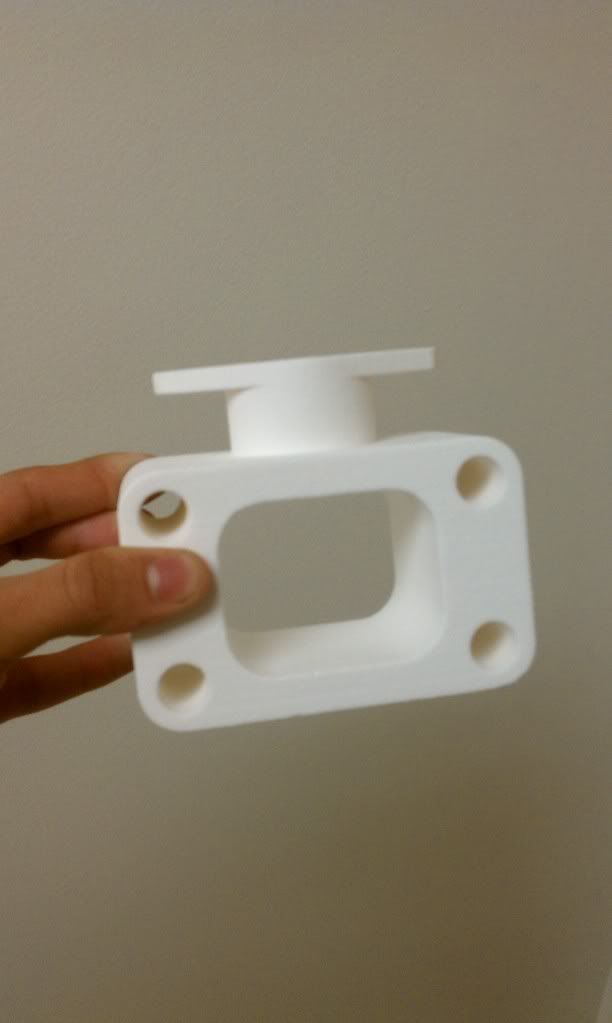

This is the adapter I used. I would have bolted it on to the Manifold but the wastegate adapter doesn't leave any space for a bolt or nut. When I take it apart I will show you guys what I mean.

A picture of the car as it sits haha.

Please let me know what you guys think. Remember I'm not a professional by any means. I'm also sending it out to get re-welded. So far it seems it will fit and work ( this was my main concern).