I know, I know, another thread, but I thought I would pull this part thread out of the 320 Clutch Replacement as we will focus only on an engine rebuild. And at least for know just the block. Sorry, but I have a rebuilt head that came with the '62 320 parts truck, so we are looking to cut cost and not corners and will use this over one over rebuilding the '64s head.

So a busy week on the phone, on line, and braving the crazy holiday traffic here in KCKS and KCMO. So let's concentrate on the parts list with supporting references. I have some info, but not all so here's the list starting from the head gasket down to the pan -

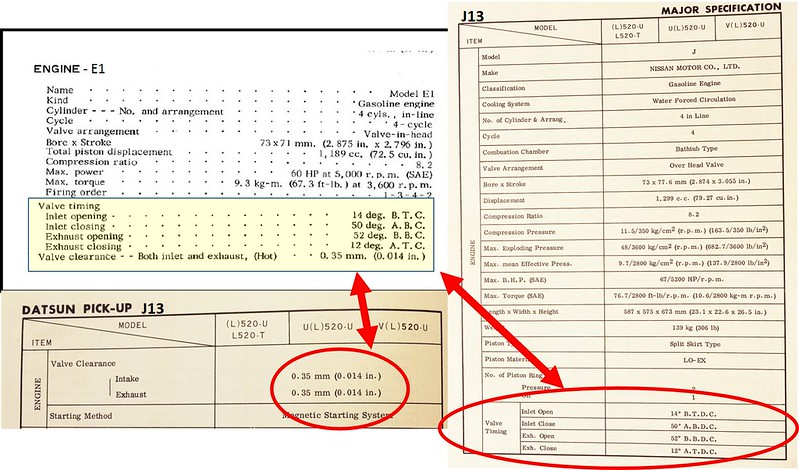

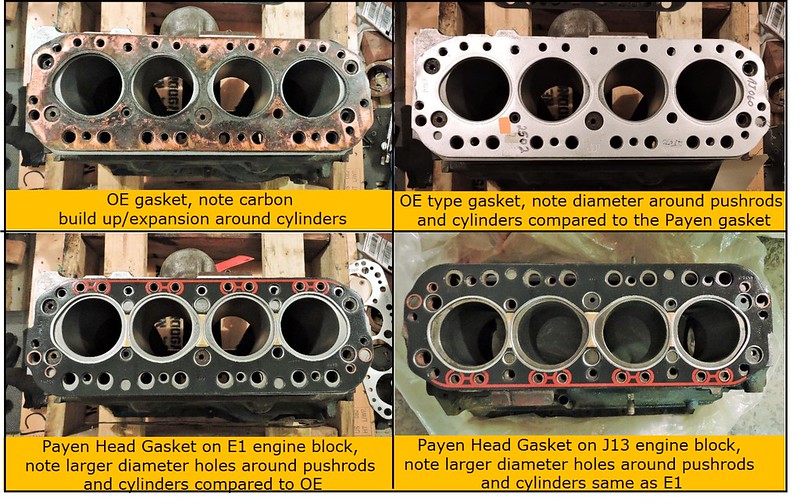

Head Gasket - from eBay with a 320 engine gasket set or VB(1-732)/MM (I'd recommend the Payen HG from MM on this one, very nice!)

Head Studs - going with what I have, measured and within tolerance. The studs from the MGA or 3 Main Bearing MGB should work, pretty sure the are all the same 3 or 5 main bearing. 6 1/4 and 4 1/2 are the same measurements. Just make sure you measure/inspect before reassembly.

Pistons - keeping what I have, some time in the past someone put in J13 pistons. Ted at the machine shop said mine are fine and is cleaning these up. Farm net Mason Datsun does list a few alternative sources for pistons - link at bottom of thread.

Rings - See Hasting links below. The short- Yes available, new, no issues. The Loooooong....Called and talked to Dawn at Hasting up in Michigan. Yes, all E1 rings are available, new, and still made in all sizes STD, .010, .020, .030, .040, and .050. She gave me the number to a parts distribution warehouse - Jobber (JPW), know it well, here in KCMO. Talked to Austin, who confirmed everything from Dawn at Hastings. He in turn gave me a POC for couple of Hasting's dealers in KC area. Called and talked to Brad at Motorsports Kansas City, gave him the part number and credit card info....they should be in on Tuesday of next week.

-----Part number info-----

2C6714 is for chrome coat rings. I was told not to get these as the eventfully will start flaking. Soooooo went with part -

6714 this is for the cast iron rings. Heads up...You will need to add the 0x0 for the correct oversize ring set. I ordered 6714040, with the end three digits being the oversize of .040/.75mm. 6714 is the STD size part number.

Rods - keeping what I have and have not researched this one, sorry. Farm.net Mason Datsun does not list as an alternate source.

Rod Bearings - Available new through Clevite. Just need the size from Ted.

Main Bearings - Going with the ones from VB at .010 or .25mm. Supporting reference is from Farm.net Mason Datsun excerpt below and link at bottom of post.

Main Bearings - Alternate Sources

Datsun J13 engine Datsun 411 1965-1969

Datsun 520 1965-1969

Datsun 521 1965-1969 Identical

MG MGA 1600 MK1 1961-1962 Identical

MG Magnette MK4 1961-1962 Identical

Austin A60 1962-1969 Identical

Note that Clevite only has STD Main Bearings listed on page 566. With this we had to research compatible/alternate parts. So Clevite to Farm.net Mason Datsun for a little help and then to the VB catalog -- pick'n up the parts Tuesday.

Thrust washer - available through Clevite, but going with VB on this one too.

Timing Chain Tensioner - should be available at your local auto parts store, Napa for sure, or you can stay with VB or MM. You might have to tell you local parts store to look up a tensioner for a 520.

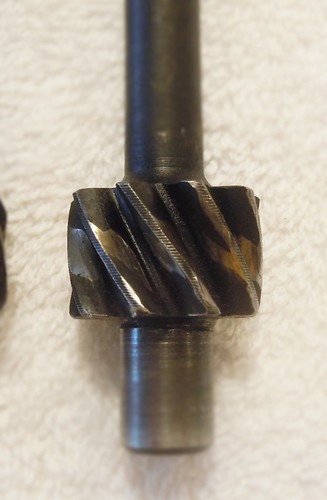

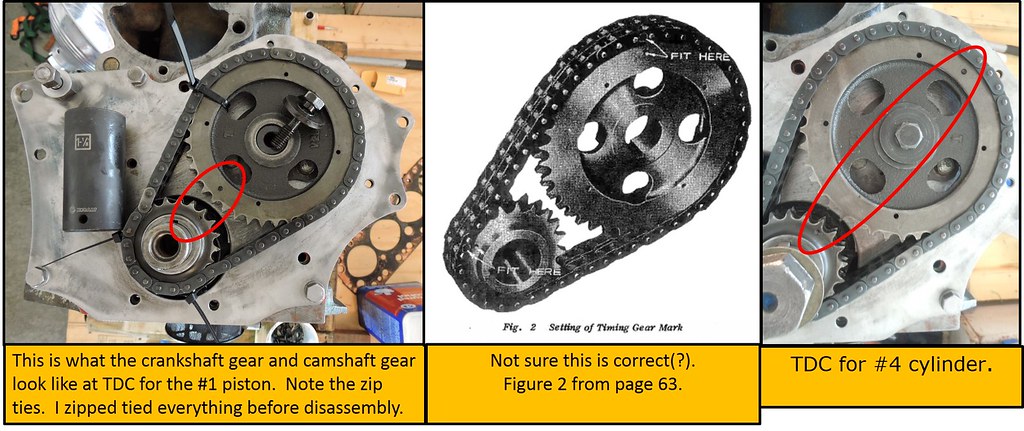

Timing Chain and Sprockets/Gears - again, available locally, ie Napa. And of course do not forget to tell them to look up a 520/J13 if they do not have a listing for a 320, which is highly likely. Napa does sell the sprockets and the chain separately.

Rear Graphite Rope - this is what the rear crank seal is/called. Should be available locally or at your industrial type distributor. You want to as for 3/8 inch graphite rope. It's sold by the foot or at least at Hanna Rubber here in KCMO.

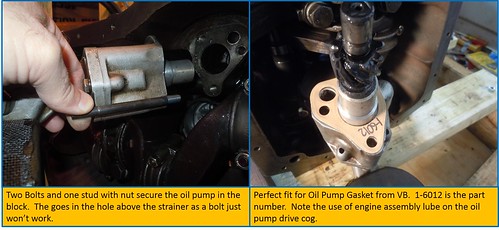

Oil Pump - yes a MGA / 3 main bearing MGB pump will work. Only difference is the oil pump neck to the strainer. OE is a side mount while the MGA is a top mount.

Front and rear main seals available on eBay with the complete engine gasket set for a 320 or 520 or you can get the two small short ones for the back and the long front one through either VB or MM.

External Links -

Farm.net Mason Datsun - http://www.farm.net/~mason/datsun/datsun-parts.html

VB = Victoria British - http://www.victoriabritish.com/icatalog/csc/t.aspx

MM = Moss Motors - http://www.mossmotors.com/Shop/ViewProd ... exID=36470

Clevite/Mahle - http://www.mahle-aftermarket.com/mahle_ ... e-bearings from here you'll need to click on the "download" link or try this direct link -

http://www.mahle-aftermarket.com/c12579 ... -10-07.pdf from here go to page 563 for Nissan. The E1 is listed in the measurement reference up front and then pages 565 and 566 list the bearing info for the E1.

NOTE the Main Bearing Set is only available in STD, so this where Farm.net/Mason/Datsun cross-reference is so important.

Hastings - http://www.hastingsmfg.com/RingFinderMa ... OCD=NISSAN Cars & Trucks&AddText=

Hasting on line pdf catalog - http://www.hastingsmfg.com/Master_Catal ... er2012.pdf from here go to page 176 for Piston Ring Number of 2C6714 and 6714. Page 309 list dimension and other auto applications for Part # 6714. Might take a look at the Do's and Don'ts up front in the online catalog - lot's of good information

Well that's about a week's worth of research, running around, and parts verification so hope this helps.

cheers

Li'l Truckie